PPGI Color Coated Galvanized Steel Sheet Of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

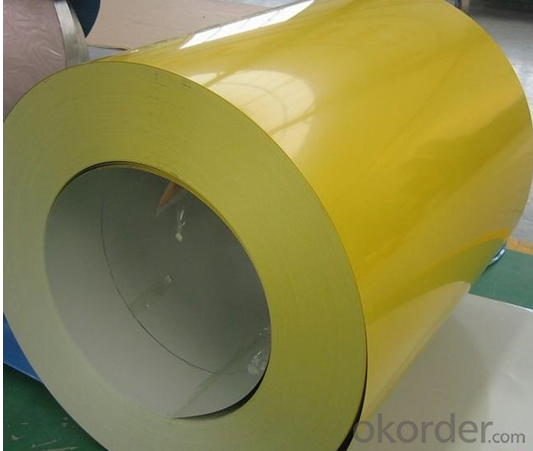

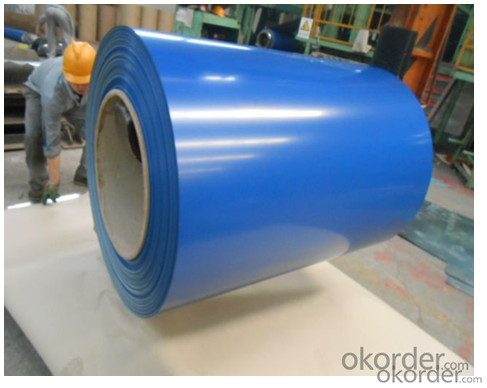

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: In the game RuneScape, the concept of the fictitious metal, Rune has intrigued me. On an equal area AND weight basis (with a possible 10 lb exception) what metal is 256% stronger than steel?

- aluminum

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- If these steel straps are rusting through and on their last legs, a coat of paint is going to be cosmetic at best. Replace these straps with new ones. The originals were either very poorly galvanized, or you live someplace with a very corrosive environment. In any event, paint can't save this sort of thing. Steel brackets serve a real purpose, and after they're weakened, they can't do that anymore. How would your home hold up in an earthquake, for example? What you're proposing doesn't sound safe.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Steel is a conductor while wood is an insulator. There are no free electrons available in wood for conduction of electricity to take place. So wood has more electrical resistivity than that of steel.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, some common dimensions for steel coils used in this industry are typically around 3 to 5 feet in width and 10 to 15 feet in length. The thickness of the steel coils can vary as well, ranging from 0.01 to 0.5 inches. It is important to note that these dimensions are not fixed and may vary based on the specific needs of the railway equipment industry, such as the type of equipment being manufactured or the specific function of the steel coils.

- Q: How are steel coils used in the production of aerospace structures?

- Various methods are employed in the production of aerospace structures, with steel coils being a key component. Aircraft frames and components are commonly manufactured using steel coils. These coils are processed through a series of operations, such as cutting, bending, and welding, to create the necessary structural members of an aircraft, including fuselage sections, wing spars, and landing gear. The preference for steel coils in aerospace applications is due to their exceptional strength and durability. They are capable of withstanding the immense forces and stresses experienced during flight and landing. By utilizing steel coils, aerospace structures are able to maintain the required structural integrity, even in harsh operating conditions. Moreover, steel coils are also utilized in the production of aerospace fasteners and connectors. These components are crucial for securely holding various parts and structures together. Bolts, screws, and rivets, which are essential for assembling different sections of an aircraft, are commonly manufactured using steel coil materials. The strength and reliability of steel coils make them ideal for fastening applications, ensuring the secure connection of aerospace structures. Additionally, steel coils find application in the production of aerospace equipment and machinery. Heavy machinery and specialized equipment are integral to aerospace manufacturing processes. Steel coils are frequently used in the construction of these machines, as they provide robust and sturdy frameworks. Tooling, jigs, fixtures, and molds, which are necessary for producing aerospace structures with precision and accuracy, often incorporate steel coils. In conclusion, steel coils play a vital role in the production of aerospace structures. They are utilized as raw materials for manufacturing aircraft frames and components, fasteners and connectors, as well as aerospace equipment and machinery. The strength, durability, and reliability of steel coils make them indispensable in the aerospace industry, ensuring the safety and integrity of aerospace structures.

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q: What are the different methods of storing steel coils?

- There are several different methods of storing steel coils, including vertical stacking, horizontal stacking, eye-to-the-sky stacking, and interlocking stacking. Each method has its own advantages and considerations based on factors such as space availability, weight distribution, and accessibility for transportation and handling. Ultimately, the choice of storage method depends on the specific requirements and constraints of the steel coil storage facility.

- Q: What are the main factors that affect the strength of steel coils?

- The main factors that affect the strength of steel coils include the composition and quality of the steel used, the manufacturing process employed, the thickness and width of the coils, and the presence of any impurities or defects. Additionally, factors such as temperature, humidity, and storage conditions can also impact the strength of steel coils.

- Q: What are the different surface finishes available for steel coils?

- There are several different surface finishes available for steel coils, including hot rolled, cold rolled, galvanized, coated, and polished finishes.

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appearance, protect them from corrosion, or improve their performance in various applications.

Send your message to us

PPGI Color Coated Galvanized Steel Sheet Of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords