Pre-painted Aluzinc Steel Coil PPGL in Good Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

inted Galvanized Steel Coil

1. Defination of Prepainted Galvanized Steel Coil

Pre-painted coils are produced by coating a layer of paint on the surface of cold rolled, galvanized or galvalumed coils. Aesthetic appeal and durability are the key festures of color coated steel coil. A wide selection of colors is available to the customer and paints designed to meet specific end use could be specified.

2. Applications of Prepainted Galvanized SteelCoil

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

3. Specifications of Prepainted Galvanized SteelCoil

Standard: ASTM;ASTM;JIS;GB

Grade: SGCC;(DX51D)

Thickness: 0.12-1.2mm

Width: 750-1250mm

Length: Coil or customer's requirements

Zinc Coating: 60-140g/m2

Painting : Top side from 15-25um; Bottom side from 5-10 um

Color : RAL numbers or customers' sample color

Application: building trade, electric apparatus, furniture and transport service

Production arts and crafts : Double coated double drying

Coil ID: 508mm

Coil Weight: 3-6 Ton

Type :coil

Packaging Detail: Fully seaworthy export packing with paper tube or as per customer's requirements

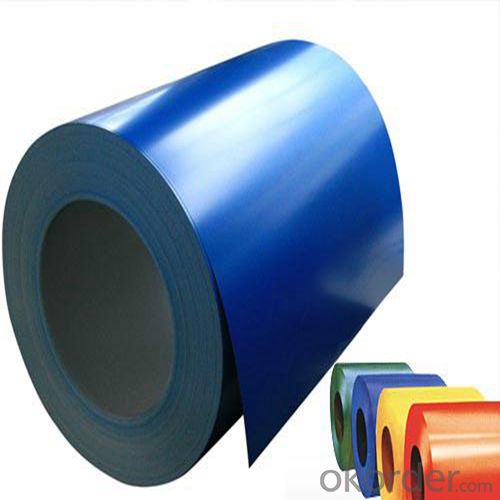

4. Prepainted Galvanized Steel Coil Images

5. Advantages of Our Prepainted Galvanized SteelCoil

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

6. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are stainless steel sheets suitable for structural applications?

- Stainless steel sheets, indeed, prove to be appropriate for structural applications. This material, known for its versatility and durability, boasts a remarkable strength-to-weight ratio, rendering it highly suitable for diverse structural purposes. Its exceptional corrosion resistance is particularly vital for structures subjected to severe environmental conditions or chemical exposure. Utilizing stainless steel sheets in the fabrication of bridges, buildings, and other structural elements ensures the attainment of necessary robustness and longevity. Moreover, stainless steel stands as a sustainable choice due to its complete recyclability, thereby further augmenting its appropriateness for structural applications.

- Q: Can stainless steel sheets be used for kitchen utensils?

- Yes, stainless steel sheets can be used for kitchen utensils. Stainless steel is a popular choice for kitchen utensils because it is durable, easy to clean, and resistant to rust and corrosion. Stainless steel sheets can be shaped and formed into various utensils such as spoons, forks, knives, spatulas, and more. Additionally, stainless steel is non-reactive, meaning it does not leach any harmful chemicals into food, making it a safe option for cooking and eating utensils. Overall, stainless steel sheets are a great material choice for kitchen utensils due to their strength, hygiene, and longevity.

- Q: Are stainless steel sheets resistant to erosion corrosion?

- Stainless steel sheets possess a high resistance to erosion corrosion, primarily because of the presence of chromium in the alloy. The chromium forms a protective layer of chromium oxide on the steel's surface, serving as a barrier against oxygen and moisture, thus safeguarding it from corrosion. Moreover, stainless steel sheets also exhibit resistance to erosion corrosion induced by various chemicals and acids. The composition of the alloy, typically containing elements like nickel and molybdenum, augments its ability to withstand corrosion in harsh environments. Consequently, stainless steel sheets find wide-ranging applications, including in industries such as chemical processing, oil and gas, and marine. Nevertheless, it is crucial to recognize that the resistance of stainless steel sheets to erosion corrosion may differ depending on the specific grade or alloy employed. Different grades possess varying levels of corrosion resistance, necessitating the selection of an appropriate grade based on the application's specific environmental conditions and requirements. Regular maintenance and proper handling can further extend the lifespan and uphold the corrosion resistance of stainless steel sheets.

- Q: Why do drill holes burn on stainless steel plates? What's the best way to drill them?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: What are the common uses of stainless steel sheets in the automotive industry?

- Stainless steel sheets are commonly used in the automotive industry for various purposes such as manufacturing body panels, exhaust systems, fuel tanks, and decorative trim. The corrosion-resistant properties of stainless steel make it an ideal material for these applications, providing durability and aesthetic appeal to vehicles.

- Q: What is the difference between hot rolled and cold rolled stainless steel sheets?

- The main difference between hot rolled and cold rolled stainless steel sheets lies in the manufacturing process. Hot rolled stainless steel sheets are produced by heating a stainless steel slab above its recrystallization temperature and then rolling it through a series of rollers to achieve the desired thickness. This process results in a rougher surface finish and can sometimes lead to a slight curvature in the sheets. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then passing them through a set of rollers at room temperature. This process creates sheets with a smoother surface finish and precise dimensions. Cold rolling also increases the strength and hardness of the stainless steel. In summary, hot rolled stainless steel sheets have a rougher surface finish and may exhibit slight curvatures, while cold rolled stainless steel sheets have a smoother surface finish and are more precise in their dimensions.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Yes, stainless steel sheets can be used for outdoor signage or billboards. Stainless steel is highly durable, weather-resistant, and corrosion-resistant, making it an excellent material choice for outdoor applications. It can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. Additionally, stainless steel sheets can be easily fabricated and customized to create visually appealing and long-lasting outdoor signage or billboards.

- Q: How do you prevent chloride-induced corrosion in stainless steel sheets?

- There are various steps that can be taken to prevent corrosion in stainless steel sheets caused by chloride. These include: 1. Selecting the appropriate stainless steel grade that is resistant to chloride corrosion. Grades like 316 or 317 are particularly effective in resisting chloride attack. 2. Enhancing the resistance to chloride-induced corrosion by applying a passivation treatment to the stainless steel sheets. This treatment eliminates any surface iron contamination that might have occurred during fabrication and restores the protective oxide layer. 3. Ensuring proper cleaning of the stainless steel sheets on a regular basis to eliminate any chloride-containing contaminants that might have accumulated on the surface. It is important to maintain a clean surface as chloride ions can accumulate from sources like saltwater or cleaning products. 4. Minimizing contact with substances that contain chloride to significantly reduce the risk of corrosion. This involves avoiding direct contact with saltwater, cleaning agents that contain chloride, as well as chloride-rich environments such as swimming pools or coastal areas. 5. Taking design considerations into account in environments where chloride exposure is expected. This can involve using protective coatings, minimizing crevices or gaps where chlorides can accumulate, and ensuring proper drainage to prevent stagnant conditions. 6. Regularly inspecting and maintaining the stainless steel sheets to identify and address any potential corrosion issues before they worsen. This may include repairing surface damage, reapplying passivation treatments if necessary, and keeping the surface clean. By following these preventive measures, the risk of chloride-induced corrosion in stainless steel sheets can be significantly reduced, ensuring their long-term durability and performance.

- Q: Can stainless steel sheets be used for architectural columns?

- Yes, stainless steel sheets can be used for architectural columns. Stainless steel is a versatile and durable material that can withstand various weather conditions and provide a modern and sleek aesthetic to architectural designs. It is commonly used in architectural applications, including columns, due to its corrosion resistance, strength, and aesthetic appeal.

- Q: Are stainless steel sheets suitable for industrial kitchens?

- Yes, stainless steel sheets are highly suitable for industrial kitchens. Stainless steel is a popular choice for commercial kitchens due to its numerous advantageous properties. Firstly, stainless steel is highly resistant to corrosion and rust, making it ideal for environments with high humidity and exposure to water and chemicals typically found in industrial kitchens. This resistance also ensures that stainless steel sheets are long-lasting and durable, making them a cost-effective choice in the long run. Secondly, stainless steel is easy to clean and maintain, which is crucial in a busy kitchen environment where hygiene is of utmost importance. Its smooth and non-porous surface prevents the accumulation of dirt, grease, and bacteria, making it a hygienic choice and reducing the risk of cross-contamination. Furthermore, stainless steel sheets are heat resistant, making them suitable for use in industrial kitchens where high temperatures are involved, such as near stoves, ovens, or grills. Stainless steel is also resistant to staining and is not affected by acidic or alkaline substances commonly used in cooking and cleaning processes. In addition to its functional properties, stainless steel sheets are aesthetically pleasing and can enhance the overall appearance of an industrial kitchen. They provide a sleek and modern look that can easily fit into various design styles. Overall, stainless steel sheets are a highly suitable choice for industrial kitchens due to their corrosion resistance, durability, ease of cleaning, heat resistance, and hygienic properties. They offer a practical and visually appealing solution that meets the demands of a busy commercial kitchen environment.

Send your message to us

Pre-painted Aluzinc Steel Coil PPGL in Good Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords