Aashto M288 Class 1 PP or PET Filament Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PP or PET Woven Geotextile

Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester or polypropylene yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

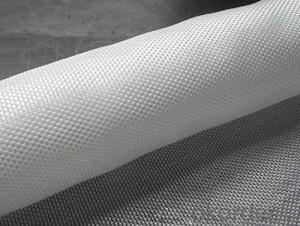

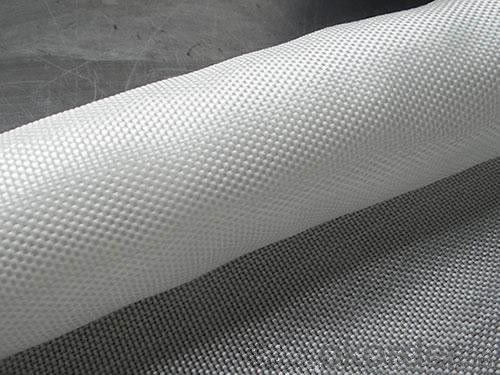

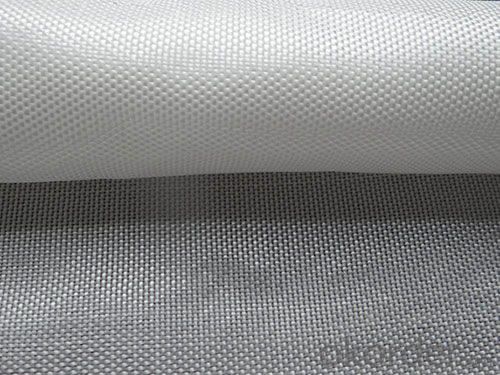

Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing erosion control, filtration, and separation. They are used as a barrier to prevent soil erosion, stabilize the embankments, and retain water within the pond or lake. Geotextiles also act as a filtration medium, preventing the migration of fine particles and allowing water to flow freely. Additionally, they help in separating different layers of soil, preventing mixing and maintaining the structural integrity of the pond or lake.

- Q: What is the high strength to strengthen the composite geotextile

- The correct product name should be high-strength reinforced composite geotextile This is a different from the traditional geotextile new products. Reinforced geotextile is made of high-strength fiber tow and non-woven composite weaving, the process is arranged in parallel fiber bundles, give full play to the role of the yarn. Non-woven mat under which the warp technology will be wrapped around the bundle, so that fiber tow and non-woven together, not only to keep the non-woven filter, but also has the strength of woven cloth. Mainly used in: rivers and lakes, drains, reservoir dam control project and power plant ash dam, mine, airport, cargo yard, railway, highway, tunnel, municipal, environmental protection and other projects, with reinforcement, isolation, Drainage, protection and other functions, is an excellent geotechnical materials; the main role is to seepage and isolation of the grassroots level, to prevent soil erosion, sand, and the embankment foundation of the embankment increased tolerance. The superiority is mainly manifested in the following aspects: high strength composite reinforced geotextile anti-aging durability, the service life can reach and more than 100 years; high strength composite geotextile puncture high strength, physical indicators far more conventional geosynthetics Material strength index; high strength composite geotextile friction coefficient, the adhesion is particularly strong, increasing the adhesion of the isolation layer, taking into account the external factors on the impact of reinforced filter layer reduced; high-strength composite geotextile reinforced acid, alkali , Salt corrosion, in the low temperature and high temperature and UV anti-aging experiments, the physical indicators stable.

- Q: Can geotextiles be used in the construction of golf course bunkers?

- Yes, geotextiles can be used in the construction of golf course bunkers. Geotextiles are often used as a liner or barrier material to separate the bunker sand from the underlying soil, reducing contamination and improving drainage. They help to stabilize the sand and prevent erosion, ensuring the bunker remains in good condition over time.

- Q: Can geotextiles be used in railway track construction?

- Yes, geotextiles can be used in railway track construction. Geotextiles provide various benefits such as soil stabilization, drainage, filtration, and separation. They can be used to improve the performance and longevity of railway tracks by providing reinforcement, preventing soil erosion, and reducing maintenance requirements.

- Q: Geotextile manufacturers are what industry

- Geotextile manufacturing enterprises are textile and leather industry

- Q: Geotextile is used to do anything

- Geotextiles have multiple varieties, there are a variety of uses, different varieties have a different emphasis on different functions. Woven geotextile, or geotextile, can be used for foundation treatment in the reinforcement and isolation and filtration. Non-woven geotextile, mainly used for foundation treatment in the filter and isolation. Can also be used in other projects in the filter. Nonwovens for the example of the filter: now in the municipal engineering around the Yinjing, often because the surrounding groundwater into the Yinjing will take away part of the soil, resulting in the loss of soil around the wells, the results in the perimeter around the wells There is a collapse phenomenon, if the circle around the perimeter of the laying of non-woven geotextile, the side can play a role in filtering, so that groundwater can flow into the Yinjing, but the soil will not lose the purpose of the perimeter around the soil There will be no collapse of the phenomenon.

- Q: What are the advantages of using geotextiles in hydraulic applications?

- There are several advantages of using geotextiles in hydraulic applications. Firstly, geotextiles help in the filtration and separation of soil particles, preventing clogging and maintaining the flow of water. Secondly, they provide reinforcement and stability to soil, enhancing its load-bearing capacity and preventing erosion. Additionally, geotextiles act as a barrier, preventing the migration of fine particles and pollutants, thus improving water quality. Lastly, they are cost-effective and easy to install, making them a practical choice for various hydraulic projects.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in oil and gas industry applications. They are commonly used as a part of erosion control and sediment containment systems, providing stability and protection to the soil and preventing the migration of sediment into water bodies. Geotextiles can also be used in the construction of access roads, drilling pads, and pipeline trenches to improve their durability and reduce maintenance requirements.

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are commonly used as a protective layer in coastal engineering projects to prevent erosion and provide stabilization to the soil or slopes. They can be placed under riprap or other armoring materials to enhance their effectiveness and longevity in protecting coastal areas from wave action and erosion.

- Q: Are geotextiles suitable for use in high-traffic areas?

- Yes, geotextiles are suitable for use in high-traffic areas. Geotextiles are engineered materials that offer high strength, durability, and resistance to wear and tear. They can effectively distribute loads, prevent erosion, and stabilize the ground, making them a suitable choice for high-traffic areas such as roads, parking lots, and construction sites.

Send your message to us

Aashto M288 Class 1 PP or PET Filament Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords