Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

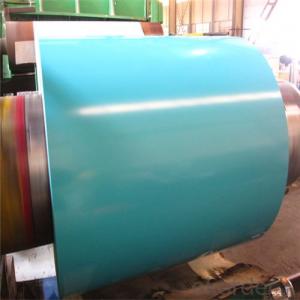

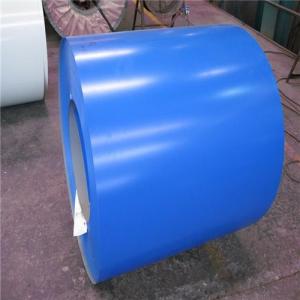

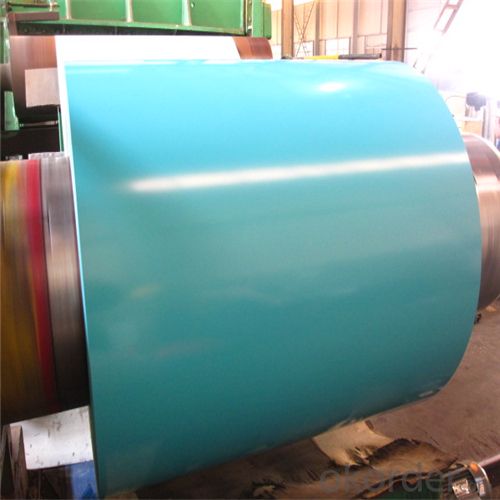

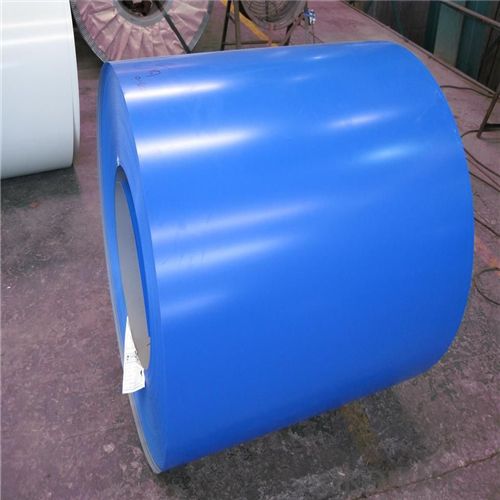

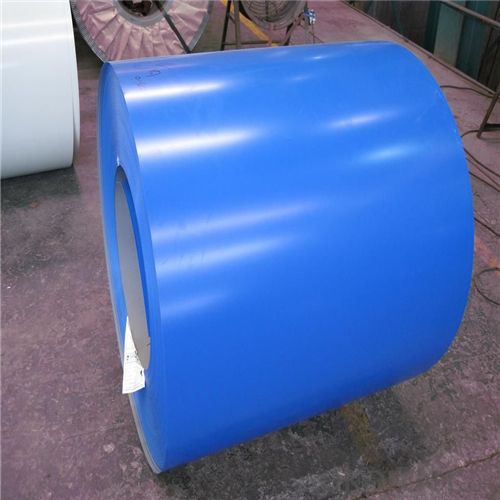

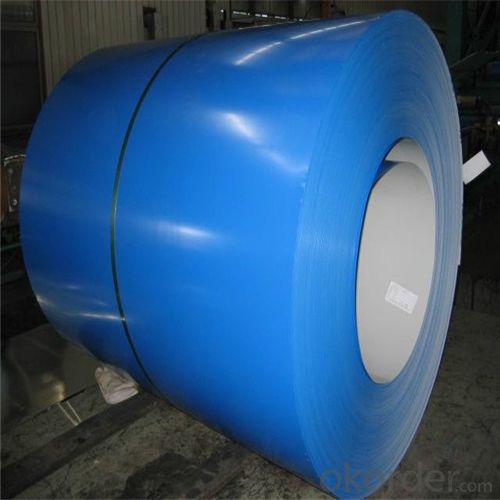

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. So we can give you commonly 50days.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are commonly used in the production of oil and gas machinery for various purposes. They are utilized in the manufacturing of pipes, tanks, and pressure vessels, providing structural strength and durability to withstand the harsh conditions of oil and gas operations. Additionally, steel coils are shaped and formed into components such as valves, fittings, and flanges, which are crucial for the proper functioning of the machinery. Overall, steel coils play a vital role in ensuring the reliability and efficiency of oil and gas machinery.

- Q: What is the average lifespan of a steel coil?

- The average lifespan of a steel coil can vary depending on several factors. These factors include the quality and type of steel used, the conditions in which the coil is stored or used, and the maintenance and care it receives. Generally, a well-maintained steel coil can last anywhere from 10 to 30 years. However, this is just an estimate and the actual lifespan can be shorter or longer depending on the aforementioned factors. For instance, if the steel coil is exposed to harsh environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be reduced. Regular maintenance and proper storage can significantly extend the lifespan of a steel coil. This includes ensuring that the coil is stored in a dry and protected environment, regularly inspecting and addressing any signs of corrosion or damage, and conducting routine cleaning and lubrication as needed. Ultimately, the average lifespan of a steel coil is dependent on various factors, and it is best to consult the manufacturer or industry experts for a more accurate estimate based on specific circumstances and conditions.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: What is the maximum load capacity for steel coil storage racks?

- The maximum load capacity for steel coil storage racks can vary depending on factors such as the design, dimensions, and construction materials of the rack. It is recommended to refer to the manufacturer's specifications or guidelines for accurate information on the maximum load capacity of a specific steel coil storage rack.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- Titanium Industrial Barbell

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they are shaped and cut into specific sizes to create the valve bodies and other components. The coils are then processed through various manufacturing techniques such as welding, machining, and forging to form the valve structure. This allows for the production of durable and reliable industrial valves that can withstand high pressure and temperature conditions in various industries.

- Q: What are the different methods of blanking steel coils?

- There are several methods used for blanking steel coils, which are: 1. Shearing: This method involves cutting the steel coil into the desired size and shape using a shear or a set of shears. Shearing is a common method used for blanking steel coils as it is a fast and cost-effective process. It is suitable for cutting thin to medium-thickness steel coils. 2. Laser cutting: Laser cutting is a precise and efficient method that uses a high-powered laser beam to cut through the steel coil. It is suitable for cutting complex shapes and thick steel coils. Laser cutting provides clean and accurate cuts, making it a preferred method for high-quality blanking. 3. Waterjet cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through the steel coil. This method is versatile and can cut through various materials, including steel, without generating heat. Waterjet cutting is suitable for cutting thick steel coils and is often used for intricate shapes and designs. 4. Stamping: Stamping is a method that involves pressing a die into the steel coil to cut out the desired shape. This process is commonly used for high-volume production as it can rapidly cut multiple pieces at once. Stamping is suitable for cutting simple shapes and is often combined with other processes like shearing or laser cutting for more complex shapes. 5. Plasma cutting: Plasma cutting uses a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Plasma cutting is known for its speed and versatility, making it a popular method for blanking steel coils. These methods of blanking steel coils provide different benefits depending on the requirements of the project, such as speed, precision, complexity of shapes, and material thickness. The choice of method depends on factors like cost, production volume, desired quality, and turnaround time.

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- steel case does not cause additional wear to the gun's chamber when compared to brass case. many tests has been done and precise measurements taken, this myth has been proven false. lacquer coating can cause issues because it can melt and cool, and cause jams. this is easily remedied with a chamber brush and some solvent.. However, steel jacket causes problems. Steel is harder than copper, it does not deform as easily so it causes more wear to the barrel as compared to copper or brass. The rate is around 10-25%, inreasing if you hoot rapidly instead of slowly. more shooting = hotter barrel = faster wear. It's the same with copper/brass jackets, but steel jacketed always wears more than softer metals. TulAmmo (or tula) is particular is so cheaply made they don't have enough copper/brass wash on the bullet to survive firing, after a few inches of travel it's steel on steel contact in the bore and it can ruin a gun barrel very quickly. But... there is one exception. if your gun comes with a chrome-lined bore that is standard for most AR's , shoot all the cheap junk you can buy. chrome-lined steel is 2X as hard as plain steel. crappy tula .223 will not cause more harm to a chrome-lined bore more than brass or copper jacketed bullets.

- Q: Can steel coils be used in outdoor applications?

- Indeed, outdoor applications can make use of steel coils. Steel, recognized for its resilience and robustness, proves to be ideal for various outdoor purposes. Commonly utilized in construction, automotive manufacturing, and transportation industries, steel coils exhibit resistance against adverse weather conditions like rain, snow, and UV exposure. Furthermore, to enhance their durability and prolong their lifespan, steel coils frequently undergo protective finishes such as galvanized or painted coatings. Ultimately, owing to their strength, durability, and ability to withstand environmental factors, steel coils emerge as a dependable and versatile choice for outdoor applications.

- Q: If rebar steel is welded together as opposed to 'tied' does it decrease the strength of the steel?

- If done correctly it should increase the tensile strength at least.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords