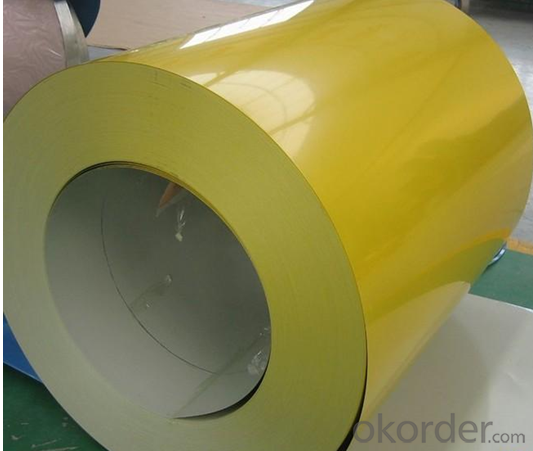

PPGI,Pre-Painted Steel Coil Prime Quality in Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- I like Cerama Bryte. They make several stainless steel cleaning products. I love the Stainless Steel Cleaning Polish Conditioner Wipes. They also make Stainless Steel Appliance Cleaner.

- Q: basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- * okorder /

- Q: What are the different coil coatings available for steel coils?

- There are several different coil coatings available for steel coils, including polyester, silicone modified polyester (SMP), polyvinylidene difluoride (PVDF), plastisol, and epoxy. Each coating has its own unique properties and advantages, such as durability, weather resistance, and color retention, allowing for a wide range of applications in various industries.

- Q: What are the typical coil width options?

- The typical coil width options vary depending on the industry and application, but common options include 12 inches, 18 inches, 24 inches, and 36 inches.

- Q: How are steel coils used in the production of metal panels?

- Metal panels require steel coils as an essential component in their production. These coils, typically made from high-quality steel, act as the raw material for manufacturing different types of metal panels. To initiate the production process, specialized machinery is used to unroll and flatten the steel coils. This process guarantees a consistent and uniform thickness throughout the sheet. Following this, the flattened steel is cut into the desired length and width, depending on the specific requirements of the metal panel being produced. After the steel has been cut, it undergoes further processing, including cleaning and coating. This step aims to eliminate any impurities and safeguard the steel against corrosion or damage. The coating also enhances the appearance of the metal panel and provides additional durability and longevity. Once the cleaning and coating process is complete, the steel sheets are shaped into the desired form using various techniques such as roll forming or stamping. This enables the creation of diverse metal panels, including roofing panels, wall panels, and decorative panels, among others. The selection of steel coils for metal panel production is based on their strength, durability, and versatility. Steel is renowned for its exceptional structural properties, making it the ideal material for constructing sturdy and long-lasting metal panels. Moreover, steel exhibits high resistance against environmental factors like extreme weather conditions, further enhancing the durability of the metal panels. In conclusion, steel coils play a critical role in the production of metal panels by serving as the raw material and undergoing various processes to ensure quality and durability. The utilization of steel coils enables the production of a wide range of metal panels suitable for various industries and applications.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: How are steel coils inspected for paint adhesion?

- Steel coils are inspected for paint adhesion through various methods such as visual examination, tape test, and cross-cut adhesion test. These tests involve visually inspecting the surface for any paint defects, applying adhesive tape to check if the paint adheres properly, and making cross-cuts to assess the adhesion strength.

- Q: I play the guitar and recently found a new type of a guitar called the steel guitar, I don't want to play it or anything it's just I've never seen anything like it before and wonder what the function of it is and what are the differences to a classical guitar

- There okorder /

- Q: How are steel coils inspected for straightness?

- Steel coils are inspected for straightness through a variety of methods to ensure they meet the required quality standards. One common method is visual inspection, where trained inspectors visually examine the coil for any visible defects or deformations that may indicate a lack of straightness. They carefully observe the coil's edges, surface, and overall shape to identify any irregularities. Another method used is measuring the coil's straightness using precision instruments. This involves taking measurements at various points along the coil's length and comparing them against specified tolerances. Techniques such as laser measurements or straightness gauges are employed to accurately assess the deviation from the desired straightness. Furthermore, some coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to identify any internal defects or stresses that could affect the straightness. These tests can reveal hidden flaws that may not be evident through visual inspection alone. In addition, some manufacturers may employ automated inspection systems that utilize advanced technologies like computer vision or artificial intelligence. These systems can quickly scan the coil's surface and analyze it for any deviations from straightness, providing precise measurements and ensuring consistent quality. Overall, the inspection of steel coils for straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods aim to identify any deviations from the required straightness, ensuring that only coils meeting the specified standards are used in various applications.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in the manufacturing of agricultural equipment. Steel coils are used to fabricate various components such as frames, chassis, and structural parts that require strength and durability in agricultural machinery.

Send your message to us

PPGI,Pre-Painted Steel Coil Prime Quality in Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords