PRE PAINTED GALVANIZED STEEL CORRUGATED SHEETS /COATED STEEL COIL/PPGI/GI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

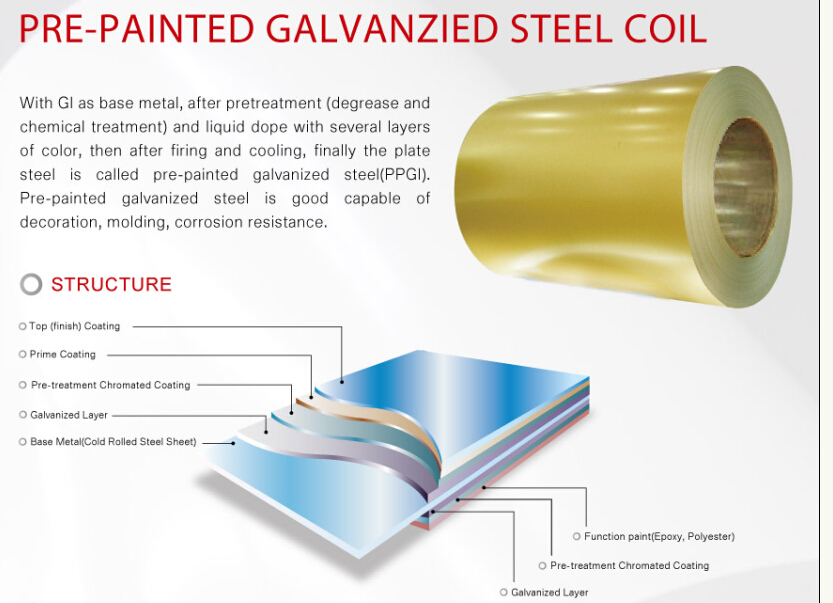

PREPAINTED GALVANIZED STEEL COILS

ZINC COATING:60g/m2 (-/+10g/m2)

COLOR: ACCORDING TO COLOR SAMPLE.

TOP COATING:5+13 MICRON, BACK COATING:5-7 MICRON;

COIL WEIGHT:3-5 ton

STANDARD:JIS G 3312

STEEL GRADE:CGCC

COIL ID:508mm

1.THICKNESS:-0.02/+0.02mm; WIDTH:0/5mm.ZINC COATING:+/-10g/m2;

2.TOLERANCE:+/-10% WITH QUANTITIES AND AMOUNT.

3.PACKAGE:FULL PACKED WITH ANTI-DAMP PAPER,IRON SHEET OUTSIDE.

4.SHIPMENT: GOODS WILL BE DELIVERED WITHIN 20 DAYS AFTER RECEIVING ADVANCE PAYMENT

5.TERMS OF PAYMENT: 20% TT IN ADVANCE,80% AGAINST COPY OF B/L. OR LC AT SIGHT

6.THIRD PARTY INSPECTION: SGS, INTERTEK,COTECNA ,BV. ANY EXPENSE ON INSPECTION(SUCH AS SGS,INTERTEK...) SHALL BE ON BUYER'S ACCOUNT.

- Q: I'm currently in an Estimating and Bidding class. I have to estimate two divisions for a multi-million dollar project. The project that I chose is around 6 million dollars and involves constructing a new gas/lighting building. I chose to estimate steel, and my question is, around how much out of the 6 million goes toward just the steel estimate? If it helps, this building is has two floors and is roughly about 100x70 feet. The building not wood construction, but rather steel and brick. How much of that 6 million would go into the steel? I'm not looking for anything exact, just roughly.

- That is a little tough to answer given the details. I will try to answer it as best I can. You can send me a message if you need further help and I can get some more details from you. If it is a 6 million dollar project, that is about $428/sf - (6 million divided by 14,000 sf). $428 is a little bit higher end then say, just a Walmart which is a block and steel box. Assuming you have a concrete slab on the first floor, metal deck on the second floor, with steel beams and open web joists framing, steel columns and steel roof framing with a metal deck roof.... you could be approx 10-15% of the total 6 million. Now, this would include the structural steel, not light gauge steel framing for walls. It sounds like you are looking for structural steel, not metal stud framing. Hopefully this helps, I can check back to this thread later to see if you've had to add any more details.

- Q: What are the different steel coil surface treatments?

- The different steel coil surface treatments include mill finish, galvanized, galvannealed, painted, and coated with various materials such as zinc, aluminum, or polymer.

- Q: who are the 7 best steel guitar players ever?

- I would have to put Lloyd Green and Buddy Emmons at the top of the list for virtuoso instrument playing mastery, technical expertise and versatility, adapting steel guitar to most any kind of music they were in studio to lay tracks for. Certainly, Pete Drake, and Weldon Myrick belong at the top of the best of the Nashville Session steel players for the last 50 years or more. While Leon McAuliffe and Roy Wiggins in the 1930's and 40's pioneered and paved the way for the country music steel guitarists coming along in the 50's 60's; we cannot leave this list without crediting the virtuoso technical and musical versatility of much later steel guitarists, whom have been the top-drawer, first-call session players in Nashville studios for the last 30 years or so. Namely, the best of the Nashville Session Steel players: Paul Franklin Jr. That's how my votes would stack-up, of the 7 best steel guitar players, ever! Thank you for a fun question to muse over and answer! Sincerely, Jazz Me109 PS: When editing what I've written above, I found it amusing and quite interesting that Paul Franklin, Jr. wound-up at the bottom of my list, when indeed he should be at the top of the list! I guess I feel that way about all of the steel guitar masters, that I've listed here, though! Oh well!...Have a great day! :)

- Q: I bought a stainless steel water bottle today. I really like it, but there is no drinking spout, it just has a lid that screws on and off, and an open hole to fill it and drink out of. Is this normal for these bottles? Or do they usually come with a spout to drink from? I don't want to look like an idiot at the gym drinking from this cool bottle with no spout if there's supposed to be one! haha.

- That's normal. I'm sure there are caps that you can get that have a built in spout though.

- Q: What are the different types of steel alloys used in coils?

- Coils commonly employ various types of steel alloys, each possessing unique properties and characteristics. Some frequently used types include: 1. Carbon Steel: As the most fundamental and widely utilized steel alloy in coils, it boasts low carbon content and renowned strength and durability. Carbon steel coils find extensive application in areas demanding high strength, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Comprising an iron, chromium, and other element alloy, stainless steel coils exhibit exceptional resistance to corrosion, formidable strength, and heat resistance properties. They are typically employed in scenarios where shielding against corrosion and staining is pivotal, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are formed by coating regular carbon steel with a layer of zinc, furnishing excellent corrosion resistance and safeguarding the underlying steel from rust. Commonly utilized in outdoor settings like roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are manufactured by incorporating diverse alloying elements like manganese, nickel, chromium, or molybdenum into carbon steel, thereby enhancing the steel's strength, hardness, and wear resistance. These coils frequently find application in industries necessitating high strength and toughness, such as machinery, tools, and construction equipment manufacturing. 5. Electrical Steel: Electrically specialized steel coils are designed explicitly for employment in electrical equipment like transformers and electric motors. These coils possess low electrical resistance and high magnetic permeability, facilitating efficient electricity conduction and magnetic field generation. Typically constructed from a silicon alloy, which enhances electrical and magnetic properties. In conclusion, the selection of a steel alloy for coils hinges upon the specific requirements of the given application, encompassing factors like strength, corrosion resistance, electrical conductivity, and heat resistance.

- Q: What is the strongest steel ever made.

- Wootz is laughable. A modern car spring has more tensile strength, not to mention better purity in manufacturing. Alpha B is right. My answer would be NS110. While wootz was the source of the original damascus steel. The manufacturing process was much like many crucible type steels of the past. And they were not used by japanese smiths. A traditional japanese sword was made from the ground up. Smelting the iron laden sand into Tamahagane. Which is a pumice like crude steel. It would be forged, and diamond powder would be applied and hammered into the skin. It would then be folded repeatedly to homogenize the blade. For what you are asking for now. I would say that 1/2 mild steel plate should work nicely.

- Q: How are steel coils used in the production of roofing and siding?

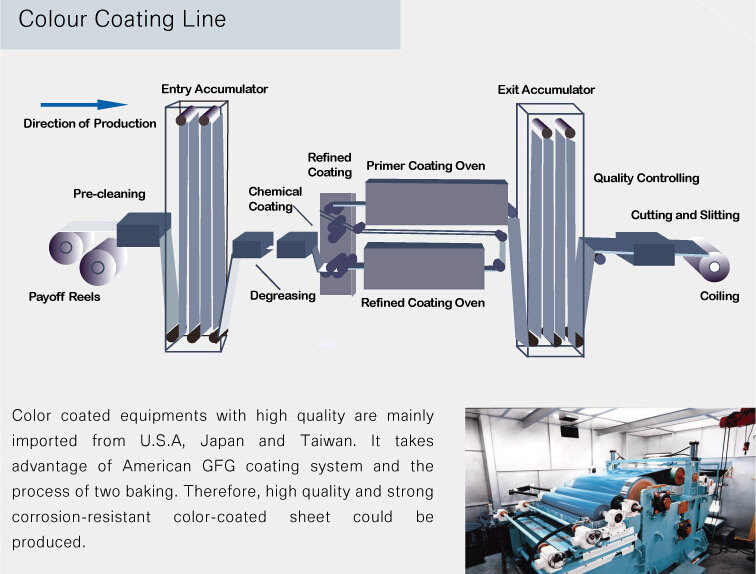

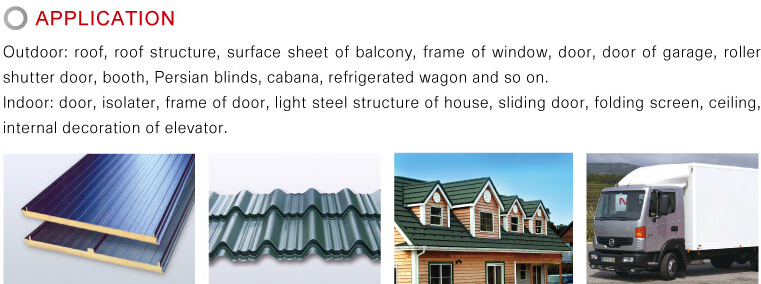

- Roofing and siding materials heavily rely on steel coils as a vital element. These coils, crafted from high-quality steel, undergo several processes to convert them into the final products used in roofing and siding. To start with, the steel coils are unwound and flattened to obtain a smooth steel sheet. Subsequently, this sheet is thoroughly cleansed to eliminate any impurities or contaminants. The cleansing procedure involves treating the steel's surface with chemicals and rinsing it meticulously to ensure a spotless and sleek surface. Following this, the steel sheet receives a protective layer to enhance its durability and resistance against corrosion. This coating can be executed through various techniques such as hot-dip galvanizing, electro-galvanizing, or applying a metallic or organic layer. The preferred method of coating depends on the desired properties and aesthetic requirements of the roofing or siding material. After the coating process, the steel sheet is shaped and formed into the desired structure and profile. For roofing purposes, the steel sheet is commonly corrugated or shaped into interlocking panels. This facilitates easy installation and guarantees a secure and weather-resistant roofing system. Similarly, for siding applications, the steel sheet can adopt various profiles like horizontal or vertical panels, shingles, or shakes. Once the steel sheet is formed, it may undergo additional treatments to improve its performance. This can involve applying a protective coat of paint or other finishes to enhance its appearance and resistance against fading, chipping, or scratching. The steel coils can also be embossed or stamped with patterns or textures to provide aesthetic appeal. In conclusion, steel coils play a vital role in the production of roofing and siding materials. They offer strength, durability, and weather resistance, making them an ideal choice for safeguarding structures from the elements. Furthermore, steel coils provide versatility in terms of shape, profile, and finish, allowing for a wide range of design options for roofing and siding applications.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: What are the safety regulations for steel coil production facilities?

- The safety regulations for steel coil production facilities typically include measures such as proper training and certification for employees, regular equipment inspections and maintenance, use of personal protective equipment, implementation of fire prevention and evacuation plans, adherence to hazardous material handling protocols, and compliance with occupational health and safety standards. These regulations aim to minimize the risk of accidents, injuries, and environmental hazards within the facility.

- Q: Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials. These materials help to reduce heat transfer and provide insulation to the steel coils, enhancing their thermal resistance.

Send your message to us

PRE PAINTED GALVANIZED STEEL CORRUGATED SHEETS /COATED STEEL COIL/PPGI/GI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords