Pre-Painted Aluzinc Steel Coils/ Sheets /PPGI with Super Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications

Prepaint Aluzinc Steel Coil

.Thicknee:0.10-1.20mm

.Width:600-1250mm

.Good quality and service

.Standard Export seaworthy

2. PREPAINTED GALVANIZED STEEL

. Prepainted Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

. The base metals for Prepainted Steel Coil consist of cold rolled, galvanized The finish coats of Prepainted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3.High Quality Pre-Painted Aluzinc Steel Coil

Product Description

| Commodity | Prepainted Galvalume Steel Coil/Sheet | ||||||||

| Standard | Q/BQB445 JISG3322 EN10327 | ||||||||

| Grade | TDC51D+AZ/TDC52D+AZ/TS250GD+AZ/TS300GS+AZ/TS350+AZ/TS350GD+AZ/TS550GD+AZ/CGLCC/ | ||||||||

| CGLCD/CGLC490/CGLC570/DX51D+AZ/DX52D+AZ/S250GB+AZ/S300GD+AZ/S350GD+AZ/S550+AZ | |||||||||

| Thicknees | 0.16-1.2 mm | Width | 600-1250mm | ||||||

| Zinc Coating | AZ30-AZ150g/m2 | Coil Weight(Min or Max) | 3-8 tons | ||||||

| Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | ||||||

| Color | Ral Color | As Customers' requirement | |||||||

| Surface Finish | Normal Coated | Embossed | Printed | ||||||

| Category Of Finish Coating | High-durability Polyester | Silicon Modified Polyesters | |||||||

| Polyvinylidene Fluoride | Polyester | ||||||||

| Anti-static | Easy-Cleaning | ||||||||

| Coating Type | Top Surface | Bottom Surface | |||||||

| Double Coated | Double Coated | ||||||||

| Double Coated | Single Coated | ||||||||

| Coating Thickness | Top Surface: | Back Surface: | |||||||

| Coating Structure | Primer | Finish Coating | |||||||

| Epoxy Primer | Polyester | ||||||||

| Polyester Primer | Silicon Modified Polyesters | ||||||||

| Water-soluble Acrylic Acid Primer | High-durability Polyester | ||||||||

| Polyurethane Primer | Polyvinylidene Fluoride | ||||||||

| Method of Test | <1>Acid/Alkaline-Resistance Test | <2>Test of Resistance to Neutral Mist | |||||||

| <3>Air Exposure Test | |||||||||

| Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | |||||||

Application | Construction | Outside | workshop,agricultural,warehouse,corrugated roof,wall,etc | ||||||

| Inside | doo,doorcase,light steel roof structure,vent gutter,etc | ||||||||

| Electial Appliance | refrigetator.washer,switch cabinet,etc | ||||||||

| Furniture | central heating slice,lampshade,etc | ||||||||

| Carrying Trade | clapboard,container,etc | ||||||||

| Others | writing panel,garbage can,timekeeper,etc | ||||||||

Applications

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

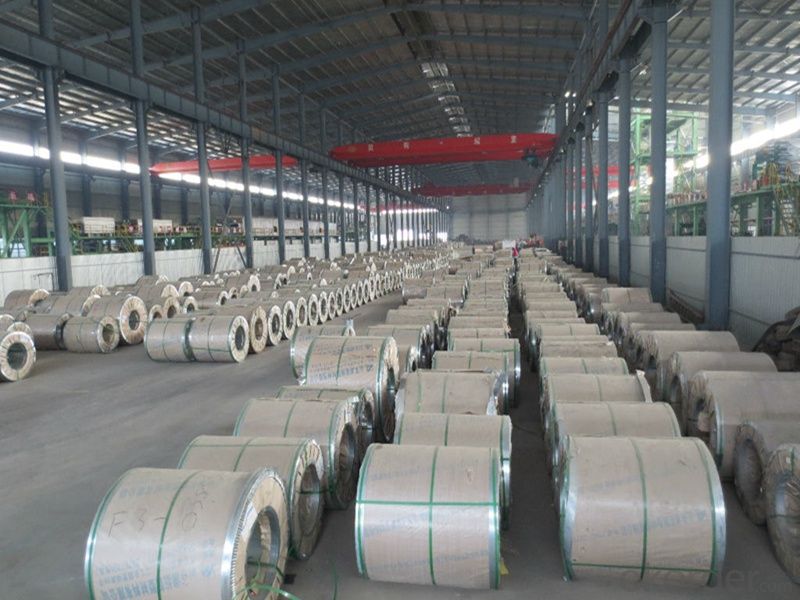

4. Pictures

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of color steel coils,is one of the large-scale professional investment steel production bases in China. Annually more than 8000 tons Precision Steel coils to be exported for more than 60 countries.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 10 to 15 working days can be served.

- Q: So, i recently bought the game red steel 2 and i beat it, it was an amazing game! although since i had never played the first one ( i never knew about it actually) i had alot of questions like, why was he banished, where is his actual master, etc so i searched up on Youtube, red steel 1 to figure it all out and the games look nothing alike!! i mean the first one is like nothing but guns and the characters arnt the same ( well at least i dont think so) could someone explain why?

- Red Steel 2 isn't really a sequel to Red Steel 1 in a normal sense. The reason the new one is named Red Steel 2 is because of the Sword + Gun combat, which was also in the first game (even though the sword part wasn't good in the first one). Other than that, I'm guessing Ubisoft just wanted to take a different, less realistic approach with it.

- Q: What are the common methods of packaging steel coils for transportation?

- The common methods of packaging steel coils for transportation include strapping, wrapping, and using wooden or steel cradles. Strapping involves securing the coils with metal or polyester bands, while wrapping involves using stretch film or shrink wrap to protect the coils from moisture and damage. Wooden or steel cradles are used to stack and secure multiple coils together, ensuring stability during transportation.

- Q: I own a crappy steel string acoustic and a very nice electric guitar.I have saved up to buy a new acoustic but I cannot decide to just invest in a better steel string or explore around with a nylon string. From others experience, will I get my fill of satisfaction of playing on a nylon, or should I stick to a steel string?

- Really?! I think you would be more satisfied with a harmonica. And that is because I know you better than you know yourself. But, if you like steel, go for a 12-string.

- Q: How are steel coils used in the manufacturing of cables?

- Steel coils are used in the manufacturing of cables as they provide strength and support to the cable structure. The steel coils are typically used as armor or reinforcement, helping to protect the cables from external elements and maintain their structural integrity.

- Q: How are steel coils used in the production of aerospace structures?

- Various methods are employed in the production of aerospace structures, with steel coils being a key component. Aircraft frames and components are commonly manufactured using steel coils. These coils are processed through a series of operations, such as cutting, bending, and welding, to create the necessary structural members of an aircraft, including fuselage sections, wing spars, and landing gear. The preference for steel coils in aerospace applications is due to their exceptional strength and durability. They are capable of withstanding the immense forces and stresses experienced during flight and landing. By utilizing steel coils, aerospace structures are able to maintain the required structural integrity, even in harsh operating conditions. Moreover, steel coils are also utilized in the production of aerospace fasteners and connectors. These components are crucial for securely holding various parts and structures together. Bolts, screws, and rivets, which are essential for assembling different sections of an aircraft, are commonly manufactured using steel coil materials. The strength and reliability of steel coils make them ideal for fastening applications, ensuring the secure connection of aerospace structures. Additionally, steel coils find application in the production of aerospace equipment and machinery. Heavy machinery and specialized equipment are integral to aerospace manufacturing processes. Steel coils are frequently used in the construction of these machines, as they provide robust and sturdy frameworks. Tooling, jigs, fixtures, and molds, which are necessary for producing aerospace structures with precision and accuracy, often incorporate steel coils. In conclusion, steel coils play a vital role in the production of aerospace structures. They are utilized as raw materials for manufacturing aircraft frames and components, fasteners and connectors, as well as aerospace equipment and machinery. The strength, durability, and reliability of steel coils make them indispensable in the aerospace industry, ensuring the safety and integrity of aerospace structures.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- Since2003, India has been the largest sponge iron producer in the world. In 2005, out of total global production of 56.05 mt of sponge iron, India produced around 11.1 mt (19.8%). In line with production target of 110 mt of steel (National Steel Policy) by FY20, many steel producers have announced their capacity expansion plans by signing MOUs with various state governments like Chattisgarh, Orissa and Jharkhand. The steel producers are expected to add around 8 mt of capacity by FY 08. CARE estimates that during 2006-09, demand for steel in the domestic market would grow at a CAGR of 8.4%. HR steel because of its widespread applicability is expected to grow at a CAGR of 17.5%. During this period, major demand drivers would be Consumer durables, Automobiles and Construction. Domestically, steel prices of flat products follow the international trend. Globally, steel prices are expected to firm up with continued growth in steel consumption. Further, the winds of consolidation have gathered pace with Arcelor-Mittal merger and latest acquisition of Corus by Tata Steel. The Indian steel industry has announced huge capacity expansions. With commissioning of these capacities demand-capacity ratio is expected to decline in FY 09 due to excess capacity. Will this lead to a drop in prices with commissioning of these capacities? With China and India becoming the focus of major global steel companies, will the consolidation of steel industry in these countries continue? For comprehensive analysis and CARE’s future outlook on the sector, please refer to the exhaustive report on the Indian Steel Industry by CARE Research.

- Q: I Don't have a Oxy act. torch but can Get a Propane one. The finished part(s) are .375 x .550 x .185

- Hardening steel is done by quenching. Quenching is accomplished by heating the element and then rapidly cooling it. In metallurgy, it is most commonly used to harden steel by introducing martensite, in which case the steel must be rapidly cooled through its eutectoid point. For 12L14 steel, the eutectoid point is approximately 2800 degrees F. Unfortunately, a propane torch has the capacity to reach tempuratures up to 1995 degrees... 12L14 is rather difficult to harden even with the correct tools. Good luck!

- Q: What are the different methods of coil end welding for steel coils?

- There are several different methods of coil end welding for steel coils, which include resistance welding, laser welding, and electric arc welding.

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific type of steel and its intended application. However, generally speaking, steel coils can withstand temperatures ranging from around 500 to 1200 degrees Celsius (932 to 2192 degrees Fahrenheit).

- Q: A steel rod AISI 1040 has the ultimate tensile strength Sut of 113 kpsi. Determine the rotating bending specimen's endurance limit S'e at 10 to the 6th cycles.

- It okorder

Send your message to us

Pre-Painted Aluzinc Steel Coils/ Sheets /PPGI with Super Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords