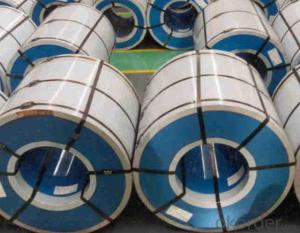

ppgi corrugated steel ,PPGL,PPGI sheet,prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS,DX51D | Grade: | DX51D | Thickness: | 0.17-1.2mm,0.2-1.2mm |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | ppgi |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Constuction,building material | Special Use: | High-strength Steel Plate | Width: | 600-1500mm(914/1000/1200/1220/1250mm),600mm-1250mm |

| Length: | coils | Zinc coating: | 60-275g/m2 | Technical: | cold rolled |

| coil ID: | 508mm | coil weight: | 3-5tons | Base steel: | galvanized steel coil,galvalume steel coil |

| Ral color: | available |

Packaging & Delivery

| Packaging Detail: | Seaworthy standard export packing |

| Delivery Detail: | within 30 days once we get the deposite or confirmed the L/C |

Specifications

1 thickness:0.17-1.2mm

2 width:600-1500mm(914/1000/1200/1220/1250mm)

3 Ral card colors available

4 Prime grade ppgi in stock

1 PPGI Description & Specification:

PPGI/PPGL is based on hot dipped galvanized /galvalume steel plate which is dealed with surface treatment( chemical degreasing and chemical conversion treatment )with one layer or several layers of organic coating,and then is baked and cured to finished products .Organic coating with a variety of different colors ,then ppgi also be calledcolor coated steel coil.GI and GL based PPGI/PPGL with both zinc layer and organic paint protection to make its service life 1.5 times longer than galvanized/galvalume steel coils.

PPGI/PPGL with light weight beautifal appearance and good corrosion resistance can be directly processed so it is widely used in light industry,househould

appliances,automotive and construction industry.For avrious types of industrial and civil construction industry,light steel keel,building level board,corrugated board,roller shutter doors. It was designed to protect steel surface from corrosion,extend its life,in the surface coating layer of Zinc and Color PE metal plate,making improvements to its surface characteristics of thin steel plate.

- Q: I heard on some shows that you can carbonise steel by heating it red hot then dropping it in black oil. i cant find this no where online, and the process for commercial carbon steel is totally different. can you really carbonise regular steel by heating it to red hot then dropping it in regular black oil. i saw it on mythbusters once. when the made carbon steel hammers to test if 2 hammers smashed together will shatter

- in the experience that your speaking a pair of folding pocket knife, i think of that it somewhat is somewhat six one way and a 0.5 dozen the different. i actually do choose stainless for my pocket knives. i don't choose to grease a knife to the degree i've got faith carbon demands, basically to then stick it my pocket to entice dirt to the knife and oil to my pants. i'm the impressive opposite on sheath knives nevertheless. i admire 1095 carbon steel, uncomplicated part sheath knives. i will thrash on them difficult, and that i rarely have considerable part issues. of course, I require them to be lined with some style of powder coat or the like, with the aid of fact they might rust, yet I do attempt and save them sparkling and dry whilst in the sheath, so as that they gained't pit the uncoated part. My motives for this sheath knife selection is multi-fold. First, those knives are only much less costly. i don't spend $80 money on a exterior sheath knife. i take advantage of the gadget too difficult to choose to spend extra. i don't basically like the extra classic stainless steels alongside with AUS-8, 420HC, and 440C (to not point out the HORRENDOUS 440A) with the aid of fact i've got faith that the all else being equivalent, a stainless blade will bend till now a carbon blade will harm. I additionally think of that carbon holds an part a minimum of besides, if not extra suited, than classic stainless, and it somewhat is plenty extra handy to hone. i don't understand plenty approximately those new laminates, different than the very difficult, yet not so difficult. they seem probably too brittle for my use. That, mixed with the actuality that they harm the bank, ability that I only is only not pondering them.

- Q: So I'm trying to decide which is better. I've always had aluminum on my 6 yr old tb gelding as I do hunters on him. He's never had steel on but I've recently moved and the shoer here is more expensive. So is aluminum really worth the extra cash to keep him light on his feet or is steel really not that much different?

- Shoes don't keep a horse light on their feet, good riding does. Aluminum bends really easily and will scratch and ruin quickly. That's why you have to have your horse shod more often with aluminum. Steel is worth it. They last longer. Personally though I think barefoot is the best option.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts as they serve as the primary raw material. The coils are unwound and fed into a machine that cuts and shapes the steel into bolts of the desired size and shape. The coils provide a continuous supply of high-quality steel, ensuring the consistency and strength of the bolts produced.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they are fed through a machine that measures and marks the desired length or shape. Next, a cutting tool or die is used to precisely cut the steel into the required dimensions. Finally, the cut pieces are inspected for quality and packaged for shipment.

- Q: How are steel coils used in the manufacturing of storage cabinets?

- Steel coils are used in the manufacturing of storage cabinets by being processed and formed into sheets, which are then cut, shaped, and welded together to create the structural framework and outer shell of the cabinets.

- Q: How are steel coils used in the manufacturing of steering columns?

- Steel coils are used in the manufacturing of steering columns as they provide the necessary strength and flexibility to withstand the forces and vibrations experienced during steering. The coils are shaped and formed into the desired design, allowing for the smooth and controlled movement of the steering column.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in shipbuilding materials as they provide a versatile and durable solution. They can be processed into various shapes and sizes, including plates, beams, and sections, which are essential components for constructing ships. The coils are often cut and shaped to fit specific design requirements, offering strength and structural integrity to the ship's framework. Additionally, the coils are utilized in the fabrication of various shipbuilding components, such as hulls, decks, bulkheads, and superstructures, ensuring the vessels' resilience and stability.

- Q: I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q: like, what can steel make?

- buildings bridges automobiles elevators railroads and railroad equipment appliances and many many more. Steel is used almost everywhere. reference: Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars (Despite growth in usage of aluminium, it is still the main material for car bodies.), steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.[66] Other common applications include shipbuilding, pipeline transport, mining, offshore construction, pipeline transport, aerospace, white goods (e.g. washing machines), heavy equipment (e.g. bulldozers), office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better known as rolled homogeneous armour in this role). .

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel strapping or bands. They are then placed onto pallets or into crates to protect them during transportation. Additionally, wooden or metal dunnage is often used to separate and stabilize the coils, ensuring they remain intact and in proper condition throughout the shipping process.

Send your message to us

ppgi corrugated steel ,PPGL,PPGI sheet,prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords