PPGI Color Coated Galvanized Steel Sheet with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

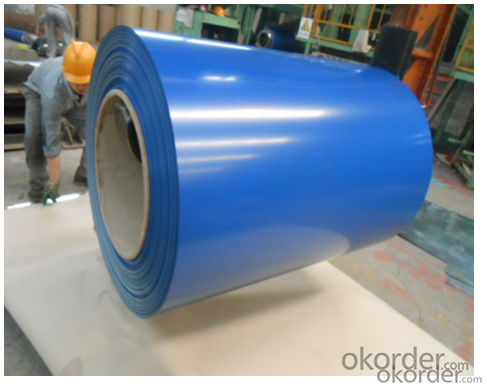

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils processed and shaped into specific products?

- The production of specific steel products involves a series of steps and techniques using different machinery. Initially, steel coils are unwound and flattened using a decoiler and a leveller. This prepares the coils for further processing. Next, the flattened coils are fed into a rolling mill where they undergo cold rolling. This process involves passing the coils through rollers to reduce thickness, improve surface finish, and enhance strength and hardness. After cold rolling, additional processes like annealing or galvanizing may be applied depending on the desired properties of the final product. Annealing involves heating the coils to a specific temperature and slowly cooling them to relieve internal stresses and improve ductility. Galvanizing, on the other hand, involves coating the coils with a layer of zinc to protect against corrosion. Once these treatments are completed, the steel coils are ready to be shaped into specific products. This can be achieved through cutting, stamping, or forming. Cutting involves trimming the coils into desired sizes or lengths using shears or lasers. Stamping involves using a die and press to shape the coils into intricate designs or patterns. Forming, on the other hand, involves bending or shaping the coils with specialized machinery to create curved or contoured products. Finally, the shaped steel products are inspected for quality and undergo any necessary finishing processes like painting or coating. This ensures that the products meet required specifications and are ready for distribution or further assembly. In conclusion, the transformation of steel coils into specific products involves a combination of steps including unwinding, flattening, cold rolling, annealing or galvanizing, cutting, stamping, forming, inspection, and finishing. Each step is essential in producing high-quality steel products used across various industries.

- Q: What are the safety precautions to be taken while handling steel coils?

- Some safety precautions to be taken while handling steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is important to use proper lifting techniques and equipment, such as forklifts or cranes, to avoid strains or falls. Coils should be stored on stable surfaces and secured to prevent them from rolling or falling. Additionally, workers should be trained on proper handling procedures and be aware of the potential hazards associated with sharp edges, heavy weight, and unstable loads.

- Q: How are steel coils used in the manufacturing of automotive wheels?

- Steel coils are used in the manufacturing of automotive wheels as a primary material for the wheel rims. The steel coils are shaped, cut, and welded to create the desired size and design of the wheel rim. They provide high strength and durability, ensuring the wheels can withstand the weight of the vehicle and the impact of road conditions.

- Q: How are steel coils inspected for width using laser measurement?

- Steel coils are inspected for width using laser measurement by placing a laser sensor on one side of the coil and a reflective target on the other side. The laser beam is emitted towards the target, and the reflected beam is analyzed by the sensor. Based on the time it takes for the beam to travel back and the angle of the beam, the width of the steel coil can be accurately measured.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being unwound and fed into a machine that cuts and shapes them into the desired bolt size and shape. The coils provide a continuous and uniform supply of steel, ensuring consistent quality and efficiency in bolt production.

- Q: Why buy recycled steel and from where to buy?

- Recycling old steel is very advantageous to manufacturers because it is always cheaper to use recycled metal scrap in Dubai than to expensively mine iron ore to gain it. Lucky Groups is one the recognized company to deal in recycled steel.

- Q: How are steel coils used in the production of metal panels?

- Steel coils are an essential component in the production of metal panels. These coils, which are typically made from high-quality steel, serve as the raw material for manufacturing various types of metal panels. To begin the production process, the steel coils are first unrolled and flattened using specialized machinery. This allows for a consistent and uniform thickness throughout the sheet. The flattened steel is then cut into the desired length and width, depending on the specific requirements of the metal panel being produced. Once the steel has been cut, it undergoes further processing, such as cleaning and coating. This is done to remove any impurities and protect the steel from corrosion or damage. The coating also enhances the appearance of the metal panel and provides additional durability and longevity. After the cleaning and coating process, the steel sheets are formed into the desired shape using various techniques, such as roll forming or stamping. This allows for the creation of different types of metal panels, including roofing panels, wall panels, and decorative panels, among others. The steel coils used in the production of metal panels are chosen for their strength, durability, and versatility. Steel is known for its excellent structural properties, making it an ideal material for constructing sturdy and long-lasting metal panels. Additionally, steel is highly resistant to environmental factors, such as extreme weather conditions, which further enhances the durability of the metal panels. In conclusion, steel coils play a crucial role in the production of metal panels. They serve as the raw material for manufacturing these panels and undergo various processes to ensure their quality and durability. The use of steel coils allows for the production of a wide range of metal panels that can be used in various industries and applications.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are often used in the manufacturing of consumer goods as a raw material or component for various applications. They can be processed and shaped into different forms, such as sheets, strips, or wires, that are then used in industries like automotive, construction, appliances, and packaging. These coils are utilized to create products like cars, refrigerators, furniture, cans, and many more, providing strength, durability, and versatility to consumer goods.

- Q: How do steel coil manufacturers handle customer complaints?

- Steel coil manufacturers handle customer complaints by following a structured process to address and resolve the issues raised by customers. Firstly, when a customer complaint is received, it is important for the manufacturer to carefully listen and understand the nature of the complaint. This involves actively engaging with the customer to gather all relevant details and information regarding the issue. It is crucial to maintain clear communication and ensure the customer feels heard and valued. Once the complaint has been fully understood, the manufacturer should promptly investigate the situation. This may involve reviewing production records, analyzing quality control measures, or conducting internal inspections. The aim is to identify the root cause of the problem and determine if it was a result of a manufacturing defect, shipping mishap, or any other factor. After the investigation, the manufacturer should provide a timely response to the customer. This response should include an explanation of the findings, an acknowledgment of the customer's concerns, and a proposed solution or resolution. The proposed solution might involve replacing the defective coils, offering compensation, or providing expert advice on how to mitigate the issue. To prevent similar complaints in the future, the manufacturer should also take steps to rectify any internal shortcomings. This could involve revisiting quality control procedures, improving communication among departments, or implementing additional training for employees. Furthermore, steel coil manufacturers should strive to maintain an open and transparent line of communication with customers throughout the complaint handling process. This includes providing regular updates on the progress of the investigation and promptly addressing any further concerns or questions raised by the customer. Overall, the key to handling customer complaints in the steel coil manufacturing industry is to prioritize customer satisfaction and ensure a fair and efficient resolution. By following a structured approach, actively listening to customers, and taking appropriate corrective actions, manufacturers can effectively address customer complaints and maintain positive relationships with their clients.

- Q: How do steel coils contribute to the sustainability of construction projects?

- Steel coils contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable material that can withstand harsh weather conditions, reducing the need for frequent repairs or replacements in buildings and infrastructure. Additionally, steel coils can be recycled, reducing the demand for virgin materials and minimizing waste. The use of steel in construction also enables the creation of lightweight and energy-efficient structures, promoting sustainability by reducing the energy consumption required for heating, cooling, and transportation.

Send your message to us

PPGI Color Coated Galvanized Steel Sheet with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords