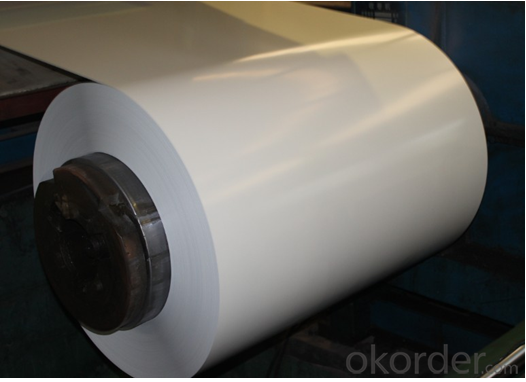

Pre-Painted Aluzinc Steel Coil for Sandwich Wall Thinkness 1.2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

PPGI:

1, Introduction: Color coated steel coils(sheets), i. e. PPGI, also called prepainted steel coils(sheets), are made of galvanized steel coils(sheets) with polymer coatings as surface. It's a new enclosure material and building board with characteristics of light-weighted, heat preserved&insulated, easily installed with bright colors.

2, Production Process: Pretreatment(Degreasing)_Drying_Chromating_Paint Basic Oil_Cooling_Drying_Color Coating_Cooling_Film-covering_Rolling Up

3, Characteristics:

Good at corrosion resistence. Besides zinc coating of the basic plate of galvanized steel sheet, the color coating as the surface has double lifetime to ensure better anticorrosion effect.

with excellent cold bending molded manufacturablity, PPGI products can be processed or directly used as final product. As being light-weighted and conveniently transported, they're widly used to replace wood to save energy.

There're thousands of colors can be chosen as per different application. Any color plays well in decoration.

No pollution with high recycling rate, PPGI coils and sheets are strongly recommended as enviroment-friendly products by the government.

4, Appliance: Thanks to the above characteristics, color coated steel coils and sheets are widly used in construction, furniture industry, transportation industry, ect.

5, eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized.

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

FAQ

What is the validity of your quotation?

Normally 24 hours.

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- In most applications, you do not want to make the graphite fiber composite object the same size as the steel object. You want it to have the same strength. So... the benefit of using the composite is not just the difference in density. What you really want to compare is the specific strength and you can define this slightly differently depending on your application. As a simple example, suppose you need to hang a weight of 100 pounds from a beam with a bar (so the load is pure tension) and not have the weight permanently stretch the bar (so stress in the bar is less than the yield stress). You can calculate the cross sectional area of steel and compare that to the cross sectional area of the graphite fiber composite required. If your application is more complicated, say it has to support the load and flex up to 10 degrees and survive some impact loading and operate at a max temperature of 200C, then you have more homework to do to select the best material. And... if you are not rich enough so that money is no object, you also need to consider the cost.

- Q: How do steel coils contribute to the strength and durability of structures?

- Steel coils contribute to the strength and durability of structures by providing a high tensile strength and resistance to deformation. When used in construction, steel coils can be formed into various shapes and sizes to reinforce structural components like beams, columns, and foundations. This reinforcement enhances the structural integrity, preventing the structure from collapsing under heavy loads or adverse conditions. Additionally, steel coils have excellent corrosion resistance, which ensures that the structure remains durable and long-lasting, even in harsh environments.

- Q: Can you reload spent casings if they are steel?

- Let me break it down for you. 1) There are two kinds of priming in current use these days -- you cannot tell from the outside which primer it is...only by looking inside the casing. If the casing has a single center primer hole, it is Boxer primed. If the casing has multiple primer holes, none of which is center, it is Berdan primed. Berdan and Boxer are the names of men who designed the priming systems.

- Q: What are the cost implications of using steel coils in manufacturing?

- The cost implications of incorporating steel coils into the manufacturing process can vary based on multiple factors. To begin with, the overall manufacturing expenses can be significantly affected by the cost of purchasing the steel coils themselves. Steel prices are influenced by various factors, including supply and demand, global market conditions, and any tariffs or trade regulations in place. Fluctuations in steel prices directly impact the cost of acquiring steel coils, which, in turn, affects the overall manufacturing cost. Furthermore, transportation costs can be influenced by the size and weight of the steel coils. Due to their heaviness and bulkiness, steel coils often incur higher shipping expenses as they require increased transportation resources. Additionally, shipping costs can be influenced by the distance between the steel supplier and the manufacturing facility. Moreover, the manufacturing costs can be influenced by the processing and transformation of steel coils into finished products. Depending on the desired end product, additional steps such as cutting, shaping, welding, or coating may be necessary. These supplementary processes require specialized machinery, skilled labor, and extra materials, all of which contribute to the overall manufacturing expenses. Considering the quality and durability of the steel coils is also essential. Although using high-quality steel coils may initially result in higher costs, it can lead to long-term savings by reducing the need for repairs or replacements. Furthermore, it is crucial to consider any regulatory or compliance requirements associated with the use of steel coils in manufacturing. Certain industries may have specific standards or certifications that need to be met, resulting in additional costs for testing, inspections, or compliance procedures. Lastly, it is important to acknowledge the potential cost savings that can be achieved through the utilization of steel coils in terms of efficiency and productivity. Steel coils are often preferred in manufacturing due to their strength, durability, and ease of fabrication. These characteristics can lead to improved production processes, reduced waste, and higher overall output, which can offset the initial cost of using steel coils. In conclusion, the cost implications of using steel coils in manufacturing are influenced by several factors, including steel prices, transportation costs, additional processing requirements, quality considerations, regulatory compliance, and potential productivity gains. A careful analysis and consideration of these factors are crucial for understanding the overall cost impact on manufacturing operations.

- Q: Ok, I need two negative facts about steel wheels and two for aluminum wheels. im designing a wheel for a project in design and draw for production class. Also if you find a web site that you got the info from plz refrence it i need to write down the source of the info, but if you can't its ok. Thanks

- Negative facts for steel wheels: (1) Not as many style choices as aluminum. (2) Rust easily even when painted or powder coated, due to rock chips. (3) Heaver than aluminum, as far as fuel economy. Negative facts for aluminum wheels: (1) More sensitive to proper torquing of lug nuts. IE torque must be checked more often. (2) Susceptible to impact damage from road hazards much more than steel. (3) Need constant attention to prevent oxidation. Are these what you are looking for? I hope so. Wingman

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts as they serve as the primary raw material. The coils are unwound and fed into a machine that cuts and shapes the steel into bolts of the desired size and shape. The coils provide a continuous supply of high-quality steel, ensuring the consistency and strength of the bolts produced.

- Q: hey... i don't need to change my strings, but i found a set of Bronze acoustic guitar strings by pure tone... i have a few questions on them:can i put them on a steel string guitar? i know i can't put nylon strings on... but i don't see why i can't put bronzethey are light gauze... i have no idea what my current gauze is, but i play in Dropped D tuning... so would the E/D string (6th) be too loose? finally, can you get strings designed to be played in Drop D?any help is apprechiated :D

- I don't see why not. Put them on and try it out.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q: What is the maximum weight capacity for a steel coil lifting device?

- The maximum weight capacity for a steel coil lifting device depends on various factors such as the design, size, and specifications of the specific lifting device. It is crucial to refer to the manufacturer's guidelines or consult with a qualified engineer to determine the exact weight capacity for a particular steel coil lifting device.

- Q: With the Reduced weight of steel,wouldn't the projectile be at a much higher velocity when fired causing more damage?I mean l couldn't steel be worked to seal the bore,not damage the rifling and still cheap enough to mass produce,and be light enough to carry much more ammo.

- The bullet needs to be a bit malleable to conform to the grooves in the barrel. In an American .30 gun a .308 bullet is forced out of the gun it has to conform to the .30 bore and .308 grooves to form a tight seal. That's why lead and copper are the primary materials of the bullet. A steel bullet in a steel bore would potentially produce a pipe bomb or at least do significant damage to the bore. Also, the weight of bullets are optimized for their application with the current materials. There is no need or desire to reduce the mass of the bullet. Simply reducing mass for increased velocity can effect the terminal ballistics in all kinds of ways, but you cannot assume that damage will be higher for a variety of reasons. If nothing else the fact that the military has INCREASED the 5.56x45mm from 55gr to 62gr should be enough to doubt your claim. Also steel is about 70% the density of lead, so there would not be a major savings in mass, but aluminum is only 25% the density and it is much closer to the hardness of lead. If you really wanted a light bullet, the aluminum may be the way to go.

Send your message to us

Pre-Painted Aluzinc Steel Coil for Sandwich Wall Thinkness 1.2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords