Hot Sale Pre-Painted Galvanized (PPGI) Color Coated Steel/ Aluminized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Sale Pre-Painted Galvanized (PPGI) Color Coated Steel/ Aluminized Steel Coil

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

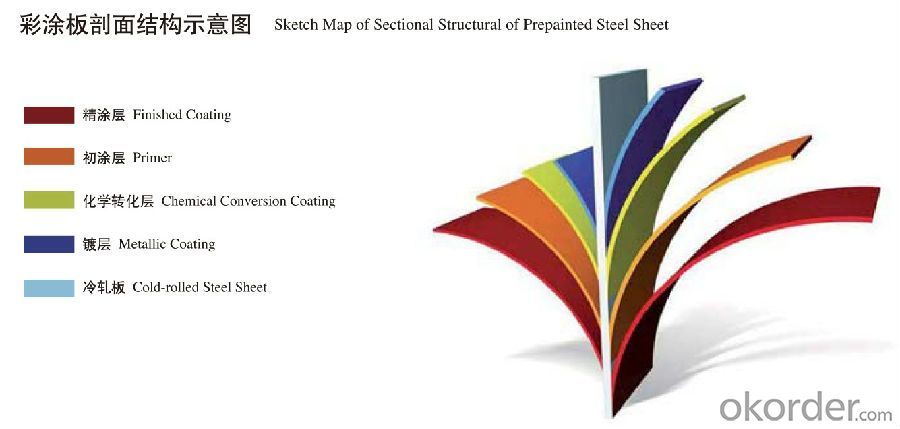

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4. Image:

Production

Production Line

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery as they serve as a key component for constructing the machine's framework and structure. The coils provide durability, strength, and resistance to the machinery, ensuring its reliability and longevity in food processing operations.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- I agree with everything that Lester said. Another thought is to consider starting on a lap steel guitar rather than a pedal steel - its related, a little easier to learn on, and less expensive. Once you get proficient on the lap steel, you can move up to the pedal steel. Good luck!

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry, which is a method of quantifying and measuring colors. Colorimetry involves the use of specialized instruments, such as spectrophotometers or colorimeters, to measure the color of an object in terms of its hue, saturation, and brightness. To inspect steel coils for color consistency, a colorimeter is typically used. This device emits light onto the surface of the steel coil and measures the amount of light reflected back. The reflected light is then analyzed and compared to a known standard color to determine if there are any deviations. The colorimeter measures color by breaking down the reflected light into different wavelengths and quantifying the intensity of each wavelength. This data is then converted into numerical values that represent the color of the steel coil. These numerical values can be compared to a predefined color standard to determine if the color of the coil falls within an acceptable range. To ensure accurate and consistent color measurement, colorimetry relies on standardized color spaces, such as CIE L*a*b* or CIE RGB, which define a specific range of colors. By using these standardized color spaces, colorimeters can provide objective and reliable measurements of color consistency. In the case of steel coils, color consistency is particularly important for industries where the appearance of the final product is crucial, such as automotive or appliance manufacturing. By inspecting the color of steel coils using colorimetry, manufacturers can ensure that the final products have a consistent and visually appealing appearance. Overall, colorimetry is an effective method for inspecting steel coils for color consistency. By using specialized instruments and standardized color spaces, manufacturers can accurately measure and compare the color of steel coils to predefined standards, ensuring that the final products meet the desired color specifications.

- Q: What is the average lifespan of a steel coil?

- The average lifespan of a steel coil can vary depending on several factors. These factors include the quality and type of steel used, the conditions in which the coil is stored or used, and the maintenance and care it receives. Generally, a well-maintained steel coil can last anywhere from 10 to 30 years. However, this is just an estimate and the actual lifespan can be shorter or longer depending on the aforementioned factors. For instance, if the steel coil is exposed to harsh environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be reduced. Regular maintenance and proper storage can significantly extend the lifespan of a steel coil. This includes ensuring that the coil is stored in a dry and protected environment, regularly inspecting and addressing any signs of corrosion or damage, and conducting routine cleaning and lubrication as needed. Ultimately, the average lifespan of a steel coil is dependent on various factors, and it is best to consult the manufacturer or industry experts for a more accurate estimate based on specific circumstances and conditions.

- Q: What are the different methods of welding steel coils?

- There are several methods of welding steel coils, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. MIG welding uses a consumable electrode wire and an inert gas as a shielding medium to create an arc and join the coils. TIG welding, on the other hand, uses a non-consumable tungsten electrode and a separate filler material to create the weld. Resistance welding involves applying pressure and passing an electric current through the coils to create a weld. Each method has its advantages and is chosen based on factors such as the type and thickness of the steel, desired quality, and production requirements.

- Q: What is the role of steel coils in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary material for constructing the tank's outer shell. These coils are shaped and welded together to form the tank's cylindrical structure, ensuring its strength, durability, and ability to withstand the pressure and weight of the stored materials.

- Q: Why is steel a stiff material?I'm doing a project on the use of steel in the construction of skyscrapers - and obviously, for the inner steel skeleton of a skyscraper the steel support beams and girders will have to be stiff so that they don't fall apart or the building doesn't shake due to wind or other natural forces.But in my research I've found that steel (mild steel to be more exact) is ductile and malleable, meaning it can be shaped fairly easily. However, how can steel ALSO be stiff - the definition of stiffness is the tendency to withstand bending and stretching - so my question is. How can this material be BOTH ductile/malleable, AND stiff? and why? :)Thank you in advance if anyone takes the time to answer this, would be appreciated - I'll give you 10 points straight away if the answers conclusive

- To say that steel can be bent and shaped fairly easily isn't quite true. It takes multiple tons of force to do so, requiring some very heavy machinery. I think you're confusing a couple of concepts. For example the idea of elastic modulus, versus rigidity Rigidity is the ability of a structure to resist a load. That depends not only on the elastic modulus, but on the size and design of the structure or object. You can build fairly rigid structures out of wood. For example roller coasters. Even though wood has a much lower elastic modulus than steel, meaning that it takes much less force to bend and deform a given sample of wood.

- Q: How are steel coils inspected for surface finish after processing?

- Steel coils are inspected for surface finish after processing through various methods such as visual inspection, surface roughness measurement, and non-destructive testing techniques like magnetic particle inspection or eddy current testing. These inspections help ensure that the steel coils meet the required surface finish standards and are free from any defects or imperfections.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances vary depending on the specific industry and application. However, generally speaking, the typical coil thickness tolerances range from ±0.001 to ±0.005 inches (or ±0.025 to ±0.127 millimeters). These tolerances ensure that the coil meets the required specifications and can perform its intended function accurately.

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a series of processes that involve the transformation of raw materials into the final product. The manufacturing process begins with the extraction of iron ore, which is then smelted in a blast furnace to produce pig iron. The pig iron is further refined in a basic oxygen furnace to remove impurities and adjust the carbon content. Once the molten steel is obtained, it is continuously cast into large slabs or billets. These slabs are then rolled into thinner sheets or strips through a process called hot rolling. This involves passing the steel through a series of high-pressure rollers, which reduce the thickness and shape the material to the desired dimensions. During this process, the steel is also treated to improve its mechanical properties, such as strength and hardness. After hot rolling, the steel is pickled and cleaned to remove any scale or impurities on the surface. It is then cold rolled to further reduce the thickness and improve the surface finish. Cold rolling involves passing the steel through a set of rollers at room temperature, which increases its strength and dimensional accuracy. To form steel coils, the cold-rolled steel is typically wound tightly into a large coil shape. This is achieved by feeding the steel strip through a series of rollers that gradually wind it into a spiral. The coils are then typically annealed to relieve internal stresses and improve the material's formability. Finally, the steel coils are coated or treated, depending on their intended use. This can involve applying a protective coating, such as zinc or paint, to enhance corrosion resistance or providing a specific surface treatment for improved adhesion in subsequent processes. Overall, the manufacturing of steel coils is a complex process that involves several stages, including smelting, casting, hot rolling, cold rolling, coiling, and surface treatment. Each step contributes to the final product's quality and properties, ensuring that steel coils meet the required specifications for various industrial applications.

Send your message to us

Hot Sale Pre-Painted Galvanized (PPGI) Color Coated Steel/ Aluminized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords