Pre-painted Rolled steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

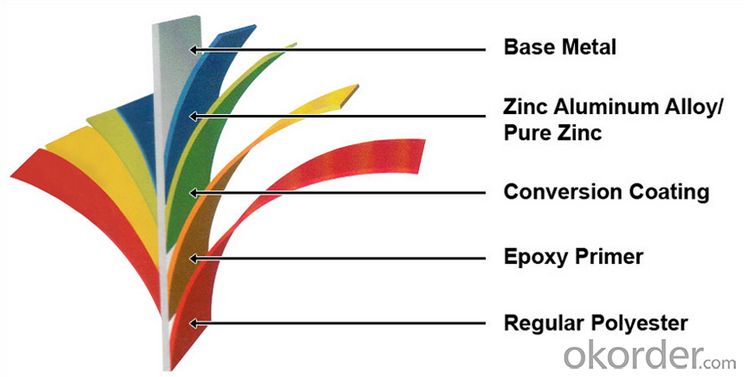

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different coil packaging materials used for steel coils?

- The different coil packaging materials used for steel coils include steel strapping, plastic strapping, stretch wrap, and wooden crates.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- steel wire has to be silver soldered, or brazed ,or spot welded, you can not solder it, with reg solder or a soldering iron, use a small torch, like a pencil torch,

- Q: also what are the factors of location of these steel plants

- I work for a pipe manufacturer in Birmingham, AL. We have multiple divisions including two specialized steel pipe divisions and a ductile iron pipe divisions. As far as the steel pipe divisions, they purchase skelp from suppliers. All of the steel that they purchase is of domestic manufacture, and is very expensive. As for the ductile iron division, we manufacture our own iron for the pipe. To get the iron that we need, we buy scrap in the form of cars, refrigerators, rejected pipe that we produce, etc. It is shredded in one part of the plant, and then melted and cast as a new product. This has become very problematic, scrap prices have skyrocketed in the US due to the large demand from countries such as China who gobble all of the material because they need great quantities of it. So, to answer your question, we get steel from recycling and then some raw iron ore. As to where we get the raw ore, I'm not 100% sure.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- How to make it rust faster ? Adding oxygen to the water - bubbling air through it. Raising the temperature should make the reaction go faster, but I believe it also reduces the amount of dissolved gas. Adding salt, or an ionic compound like an acid, will accelerate electrochemical corrosion. That usually requires a less active metal, like copper, in contact with the steel, but variations in the composition of the steel may be sufficient to promote corrosion.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You could but you will have to run lower pressures and speed and thus lower power output. You should do some research the Me 262 the Nazi's built. I don;t know but I think they used steel. That's why the engine had to be serviced every few hours of flight.

- Q: What are the dimensions of steel coils used in the furniture industry?

- The dimensions of steel coils used in the furniture industry can vary depending on the specific application and requirements of the furniture manufacturer. However, typically, steel coils used in the furniture industry have dimensions ranging from 0.20mm to 3.00mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, but it is commonly around 1000mm to 3000mm. These dimensions allow for flexibility in shaping and forming the steel coils into various furniture components such as frames, springs, and structural supports.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are commonly used to make brake pads and brake rotors. Steel coils are processed and shaped into the required forms to create these essential components, which play a crucial role in the braking system's functionality and performance.

- Q: Can steel coils be used in marine environments?

- Yes, steel coils can be used in marine environments, but proper precautions need to be taken to prevent corrosion. Steel is prone to corrosion when exposed to moisture and saltwater, which are common in marine environments. To counteract this, the steel coils can be treated with protective coatings, such as galvanization or painting, to create a barrier between the steel and the corrosive elements. Additionally, regular maintenance and inspections should be performed to identify any signs of corrosion and take appropriate action to prevent further damage. By implementing these measures, steel coils can be effectively used in marine environments while minimizing the risk of corrosion and ensuring their durability and performance.

- Q: Why is the steel tape tape head not fixed?

- It makes sense to be irregular;You can see the standard ruler of steel roll head is a gap, when you take the time to object quantity, the head will indent the gap, so you measure is the size of the head from the head of steel;When you hook the object, the head will pull apart and you'll take the dimension from the end of the steel head.

Send your message to us

Pre-painted Rolled steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords