Pre-painted Aluzinc Steel Coil Used for Industry with Our Best Price and Service

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

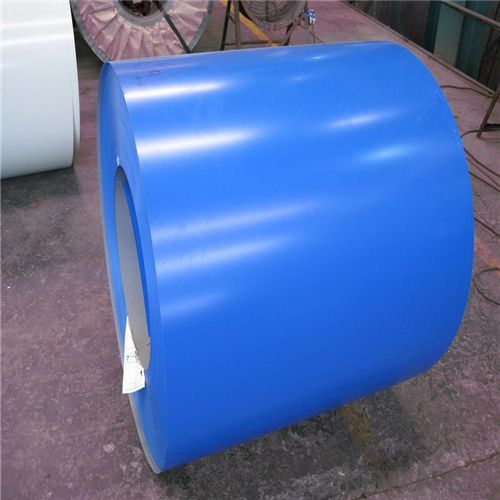

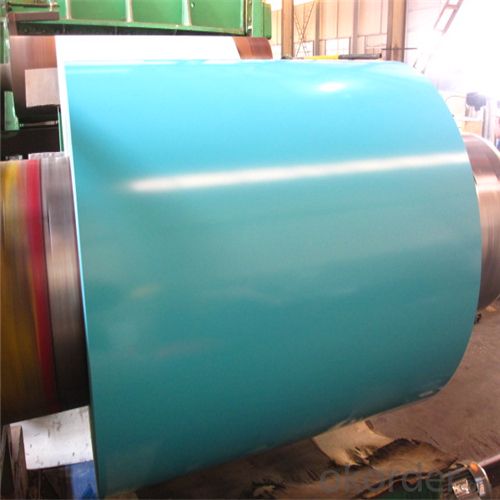

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Painting steel isthe product based on the metal sheet, of which surface is finally installed ofthe plastic film(PVC, PE) IN addition to being firstly covered with the coatingand printed ink in. The coated layer of painting steel plate consists of chemicaland filming layer, primer coated layer, pattern printed layer and surfacecoated layer. The top and back coating shall generally be the weatherproofpaint, as well can be the application of the paint with special capabilitiessuch as stain-resistant, self cleaning capability, high thermal resistance,antistatic capability, sterilizing capability, finger-print prevention and etc.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the safety precautions when working with steel coils?

- Some safety precautions when working with steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper lifting techniques to prevent musculoskeletal injuries, maintaining a clear and organized work area to avoid tripping hazards, using proper machinery and equipment to handle and transport the coils safely, and following established safety protocols and procedures. It is also important to receive proper training and supervision to handle steel coils effectively and minimize potential risks.

- Q: How are steel coils coated for specific applications?

- Steel coils are coated for specific applications through a process called coil coating. This involves applying a protective layer of paint, polymer, or other coatings onto the steel coils using methods like roll coating or spray coating. The coating is carefully selected based on the desired properties such as corrosion resistance, durability, or aesthetic appeal required for the specific application.

- Q: How are steel coils used in the manufacturing of agricultural equipment?

- Steel coils are used in the manufacturing of agricultural equipment as they serve as a raw material for various components such as frames, chassis, and structural supports. These coils are shaped, cut, and welded to form the necessary parts, providing strength, durability, and stability to the equipment.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on various factors such as the quality of the rack, the frequency and intensity of use, and proper maintenance. However, a well-maintained and durable steel coil storage rack can typically last for several decades.

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- i think steel

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils used in automotive part manufacturing can vary depending on the specific application and manufacturer. However, commonly used dimensions for steel coils in automotive part manufacturing range from 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can also vary, typically ranging from several meters to several hundred meters. It is important to note that these dimensions are not fixed and can be customized to meet the specific requirements of each automotive part being manufactured.

- Q: Why is the steel tape tape head not fixed?

- It makes sense to be irregular;You can see the standard ruler of steel roll head is a gap, when you take the time to object quantity, the head will indent the gap, so you measure is the size of the head from the head of steel;When you hook the object, the head will pull apart and you'll take the dimension from the end of the steel head.

- Q: where can you find carbon steel in los angeles?? what store?? preferabbly 01 carbon steel

- Try the internet. I'm sure the steel suppliers there know about this

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Our Best Price and Service

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords