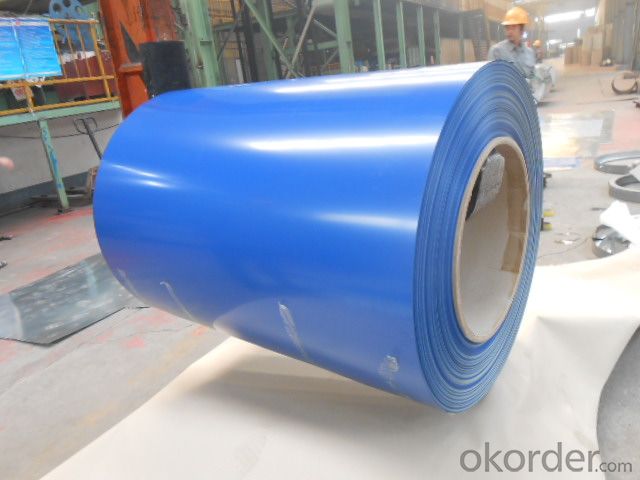

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I want to buy a chain that will last a long time and that i can wear ALL the time.What are the disadvantages to stainless steel jewelry?Does it look as good as silver?Is there much diference in apperance?

- I okorder /... Go for the stainless steel chain if you like it. It does look different than silver and has a more machine like metallic luster (I think). By the way, good stainless steel chains are often more expensive than silver. So don't let anyone laugh at you.

- Q: What are the common challenges in steel coil manufacturing?

- Steel coil manufacturing often encounters several challenges that manufacturers must address. One key issue involves the need to consistently uphold quality standards throughout the manufacturing process. Meeting precise specifications is crucial for steel coils, as any deviations can result in product defects or rejections. Therefore, constant monitoring and implementing quality control measures at each production stage are necessary. Another obstacle involves optimizing production efficiency and minimizing downtime. The production of steel coils encompasses various intricate processes, including cutting, forming, welding, and finishing. Delays or problems in any of these stages can create production bottlenecks, negatively impacting overall efficiency and productivity. Additionally, challenges arise in the handling and storage of steel coils. Due to their weight, steel coils can be challenging to manipulate, necessitating specialized equipment and proper worker training. Moreover, maintaining appropriate storage conditions is vital to prevent damage from factors like moisture, corrosion, or other environmental elements. Maintaining a safe working environment poses another challenge in steel coil manufacturing. Improper operation or maintenance of the equipment and machinery used in the process can lead to hazardous situations. Therefore, ensuring worker safety and implementing suitable safety protocols are crucial to prevent accidents and injuries. Lastly, fluctuating raw material costs and market demands present challenges for steel coil manufacturers. The profitability of the manufacturing process is significantly influenced by the costs of raw materials like iron ore and scrap metal. Furthermore, market demands for specific steel coil types can fluctuate, necessitating manufacturers to adapt and adjust their production accordingly. To overcome these challenges, careful planning, continuous improvement, and effective resource and process management are essential in steel coil manufacturing.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances to provide strength, durability, and structural integrity to the appliance components. They serve as the foundation for various parts, such as the body, frame, and internal structures, ensuring stability and support. Steel coils also contribute to the overall performance and lifespan of appliances by withstanding high temperatures, corrosion, and mechanical stress.

- Q: What are the different types of steel coatings for coils?

- Coils can be coated with various types of steel coatings, each with its own unique properties and advantages. Some of the most commonly used coatings include: 1. Galvanized Coating: This type of steel coating is widely utilized for coils. It involves applying a layer of zinc to the steel, which provides excellent protection against rust and corrosion. It is particularly suitable for outdoor applications or environments with high moisture levels. 2. Galvannealed Coating: Galvannealed steel coating involves subjecting the galvanized steel to additional heat treatment, resulting in a matte finish and improved adhesion for paint. It offers enhanced corrosion resistance and is often preferred in the automotive and construction sectors. 3. Aluminized Coating: Coating steel coils with aluminum provides outstanding heat resistance and corrosion protection. Aluminized steel is commonly employed in exhaust systems and other applications involving high temperatures. 4. Organic Coatings: Steel coils can also be coated with organic materials like paints or powder coatings. These coatings offer additional protection against corrosion and can be customized to meet specific aesthetic requirements, available in a wide range of colors. 5. Tin Coating: Tin-plated steel coils are covered with a layer of tin, which provides excellent solderability and resistance to corrosion. This type of coating is frequently used in the production of cans and other food packaging materials. 6. Phosphate Coating: Phosphate coatings are often applied as a pre-treatment before other coatings to enhance adhesion and corrosion resistance. They create a thin, crystalline layer on the steel surface, facilitating better adhesion of paint or powder coatings. These examples illustrate the diversity of steel coatings available for coils. The choice of coating depends on specific application requirements, considering factors such as corrosion resistance, heat resistance, paint adhesion, and aesthetic preferences.

- Q: How are steel coils used in the manufacturing of automotive frames?

- Steel coils are used in the manufacturing of automotive frames by being shaped and formed into the desired dimensions and then welded together to create a strong and durable structure that provides stability and support to the vehicle.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- Cold Steel makes the best and strongest swords around, ever cut through a steel car hood? Their swords can, I would suggest that if you but one, to also get yourself some life insurance... these things are incredible.

- Q: What are the safety considerations when handling steel coils?

- When handling steel coils, there are several safety considerations that should be taken into account. Firstly, it is essential to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. This protective gear helps to minimize the risk of injuries from sharp edges, flying debris, or accidental contact with the coils. Secondly, it is important to have a clear understanding of the weight and dimensions of the steel coils being handled. Steel coils can be extremely heavy, and improper lifting techniques can result in back strains, muscle pulls, or even more severe injuries. Therefore, it is crucial to use proper lifting techniques, such as bending the knees and keeping the back straight, or utilizing lifting equipment like cranes or forklifts when necessary. Additionally, steel coils can be unstable and prone to rolling or shifting during handling. To prevent accidents, it is crucial to secure the coils properly before moving or stacking them. This can be done by using appropriate lifting attachments, banding the coils together, or utilizing racks or other storage systems specifically designed for steel coils. Furthermore, it is important to be aware of the potential hazards associated with the steel coils, such as sharp edges, oil or grease coatings, or even damage to the coils themselves. It is essential to inspect the coils for any abnormalities or defects before handling them, as well as ensuring that they are stored in a safe and stable manner to prevent accidents. Lastly, proper communication and training are essential when handling steel coils. It is crucial to establish clear communication channels between workers to ensure that everyone is aware of their roles and responsibilities. Additionally, providing training on safe handling techniques, potential hazards, and emergency procedures can help minimize the risk of accidents and injuries. In conclusion, when handling steel coils, it is important to wear appropriate PPE, use proper lifting techniques, secure the coils properly, be aware of potential hazards, and ensure proper communication and training. By following these safety considerations, the risk of accidents and injuries can be significantly reduced.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery to create various components and parts such as frames, brackets, and structural supports. The coils are typically cut, shaped, and welded to form these components, providing strength, durability, and stability to the agricultural machinery.

- Q: If rebar steel is welded together as opposed to 'tied' does it decrease the strength of the steel?

- Gary is right on! To add to it some rebar is heat treated if you weld it it loses the heat treating if you don't re heat treat it it will fail at the welded joint.

Send your message to us

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords