PPGI, Pre-Painted Steel Coil Prime Quality Blue Color - Aluminum Sheets White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

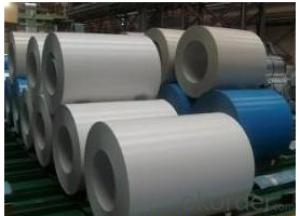

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: Can aluminum sheet be used for automotive heat shields?

- Indeed, aluminum sheet is a suitable option when it comes to automotive heat shields. The automotive industry favors aluminum due to its impressive thermal conductivity and remarkable heat resistance. By reflecting and dispersing heat away from specific regions, it effectively safeguards delicate components from excessive temperatures. Moreover, aluminum possesses the advantages of being lightweight and resistant to corrosion, rendering it an optimal choice for automotive purposes. It finds widespread utilization in diverse heat shield configurations, encompassing exhaust, engine, and under-carriage heat shields.

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: What are the physical properties of aluminum?

- Aluminum possesses a silver-white appearance and is renowned for being a lightweight and malleable metal. It exhibits a relatively low melting point of 660.3 degrees Celsius (1220.5 degrees Fahrenheit) and a boiling point of 2519 degrees Celsius (4566 degrees Fahrenheit). With a density of 2.7 grams per cubic centimeter, it is approximately one-third as dense as steel. Furthermore, aluminum serves as a proficient conductor of both electricity and heat, thus finding widespread utilization in electrical transmission lines and heat sinks. Additionally, it showcases resistance to corrosion, due to the creation of a thin oxide layer on its surface, which renders it suitable for an array of applications across industries, including construction, automotive, aerospace, and packaging.

- Q: How do you calculate the price and weight of aluminum sheet?

- Our company imports more materials. It will be much more expensive if you are short of itAluminum prices have gone up this year

- Q: I need to coat a piece of aluminum with aluminum oxide. Can I do it by just attaching aluminum to an electrode and put it into some water with the other electrode? I know you can make iron oxide that way, but will aluminum work? If it will work, which electrode should I put the aluminum on?

- it is called hard anodization a lot of machine shops can do it - I think there is a certain soup to put it in The Al would be the anode

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation.

- Q: Can aluminum sheets be welded or joined together?

- Yes, aluminum sheets can be welded or joined together using various welding techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding.

Send your message to us

PPGI, Pre-Painted Steel Coil Prime Quality Blue Color - Aluminum Sheets White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords