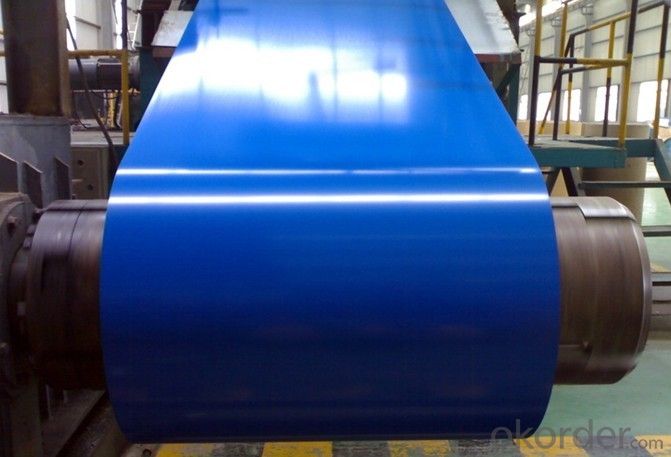

Stable quality ppgi printed prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | PPGI printed prepainted steel coil, Prepainted galvanized steel coil, Stable quality ppgi printed prepainted steel coil |

Advantage | 1.Exquisite technology 2.Advanced production lines 3.High and stable quality products 4.Reputable enterprise 5.Competitive price 6.Good aftersale service |

Thickness | 0.13mm-0.7mm |

Width | 914mm,1000mm,1200mm,1219mm,1220mm,1250mm You also can customize other wide product, like 600mm, 225mm,125m, ect. By the way, the width less than 600mm, it will be no drawback |

Zinc coating | 40-100gsm |

Color | sea blue, white grey, crimson, RAL9002, RAL9006, RAL9016, and other RAL code color |

Application | general commercial using, for deep drawing, for structural components, etc |

Package | 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized |

Product information

Width:600-1500mm,Thickness:0.18-2.00mm

Steel grade:CGCC,SGCC,TDC51D,TDC52D,DX51D

Painting thickness:Front:15-20um,primer:5-7um,Back side:5-7um.

Base material:galvanized steel coil or galvalume steel coil

Zinc coating:60-200g/m2 for galvanized steel coil.60-150g/m2 for galvalume steel coil.

Type of painting:PE,PVDF,SMF or according to the requirements.

Standard:GB/T 12754-2006,ASTM A755M,JIS G3312,EN10169/DIN

Technical:cold rolled

Surface treatment:color coated

Coil ID:508mm/610mm

Package:export standard package or as requirements

Certification:BV/SGS/ISO

Samples:allowed for free.color can be blue,red,white.

Terms:

a)Trade terms:FOB/CFR/CIF

b)Payment terms:T/T,L/C and more favorable terms for old customers.

c)Provid capacity:10000 tons per month

d)MOQ:25 tons or negotiation.

e)Delivery time:10-20 days for 25 tons

f)loading port:Tianjin Port.

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various checks and inspections throughout the production process. These measures may include dimensional checks to ensure the coils meet specified thickness, width, and length requirements. Visual inspections are also conducted to identify any surface defects such as scratches, dents, or rust. Additionally, destructive and non-destructive tests like tensile strength, hardness, and ultrasonic testing are performed to assess the mechanical properties and internal quality of the steel coils. These quality control measures aim to ensure that the steel coils meet the required standards and are fit for their intended applications.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the common coil tests performed for quality control?

- Some common coil tests performed for quality control include tension tests, bend tests, hardness tests, and dimensional checks. These tests help to ensure that the coils meet the required specifications and are of high quality.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: What are the different types of steel coil cutting methods?

- There are several methods used for cutting steel coils, including shearing, slitting, and laser cutting. Shearing involves using sharp blades to cut through the coil, while slitting utilizes circular blades that make multiple cuts to create narrower strips. Laser cutting, on the other hand, employs a focused laser beam to melt or vaporize the steel, resulting in precise and clean cuts.

- Q: How are steel coils stored?

- Steel coils are typically stored in warehouses or outdoor storage yards. They are usually stacked on top of each other in a crisscross pattern to maximize space utilization and prevent them from rolling. Additionally, steel coils may be secured with steel banding or placed on pallets to ensure stability during storage and transportation.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils utilized in the creation of bridges can fluctuate depending on the precise requirements of the bridge undertaking. However, in general terms, the dimensions of steel coils used in bridge construction typically fall within the range of 0.5 to 1 inch in thickness and 36 to 72 inches in width. The length of the coils may also differ, but is commonly around 20 to 40 feet. These dimensions enable the production of various fundamental structural elements, such as beams, columns, and plates, which are indispensable for bridge construction. It is noteworthy that the dimensions may vary based on the specific design and engineering specifications of the bridge project, as well as the type and load capacity of the bridge being constructed.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are commonly used in the manufacturing of furniture as they provide structural support and stability. They are typically used in the construction of sofa frames, mattress foundations, and other furniture pieces that require strength and durability. The coils are often incorporated into the furniture's framework or used as a base for cushions and upholstery, ensuring long-lasting and comfortable products.

- Q: What are the common tests performed on steel coils for quality assurance?

- The common tests performed on steel coils for quality assurance include visual inspection, dimensional analysis, tensile strength testing, hardness testing, and surface quality assessment.

- Q: I bought my Gerber Scout for 29 bucks at the local Walmart a couple months ago, and so far it's performed better than any of my previous knives (a couple of low quality Bucks, and a Winchester). However, my friend just bought a 50 dollar Buck knife and I absolutely love it, so I'm debating trading mine in and pitching in a bit of cash for the same kind.What troubles me is the fact that everybody seems to be bashing 440A steel. I hear a lot of bad things about it; how it is soft, chips easy, dull quickly, etc. How bad is 440A steel really, and would it be worth trading in my Gerber plus about 30 cash for a Buck Vantage Pro? Apparently the Vantage Pro uses S30V steel, so is it really that big of an upgrade, from 440A to S30V? Thank you.

- Its the standard for most knives and its the easiest to sharpen, I have a couple 440 steel knives and they have never failed me, my oldest one is 11 years old and I have stabbed multiple people(in self defense, cut open backpacks, seat belts, fishing string, limes, thin rope, jeans, jackets, pockets, seats, popped tires, moved hot charcoal and other stuff, it just has to be sharpened every now and then. Although I really like carbon knives like KA-BAR's those are amazing and are the only fixed blade knife I would ever buy.

Send your message to us

Stable quality ppgi printed prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords