Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

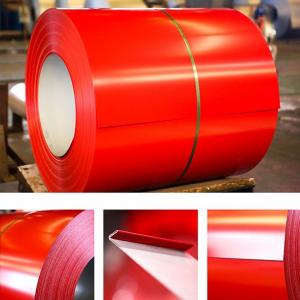

Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL

1.Structure of Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL

Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL is one kinds of building material on construction. PPGL is made by the processes of chemical preconditioning, first coating, precision coating and so on through a continuous rapid unit internationally in recent three decades. Its quality is more uniform and stable than the one whose surface of the formed metal is coated single or brushed one.

2.Main Features of Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL.

1) Rust-proof

2) Water-proof

3)Durable using

3. Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL Images

4. Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL Specification

1)Based raw material: Hot rolled steel coils or Cold rolled steel coils

2) Thickness

3) Width

4)Coating mass

5) Spangle

6)Surface treatment

7)Coil inner diameter

8)Painting color

9)Painting kind

10)Paiting thickness

5.FAQ of Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How is the packaging and delivery?

Exporting Package with the steel material cover and the delivery term is based on the project.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- Just compare the densities. The density of diamond is about 3.5g/mL. While there are different types of steel with different densities, steel is mostly iron, so the density of iron is a good approximation. Iron has a density of 7.87g/mL. Steel is over twice as dense as diamond, so the diamond sword would be lighter.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: How are steel coils protected against bending and deformation?

- Steel coils are protected against bending and deformation through the use of robust packaging materials, such as wooden crates or steel strapping, which provide structural support and prevent any external pressure from causing damage. Additionally, steel coils may be stored and transported in specialized racks or containers designed to evenly distribute weight and minimize the risk of bending or deformation.

- Q: What are the different methods of slitting steel coils?

- There are several different methods of slitting steel coils, each with its own advantages and limitations. Some of the most common methods include: 1. Rotary Shear Slitting: This method involves using rotating knives to cut the steel coil into narrower strips. It is a versatile and efficient method that allows for high-speed production and precise slitting. Rotary shear slitting is commonly used for thinner gauge materials. 2. Looping Pit Slitting: In this method, the steel coil passes through a looping pit where it is guided and tensioned before being slit. It is suitable for thicker gauge materials and provides good edge quality. Looping pit slitting allows for higher coil speeds and can handle heavier coils. 3. Drag Slitting: This method involves dragging the steel coil over a stationary blade or set of blades to perform the slitting. It is particularly useful for materials that are difficult to slit, such as high-strength steels. Drag slitting provides excellent edge quality and is often used for precision slitting applications. 4. Crush Slitting: Crush slitting involves applying pressure to the steel coil to crush and separate it into narrower strips. It is a cost-effective method suitable for lower gauge materials. However, it may result in slightly rougher edge quality compared to other methods. 5. Laser Slitting: Laser slitting utilizes a focused laser beam to cut through the steel coil. It is a highly precise method that offers excellent edge quality and minimal distortion. Laser slitting is commonly used for high-value and specialty materials. Each method has its own advantages and is suitable for specific applications and material types. The choice of slitting method depends on factors such as material thickness, desired edge quality, production speed requirements, and budget.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q: How are steel coils used in the manufacturing of aerospace components?

- Steel coils are used in the manufacturing of aerospace components as they provide a reliable and durable material for various applications. The coils are typically cut and formed into different shapes to create components like structural supports, brackets, and fasteners. These components play crucial roles in the construction and assembly of aerospace systems, ensuring strength, stability, and safety in the final products.

- Q: What are the different methods of surface treatment for steel coils?

- There are several methods of surface treatment for steel coils, including hot-dip galvanizing, electro-galvanizing, chromating, and painting.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: What are the different steel coil packaging methods?

- There are several different steel coil packaging methods, including using steel strapping or banding to secure the coils, using plastic or metal end caps to protect the edges of the coils, and using wooden or steel pallets to stack and transport the coils. Additionally, some steel coils may be wrapped in protective film or paper to prevent damage during shipping and storage.

- Q: How are steel coils used in the production of shipping containers?

- Steel coils are used in the production of shipping containers as they are formed and shaped into the required structure and size. The coils are unrolled and cut into sheets, which are then molded and welded to create the walls, roof, and floor of the container. This process ensures the container's strength, durability, and ability to withstand harsh shipping conditions.

Send your message to us

Prepainted Hot Dipped Aluzinc Steel Sheets In Coils PPGL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords