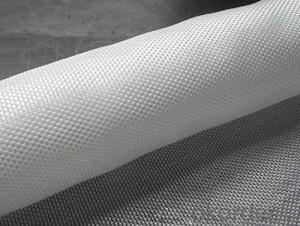

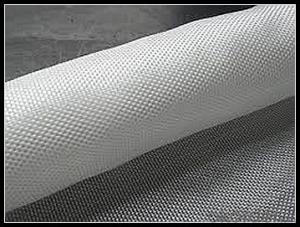

Aashto M288 Class 2 Geotextile - Short Nonwoven High Strength Polyester Fabric Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Separation

CNBM Geotextile acts as a separator between two layers of soil that have different particle size distributions. CNBM Geotextiles are used to prevent road base materials from penetrating into soft underlying sub grade soils, thus maintaining design thickness and roadway integrity. Separators also help to prevent fine-grained sub grade soils from being pumped into permeable granular road bases.

Filtration

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils from migrating into drainage aggregate or pipes while maintaining flow through the system. TexoFib Geotextiles are also used below rip rap and other armour materials in coastal and river bank protection systems to prevent soil erosion.

filtration

Benefits

High soil confinement for greater load distribution

Durable and superior damage resistant

High modulus, for immediate structural support

Unique weave optimizing both strength and filtration properties

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

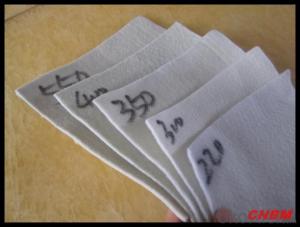

specifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in conjunction with geogrids to provide additional support and stabilization to the soil. The geotextile acts as a separation layer, preventing the intermixing of different soil layers and enhancing the overall performance of the geogrid reinforcement system.

- Q: What are the different geotextile durability test methods?

- There are several different geotextile durability test methods, including the accelerated aging test, the hydrolysis test, the ultraviolet (UV) exposure test, the chemical resistance test, and the abrasion resistance test. These tests are conducted to assess the long-term performance and durability of geotextiles in various environmental conditions.

- Q: What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on factors such as the type and quality of the geotextile, the size of the project, and the specific application. In general, geotextiles can add an additional cost to a project, as they need to be purchased and installed. However, they can also provide cost savings in the long run by reducing the need for expensive soil stabilization measures, increasing the lifespan of structures, and minimizing maintenance and repair costs. Additionally, geotextiles can provide cost-effective solutions for erosion control, slope stabilization, and drainage, which can help prevent costly damages and disruptions.

- Q: What equipment is geotextile equipment?

- This I do not how clear, and detailed you can go to Long Yun machinery manufacturers to see, his home is specialized in producing this equipment manufacturers, hoping to help you to adopt.

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can have both positive and negative effects on soil nutrient availability. On one hand, they can help retain nutrients in the soil by preventing erosion and leaching, thus promoting their availability for plant uptake. On the other hand, geotextiles can also impede nutrient penetration into the soil, potentially reducing their availability for plants. The specific impact of geotextiles on soil nutrient availability depends on factors such as the type of geotextile, its installation method, and the specific nutrient in question.

- Q: 250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q: What are the different methods of installing geotextiles?

- There are several methods of installing geotextiles, including direct placement, trench installation, and anchoring. Direct placement involves simply unrolling the geotextile fabric over the desired area and securing it with stakes or other means. Trench installation involves excavating a trench, placing the geotextile fabric in the trench, and backfilling it with soil or other materials. Anchoring is another method where the geotextile fabric is secured to the ground using anchors, such as pins or staples, to prevent movement or displacement.

- Q: Polyester filament geotextile performance characteristics

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: Geotextile (two cloth a film) to detect the frequency requirements? On behalf of the number?

- Geotextile and geomembrane detection frequency is 100 volumes detection time.

Send your message to us

Aashto M288 Class 2 Geotextile - Short Nonwoven High Strength Polyester Fabric Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords