ppgi coil, color coated steel coil, prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D/SGCC/S550GD | Thickness: | 0.165-1.2mm |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | PPGI |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Container Plate | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | coil | color: | ral color or as client color sample |

Packaging & Delivery

| Packaging Detail: | export standard packing |

| Delivery Detail: | as client requirement |

Specifications

ppgi, color coated

1.material:gi coil,gl coil

2.thickness:0.165-1.2mm

3.width:600-1250mm

4.zinc coated: z40-275/az40-150

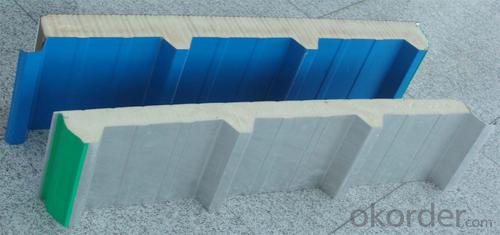

PPGI COIL, Color Coated Steel Coil, Prepainted Steel Coil

About Product Details:

1.material:gi coil/alu zinc steel coil, DX51D/SGCC/S350GD/S450GD/S550GD

2. Zinc Coating: z40-z275,Az40-Az150

3. Thickness:0.165-1.2mm

4. Width:600/610/914/1000/1200/1219/1250mm

5. Paint Coating:top coating: 15um or 20um or more, back coating 5-7um or 10um or as client requirement

6. Color:RAL color or customized as the sample

7. Minimun order:25Tons

8. Packaging Details: Fully seaworthy export packing

9. Coil weight:3-10 ton or client's suggestion

10. Spangle:zero spangle , min spangle , regular spangle, big spang

11. surface treatment: gloss or matt

12. surface coating type: The polyester; the silicon modified polyester, the high durable polyester, gather the leaning vinyl fluoride

13. usage: roofing sheet,

| Standard | Grade | Zinc coating | Width | Thickness | Length | Capacity/Year |

| JIS G3312 | CGLCC | Z40-Z275g | 600-1250mm | 0.165-1.2mm | Coil | 200,000Ton |

| EN 10346 | DX51D+Z/DX53D+Z/S220GD-550GD | Z40-Z275g | 600-1250mm | 0.165-1.2mm | Coil | 200,000Ton |

| ASTM A792 | CS-B/SS255-550 | Z40-Z275g | 600-1250mm | 0.165-1.2mm | Coil | 200,000Ton |

BASIC MATERIAL | CHEMICAL COMPOSITION % | MECHANICAL PROPERTIES | |||||||

C | Si | Mn | S | P | T.S | Y.S | E.L | ||

MPA | MPA | % | |||||||

GL/GI | 0.06 | 0.02 | 0.22 | 0.018 | 0.017 | 346 | 360 | 31 | |

PAINT | MEK | GLOSS | PENCIL | BENDING | REVERSE IMPACT | INSPECT RESULT | |||

μm | |||||||||

30 | OK | 60% | 3H | 3T | 9J | OK | |||

- Q: I noticed a friend's appliances are not magnetic, and mine are. Both are stainless steel. Are there two types of stainless steel or something? Thanks

- Is Stainless Steel Magnetic

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy using weighing scales or load cells. The coils are placed on the scales or load cells, and the weight is measured to ensure it matches the specified weight range.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel is a highly conductive material, allowing for efficient heat transfer. This means that appliances with steel coils, such as refrigerators or air conditioners, can cool or heat up faster, reducing energy consumption. Additionally, steel coils are durable and have excellent heat retention properties, meaning that once the desired temperature is reached, the coils can maintain it for longer periods without consuming additional energy. This helps appliances to operate more efficiently and save on electricity usage.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are shaped and formed into various components such as brake discs, brake pads, and brake calipers. These coils are made of high-quality steel that provides strength and durability, ensuring efficient and reliable braking performance for vehicles.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- One of two things can cause this. Either your pan bottoms are light weight, or you are cooking at too high a temperature.

- Q: What really is the difference between stain-less steel and iron? I only know that iron is an element, and stain-less steel is an alloy...but what else is there?

- Steel is iron that is treated with very specific amounts of carbon (sometimes other specific elements are added which results in different types of steel alloy) which results in greatly increased utility in all aspects of the metal.

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Yes ,i think so. The two most useful properties of the metal form are corrosion resistance, and the highest strength-to-weight ratio of any metal.[4] In its unalloyed condition, titanium is as strong as some steels, but 45% lighter.[5] There are two allotropic forms[6] and five naturally occurring isotopes of this element; 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).[7] Titanium's properties are chemically and physically similar to zirconium.

Send your message to us

ppgi coil, color coated steel coil, prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords