Pre-painted Rolled Coil for Roofing Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

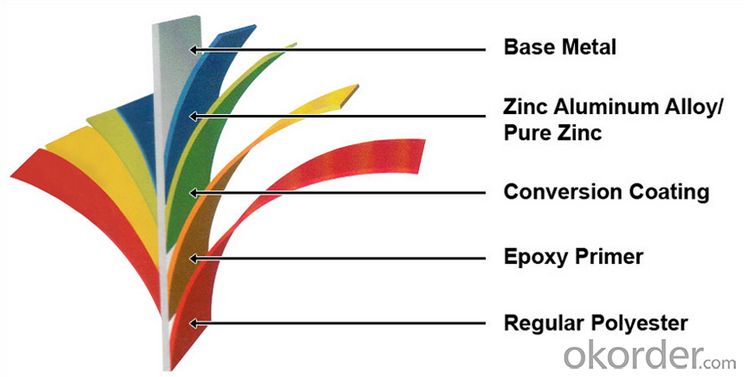

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery as they are commonly used to create the structural frames and components of the machinery. Additionally, steel coils are often used to manufacture cutting blades, conveyor belts, and various other parts that require strength and durability in the food processing industry.

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. On average, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: How are steel coils protected against bending and deformation?

- Steel coils are protected against bending and deformation through various measures. One common method is the use of protective packaging materials such as wooden crates or metal skids, which provide stability and support to prevent any bending or deformation during transportation or storage. Additionally, steel coils are often secured tightly using steel or plastic bands to maintain their shape and prevent any shifting or movement. These bands are strategically placed at regular intervals along the length and width of the coils to ensure even distribution of pressure and minimize the risk of bending or deformation. Moreover, steel coils can be further protected by placing them on a flat and level surface during storage or transportation. This helps to distribute the weight evenly and reduce the chances of any bending or deformation due to uneven pressure. In some cases, steel coils may also be coated with anti-corrosion agents to protect against moisture and rust, which can weaken the structure of the coils and lead to bending or deformation over time. Overall, a combination of proper packaging, secure fastening, and careful handling is essential to protect steel coils against bending and deformation, ensuring their structural integrity and quality.

- Q: What are the common surface treatments for steel coils?

- The common surface treatments for steel coils include galvanizing, painting, and coating with protective films.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: How do steel coils contribute to the HVACR industry?

- Steel coils play a crucial role in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) industry by serving as a primary component in various applications. These coils are typically made from a durable and corrosion-resistant material, such as stainless steel or galvanized steel, which ensures their longevity in demanding HVACR environments. One of the most common uses of steel coils in the HVACR industry is in air conditioning systems. These coils are responsible for transferring heat between the refrigerant and the surrounding air. The coils, often referred to as evaporator coils, absorb heat from the indoor air, cooling it down and removing moisture. They then release the heat outside through a condenser coil, allowing for efficient cooling and dehumidification of the air. Steel coils are also utilized in heat exchangers, which are vital components in HVACR systems. Heat exchangers transfer thermal energy between two fluids, allowing for efficient heating or cooling. Steel coils, often in the form of finned tubes, provide a large surface area for heat transfer and help enhance the overall efficiency of the system. Furthermore, steel coils are extensively used in the construction of ductwork, which is the network of channels that distribute conditioned air throughout a building. These coils are formed into various shapes and sizes to fit specific ductwork designs, ensuring optimal airflow and temperature control. Additionally, the durability and strength of steel coils make them suitable for withstanding the pressure and forces exerted by airflows in duct systems. In refrigeration systems, steel coils are integral to the process of transferring heat out of an enclosed space, such as a refrigerator or freezer. The coils, often referred to as condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. This allows for the cooling and preservation of perishable goods, making steel coils essential in the food service and cold storage industries. Overall, steel coils contribute significantly to the HVACR industry by enabling efficient heat transfer, optimal temperature control, and reliable operation of various HVACR systems. Their durability, corrosion resistance, and versatility make them a crucial component in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are transformed into structural components such as beams, plates, and girders. These coils are processed and shaped into the desired forms, providing the necessary strength and durability for the bridge's construction.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Carbon steels are alloys. This is evident in the carbon-iron phase diagram:

- Q: i heard steel type is good and i don't have any i have defeated all the trainers up to the icicle badge (i have got the icicle badge but not the one after) where can i get one?

- you can get a steelix at the cave just before the elite four. but if you have wifi, you can trade for one.

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

Pre-painted Rolled Coil for Roofing Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords