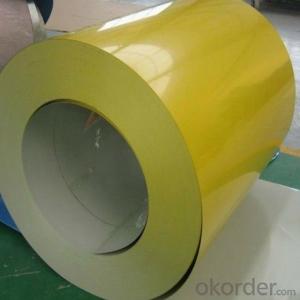

Prepainted Galvanized Steel Sheets In Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATION:

Product name | Prepainted Galvanized Steel Sheets In Coils |

thickness | 0.3mm—1.2mm |

width | 600mm—1250mm |

zinc coating | 60g-225g |

Paint Thickness | Top:15-30um, back:5-10um |

Standard | ASTM A792, JIS G3321, JIS G3317, GB |

Material | SGCC/SGCH |

Base Plate | Cold rolled steel sheet, hot dipped zinc coated steel sheet,hot dipped A-Z coated steel sheet |

Surface Paint | PE,PP |

Color Series | Baosteel color card, color card color bluescope |

Equipment | Double coating double baking |

Packing | 1. standard seaworthy package : waterproof paper/iron sheet/steel strip/steel pallet 2. According to customers' requirements |

Coil Wgt. | 3Mt - 8Mt |

Coil ID | φ508mm,φ610mm |

Payment | T/T or L/C |

Min order | 50 tons |

Capacity | 5000Mt/week |

Delivery time | within 40 days upon receipt original L/C or advance payment |

APPLICATION:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers,

video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- Have you ever watched any of the shows where people are buying lockers at storage facilities? This style lock is used quite often. The reason for the small shackle is to prevent someone from using bolt cutters. Unfortunately, if a thief has a cordless right angle grinder with the right cutting blade they will still be able to remove it. That is what the guys at most of these auctions use to remove them in 10-15 seconds.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the primary component for heat transfer. These coils are typically made from high-quality steel and are designed to efficiently transfer heat between the system's refrigerant and the surrounding air. By passing the refrigerant through these coils, the heat is either absorbed or released, depending on whether the system is providing heating or cooling. This process enables the heating and cooling system to effectively regulate the temperature of a space, providing comfort and maintaining desired conditions.

- Q: What are the different methods of surface inspection for steel coils?

- There are several different methods of surface inspection for steel coils, each with its own advantages and limitations. Some of the most commonly used methods include: 1. Visual Inspection: This is the simplest and most basic method, where an inspector visually examines the surface of the steel coils for any defects such as scratches, dents, or discoloration. While this method is subjective and dependent on the skill and experience of the inspector, it can be a cost-effective option for detecting obvious surface defects. 2. Magnetic Particle Inspection (MPI): This method involves applying a magnetic field to the steel coil and then applying iron particles on the surface. Any defects or cracks in the surface will disrupt the magnetic field, causing the particles to gather at those areas and making the defects visible. MPI is particularly useful for detecting surface cracks and defects that may not be easily visible to the naked eye. 3. Eddy Current Testing (ECT): ECT is a non-destructive testing method that uses electromagnetic induction to detect surface defects on steel coils. A probe with a coil is placed near the surface of the coil, generating an alternating magnetic field. Any changes in the electrical conductivity or magnetic permeability of the steel due to surface defects will cause a change in the induced current, which can be detected and analyzed. ECT is effective for detecting cracks, corrosion, or other surface irregularities. 4. Ultrasonic Testing (UT): This method uses high-frequency sound waves to inspect the surface and subsurface of steel coils. A transducer sends ultrasonic waves into the steel, and the reflected waves are analyzed to detect any changes or anomalies in the material. UT can identify defects such as cracks, delaminations, or voids within the coil, providing valuable information about the overall structural integrity of the steel. 5. Optical Inspection: This method utilizes advanced imaging techniques, such as cameras or laser scanners, to capture high-resolution images of the surface of steel coils. These images can be analyzed for defects, such as scratches, pits, or other irregularities. Optical inspection can provide detailed information and is often used in conjunction with other methods for a comprehensive inspection. It is important to note that each method has its own limitations and may be better suited for specific types of defects or surface conditions. Therefore, a combination of these methods is often employed to ensure a thorough and accurate inspection of steel coils.

- Q: What are the common problems faced during steel coil production?

- During the production of steel coils, several common issues may arise. One of the most frequently encountered problems is the breakage or damage of the coils. This can happen as a result of improper handling or transportation, leading to cracks or fractures. To minimize the risk of coil breakage, it is crucial to adhere to proper handling procedures. Another issue that often arises is coil slippage. This occurs when the coils are not securely stacked or stored, causing them to shift or slide. Coil slippage can cause damage to the coils and potentially lead to accidents or injuries. Therefore, it is essential to have adequate storage systems in place to prevent such slippage. Furthermore, corrosion is a prevalent problem in steel coil production. Corrosion can be caused by exposure to moisture, air, or other corrosive substances. It can result in the deterioration of the steel, reducing its strength and durability. To address this issue, it is necessary to implement effective corrosion prevention measures, such as proper coating or storage techniques. Coil quality issues are another challenge faced in steel coil production. These problems can include inconsistencies in thickness, width, or surface defects on the coils. Various factors, such as improper rolling processes, equipment malfunctions, or material defects, can contribute to these quality problems. Regular quality checks and inspections should be carried out to promptly identify and resolve any issues. Moreover, problems related to coil handling and loading may also arise during steel coil production. Improper lifting or loading techniques can lead to coil damage, resulting in deformations or even accidents. Proper training and education of employees on appropriate handling and loading procedures are crucial to prevent such problems. In conclusion, steel coil production can encounter various challenges, ranging from coil breakage and slippage to corrosion and quality issues. Implementing proper handling, storage, and quality control measures is indispensable in minimizing these problems and ensuring the production of high-quality steel coils.

- Q: How are steel coils used in the manufacturing of tubes?

- Steel coils are commonly used in the manufacturing of tubes as they provide a continuous and uniform supply of high-quality steel material. These coils are processed through various stages, including slitting, forming, and welding, to create tubes of different sizes and shapes. The steel coils are unrolled, cut into strips, and then formed into a cylindrical shape. The edges of the strips are welded together to create a seamless tube. This process ensures the production of strong and reliable tubes that are widely used in industries such as construction, automotive, and manufacturing.

- Q: What are the common methods of testing the strength of steel coils?

- Common methods of testing the strength of steel coils include tensile testing, hardness testing, and bend testing. Tensile testing involves subjecting the steel coil to tension until it reaches its breaking point. This test measures the maximum amount of force the coil can withstand before it fractures. It provides valuable information about the tensile strength, yield strength, and elongation properties of the steel. Hardness testing is another common method used to determine the strength of steel coils. It measures the resistance of the steel to indentation or scratching. Various methods, such as Rockwell, Brinell, or Vickers tests, are employed to measure the hardness of the steel. Hardness testing provides information about the material's ability to resist deformation or wear. Bend testing is performed to evaluate the ductility and flexibility of the steel coil. In this test, the coil is bent to a specific angle and inspected for signs of cracking or fracturing. Bend testing helps determine the material's ability to withstand bending or forming processes without failure. Other methods of testing the strength of steel coils may include impact testing, where a controlled impact is applied to the coil to assess its resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods employed may vary depending on the intended application and industry standards. Additionally, non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can be used to detect internal defects or flaws in steel coils without causing damage to the material.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: Why is it usually scorned by the shooting community to use steel cased ammo (like Wolf)? Always hear corrosive and steel is bad for the extractor/firing pin. Hulp a simpleton out!

- I okorder /

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appeal, protect against corrosion, and improve durability.

- Q: Personally, I like Steel Cage matches to end in pinfalls. One of the biggest selling points of a Cage match is that it is to keep the competitors in and keep others out; essentially ensuring that it's a 1 on 1 match. As a result, I believe that pinfalls or submissions are important - but I know there's a lot of people that believe cage matches should only end in escape. What do you think??

- That exists.. Ts called hell in a cell. And normal cage matches are fine the way they are

Send your message to us

Prepainted Galvanized Steel Sheets In Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords