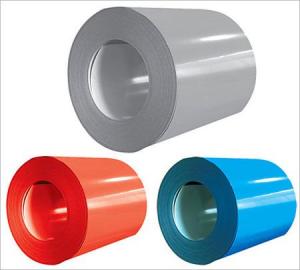

Prepainted Hot-Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

G550, Z60g/㎡, BMT 0.33MM, RAL9010, TOP coating: 22-25micronsSIZE MOQ0.35mm (TCT)*1200mm*C 60MTSFOB CHINA USD870/MT (Price is negotiable if u r interested)PAYMENT: 100% T/T BEFORE SHIPMENT and balance againt InvoiceSHIPMENT: 60 days After getting the payment bank slipLoading port: Tianjin, China

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they serve as the core of the transformer. The coils are wound around the steel core to create an electromagnetic field that efficiently transfers electrical energy from one coil to another. The steel coils help to increase the magnetic flux and enhance the efficiency of the transformer, allowing for the transformation of electrical voltage levels.

- Q: How do steel coils compare to other materials in terms of strength?

- Steel coils are renowned for their remarkable strength and durability, rendering them among the most robust materials obtainable in the market. In comparison to alternative materials like aluminum or plastic, steel coils demonstrate unparalleled strength and resilience against deformation or breakage. Due to the elevated tensile strength of steel, coils can withstand substantial loads, thereby rendering them perfect for diverse industrial uses, encompassing construction, automotive manufacturing, and the production of heavy machinery. Moreover, steel coils possess exceptional fatigue resistance, enabling them to endure repetitive stress and strain without compromising their structural integrity. This strength advantage positions steel coils as the preferred choice for applications that prioritize reliability and safety.

- Q: What are the challenges in coil recoiling for high-strength steel?

- One of the main challenges in coil recoiling for high-strength steel is the control and management of residual stresses. High-strength steel has a tendency to retain significant levels of residual stresses, which can lead to coil distortion or springback during recoiling. This requires careful process optimization and control to minimize these effects. Additionally, the high strength of the steel can make it more susceptible to cracking or damage during recoiling, necessitating precise handling techniques and equipment. Overall, the challenges lie in achieving uniform coil geometry, minimizing residual stresses, and avoiding any potential damage to the high-strength steel during the recoiling process.

- Q: What are the different finishes available for steel coils?

- There are several different finishes available for steel coils, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What are the major global steel coil markets?

- The primary concentration of major global steel coil markets lies in regions that possess significant industrial and manufacturing sectors. Key markets encompass North America, Europe, and Asia-Pacific. In North America, particularly the United States, the steel coil market holds substantial importance due to its large automotive industry and construction sector. The demand for steel coil in this region is propelled by the production of automobiles, infrastructure development, and residential construction. Europe stands as another crucial market for steel coil, with countries like Germany, Italy, and France acting as major consumers. The demand for steel coil in this region is driven by the automotive industry, construction sector, and machinery manufacturing. Asia-Pacific, specifically China, holds the position of the largest global market for steel coil. China's flourishing economy, rapid urbanization, and infrastructure development have resulted in a massive demand for steel coil. Alongside this, other countries in the region such as Japan, South Korea, and India also possess substantial steel coil markets due to their industrial and construction activities. Furthermore, emerging markets in Latin America, the Middle East, and Africa are witnessing a surge in demand for steel coil. These regions are experiencing economic growth and urbanization, leading to an increase in construction and infrastructure projects. In conclusion, the major global steel coil markets are propelled by industrial and manufacturing activities, infrastructure development, and construction projects in various regions across the globe.

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches (0.13 mm) to 0.250 inches (6.35 mm).

- Q: I have a need to connect various stainless steel tubes and fitting together and was wondering how to do it. I know a TIG welder is an option but have heard rumors that there is a way to solder it in much the same way you affix copper pipe. Perhaps with higher heat and different flux. I need step by step and maybe suppliers of the materials. Thanks in advance and please I do not need the call a plumber answers as I've gotten in the past

- Compression Ferrel connections are the best. for small diameter pipe and tubing. A local hardware shop can supply you with the necessary parts and pieces and can also give you a step by step procedure/self help brochure. This will also allow you to install any valve or t or blank in the piping system. The only tools required will be wrenchs and a tube/piping cutter for this type of installation. Brazing is accomplished by heating the base metal and then the rod. There are different types of brazing rod such as brass, bronze etc.. you will also need a can of flux to coat the rod or you can buy the rod pre-coated. If the seam is flat metal you can use the heat from the brazing tip to make the filler rod follow the direction you want. This also includes vertical such as on an auto body. I would suggest practicing this in a safe area. Always utilize a fire extinguisher, brazing goggles, welding gloves and wear a long sleeve shirt for your protection.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being processed and shaped into sheets that are then stamped, cut, and formed to create the door's structure. The strength and durability of steel make it an ideal material for automotive doors, ensuring safety and protection for passengers.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

Prepainted Hot-Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords