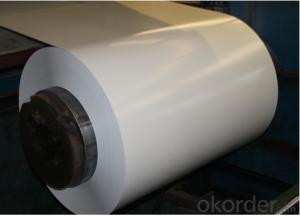

Pre-Painted Aluzinc Steel Coil for Sandwich Wall Thinkness 2mm Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Specifications of Pre Painted Galvanized Steel Coil:

1) Capacity: More than 20, 000 tons per month for PPGI coil product manufacture

2) Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

3) Grade: SGCC CGCC, DX51D, TDC51D, ASTM A653 CS TYPE, S280GD, S350GD, G550

4) Thickness: 0.15mm-1.5mm

5) Zinc coating weight: Z60-275G/M2, G30-G90

Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

6) Width: 600mm-1250mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm or according to the customer's request

7) Coil ID: 508mm-610mm

8) Coil Weight: 3-6mt, or according to the customer's request

9) Color: RAL, or customer sample color

RAL9016, RAL9002, RAL5015, RAL5002, RAL3000, RAL3020, RAL3009, RAL6005, RAL8017 etc.

10) Color coating type: PE, PVDF, SMP, HDP, etc.

Regular Polyester, Silicon Modified Polyester, Polyvinylidene Floride, PVDF, Super Low Gloss Polyester

11) Surface protection: PVC film protected according to customer requested

12) Min trial order: 25 tons for 1X20' per delivery

PPGI Manufacture

ThicknessWidth LengthColor Coating type

0.2mm-1.5mm600mm-1250mmAs your requestRALPE, PVDF, SMP, HDP, etc.

Coating Chief Feature

ItemThicknessTypeFeature

Laminated film50μ MPolyethyleneProtecting from scratchs and contamination

(option)

Top coat20μ MPolyester FluorineChemical resistance and formability

Primer coat5μ MPolyesterWorkability, corrosion resistance and adhesion to the primer coating

Chemical treatment1μ MChromateGood adhesion and corrosion resistance

Substrate0.2mm-1.2mmGI. GL, ALGI. GL, AL

Back coat5± 2μ MEpoxyCorrosion resistance and adhesion to the substrate

Characteristics:

20 years outdoor liability approved, Corrosion protection, Long life-time for coated color

APPLICATION:

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

Yogic has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc...

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

FAQ

What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as a primary material for manufacturing the connector's housing or casing. The steel coils are typically shaped, cut, and formed into the desired shape and size before being further processed and assembled with other components to create the final electrical connector product.

- Q: What are the dimensions of steel coils used in the construction materials industry?

- The dimensions of steel coils utilized in the construction materials industry may differ based on specific requirements and applications. Nevertheless, there exist some commonly employed dimensions. In this industry, steel coils usually possess a width that spans from 600mm to 2,000mm, with the most frequently observed widths being 1,000mm and 1,200mm. The thickness of these coils can fluctuate between 0.4mm and 2.5mm, with the most commonly adopted thicknesses ranging between 0.6mm and 1.2mm. The inner diameter of the coil, commonly referred to as the core size, can vary from 508mm to 610mm, with 610mm being the predominant core size. Moreover, the weight of these coils can also differ, with typical weights ranging from 3 to 15 tons. It is important to emphasize that these dimensions might alter depending on specific project requirements and can be tailored to suit the demands of a particular construction project.

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils used in the agricultural structure industry can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in this industry range from 0.5mm to 3mm in thickness, and from 600mm to 1500mm in width. The length of the coils can also vary, but typically ranges from 1000mm to 3000mm. These dimensions allow for flexibility in the construction of agricultural structures such as barns, sheds, and storage facilities, while providing sufficient strength and durability. It is important to note that specific dimensions may vary depending on the manufacturer and the specific needs of the agricultural project.

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems as they are an essential raw material for manufacturing various components, such as chassis, frames, body panels, and suspension systems. These coils are shaped, cut, and welded to create the structural framework and body of vehicles, ensuring strength, durability, and safety. Additionally, steel coils are also used in the production of railway tracks and infrastructure, further supporting the transportation sector.

- Q: How are steel coils used in the production of electrical transmission poles?

- Steel coils are used in the production of electrical transmission poles as the primary material for constructing the pole itself. The steel coils are typically cut and shaped into the desired dimensions, then welded together to form the pole structure. This provides strength, durability, and stability to withstand the load and environmental conditions associated with electrical transmission lines.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into rails. These coils are transformed into long, straight sections of steel that form the main structure of the track. This process involves cutting, bending, and welding the coils to create the desired rail shape and dimensions. The resulting rails are then installed on rail beds to provide a durable and reliable foundation for trains to run on.

- Q: How are steel coils used in the production of metal ductwork?

- Steel coils are an essential component in the production of metal ductwork. These coils, typically made from high-quality steel, serve as the primary raw material for manufacturing ductwork. The process begins with the unwinding of the steel coil, which is then cut into specific lengths according to the required dimensions of the ductwork. These lengths are then shaped into the desired form using specialized machinery, such as roll formers or bending machines. The steel coils provide the necessary strength and durability to the ductwork, ensuring that it can withstand the pressure and environmental conditions it may encounter in its operational life. The coil's composition also allows for easy fabrication and customization, enabling manufacturers to create ductwork of various shapes and sizes to meet specific project requirements. Furthermore, the inherent properties of steel, such as its resistance to corrosion and fire, make it an ideal material for ductwork. Steel coils can be coated with protective layers, such as galvanized or stainless steel finishes, to enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional even in harsh environments or in the presence of corrosive substances. In summary, steel coils play a crucial role in the production of metal ductwork by providing the necessary raw material for fabrication. Their strength, durability, and customization capabilities make steel coils an indispensable component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

- Q: How are steel coils inspected for straightness using laser alignment?

- The straightness of steel coils is examined using laser alignment technology in a precise and automated manner. This technology offers a non-contact approach to measuring the straightness of steel coils with high accuracy and efficiency. To begin with, a conveyor system is utilized to move the steel coil through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for measuring straightness. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a perfectly straight and parallel laser beam for alignment purposes. On the opposite side of the coil, the receiver unit captures the laser beam and analyzes its position. As the coil progresses through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This is accomplished by analyzing the position of the laser beam at multiple points along the width of the coil. The laser alignment system is connected to a computerized control system that processes the data obtained from the receiver unit. The control system performs intricate calculations to determine the straightness of the coil based on the position of the laser beam. Any variations or deviations from the desired straight line are recorded and thoroughly examined by the control system. The inspection data can be viewed in real-time, enabling operators to monitor the straightness of the steel coil during the inspection process. The use of laser alignment technology for steel coil inspection offers numerous benefits. It provides highly precise measurements, ensuring that even slight deviations from straightness are detected. Furthermore, the non-contact nature of laser alignment eliminates the need for physical contact with the coil, thus reducing the risk of damage or contamination. Additionally, the automated process saves time and enhances efficiency compared to manual inspection methods. In conclusion, laser alignment technology is a dependable and efficient method for inspecting the straightness of steel coils. It guarantees that only coils meeting the required straightness criteria are approved, thereby contributing to the quality control of steel manufacturing processes.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide the raw material for forming the enclosures' outer shells and structural components. The steel coils are processed and shaped through various techniques such as cutting, bending, and welding, to create the desired size and shape of the enclosure. The steel's strength and durability make it an ideal material choice for ensuring the enclosures can protect electrical equipment from environmental factors and provide safety for users.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- Just google steel arch building, you will get plenty of selection , pictures, prices and designs

Send your message to us

Pre-Painted Aluzinc Steel Coil for Sandwich Wall Thinkness 2mm Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords