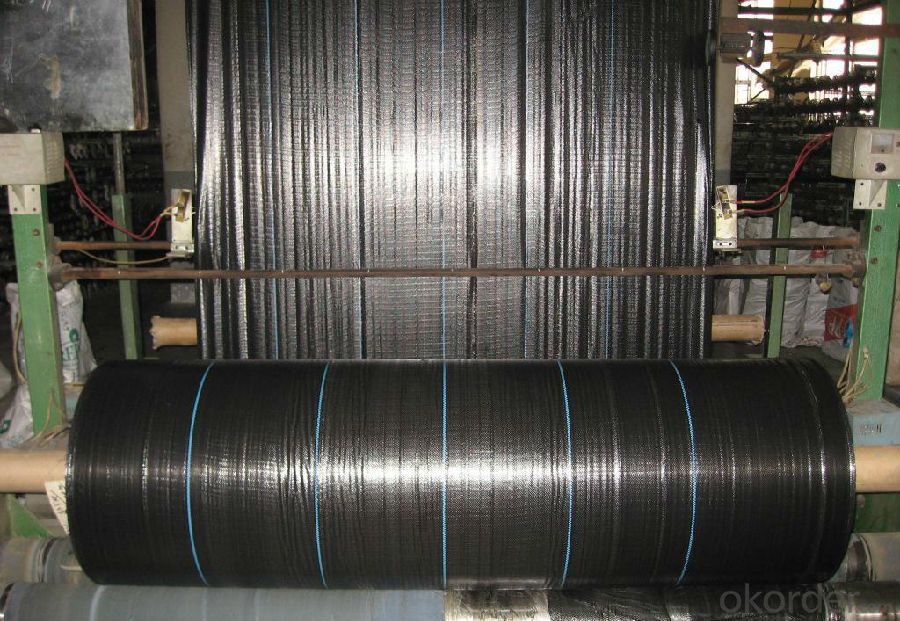

Géotextile Gazon Synthétique PP Geotextile for Construction/Landscape/Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile Introduction

Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Type: 1. Wovens & knitted: use various fibre types in different combinations.

2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Is the case, we detect the company now want to engage in expansion (that is, increase the test items), the need for material to do qualification certification. But I have not done before, do not know their own data done unreasonable. Take the data mainly for reference, know the approximate range of the various parameters. Question added: it is best to have data logging source and derivation formula to support the reasonableness of this result, thank you! More

- Hello, can only help you this, do not know useful to you useless factory production geotextile geomembrane drainage board

- Q: How do geotextiles help in preventing soil erosion on slopes?

- Geotextiles act as a barrier between soil and water, allowing for better drainage and filtration. They stabilize the soil, prevent particle movement, and reduce surface erosion by increasing the overall shear strength of the slope.

- Q: Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q: What are the specifications for geotextiles in landfill liner applications?

- The specifications for geotextiles in landfill liner applications typically include properties such as high puncture resistance, tensile strength, and UV stability to ensure durability and longevity. They should also have a high flow rate to allow for proper drainage and prevent the buildup of excess moisture within the landfill. Additionally, the geotextiles should meet specific thickness and weight requirements to provide sufficient barrier and separation functions.

- Q: What are the different geotextile durability test methods?

- There are various geotextile durability test methods including accelerated aging tests, puncture resistance tests, tensile strength tests, and exposure to environmental conditions such as UV radiation and chemical exposure. These tests help assess the long-term performance and durability of geotextiles in different applications.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing reinforcement and separation functions. They help prevent the migration of fine particles from the subgrade into the ballast, which can lead to ballast degradation and loss of stability. Additionally, geotextiles distribute loads evenly, reducing differential settlement and increasing the overall stability of the ballast layer.

- Q: Do you have to have a mattress on the geotextile?

- 1, geotextile must be washed back to fill or sand protective layer and light compaction to prevent the subsequent construction of the destruction of geotextile, punctured and so on. But also a transition zone, to ease the upper load on the geotextile extrusion, tensile force and so on. 2, "Geotextile Construction Code QB / SNGSG-2004" and "Geosynthetics Application Technical Specifications GB / T-2017" backfill requirements: 1) timely backfill materials, backfill stone maximum drop of not more than 300mm, Heavy earth stones should not roll on the slope of the rolling; 2) fill the compaction should meet the design requirements, backfill 300mm loose layer, light compaction. 3, geotextile introduction: 1), geotextile by synthetic fiber through acupuncture or weaving made of permeable geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Advantages: geotextile with excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with a light weight, high tensile strength, good permeability, high temperature, resistance to Freezing, anti-aging, corrosion-resistant advantages. 2), Disadvantages: in the rigid base waterproof requirements are not applicable (tensile rate does not meet the requirements), easy to break, scratches and so on.

- Q: Are geotextiles suitable for use in mining tailings containment?

- Yes, geotextiles are suitable for use in mining tailings containment. Geotextiles are designed to provide strength, stability, and filtration, making them effective in containing and managing mining tailings. They help prevent the migration of fine particles, control erosion, and enhance the overall stability of the containment system.

- Q: How do geotextiles help in preventing soil erosion in agricultural fields?

- Geotextiles help prevent soil erosion in agricultural fields by acting as a barrier between the soil and the erosive forces such as water and wind. They provide stabilization and reinforcement to the soil, reducing the risk of erosion. Additionally, geotextiles improve water infiltration, reduce surface runoff, and enhance soil moisture retention, promoting healthier plant growth and preventing soil loss.

Send your message to us

Géotextile Gazon Synthétique PP Geotextile for Construction/Landscape/Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords