High Quality Geonet

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 8000 M2 m²

- Supply Capability:

- 300000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

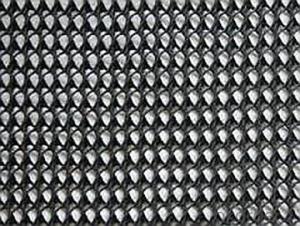

Introduction of geonet:

Geonet is a homogenous and stable structure, Anti-aging, resisting acid and alkaline ect.

Application of geonet:

Make reinforcement treatment for normal soft foundation and sand-fixation gabion, used in drain cushion, side slop, grass planting for slop protection, coastal operation etc

Chief specifications include CE121, CE131, CE151, CE181, DN1 and HF10

Specification of geonet:

Table 1: Unit weight, mesh size and specification of deviation

Property | CE121 | CE131 | CE151 | CE181 | DN1 | HF10 |

Unit weight (g/m2) | 730±35 | 630±30 | 550±25 | 700±30 | 750±35 | 1300±60 |

Mesh size (mm) | (8±1)×(6±1) | (27±2)×(27±2) | (74±5)×(74±5) | (90±5)×(85±5) | (10±1)×(10±1) | (10±1)×(6±1) |

Width Variation (m) | +0.06 0 | |||||

Length Variation (m) | +1 0 | |||||

Table 2. Tensile Strength at Yield

Property | CE121 | CE131 | CE151 | CE181 | DN1 | HF10 |

Tensile Strength at Yield (KN/M) | Vertical and horizontal≥6.2 | Vertical and horizontal ≥5.8 | ≥5.0 | ≥6.0 | Vertical and horizontal l≥6.0 | Vertical and horizontal ≥18 |

- Q: What are the key considerations when using geosynthetic materials in bridge construction?

- When using geosynthetic materials in bridge construction, some key considerations include the selection of the appropriate type of geosynthetic material based on the project requirements, understanding the load-bearing capacity and durability of the material, ensuring proper installation techniques are followed, and conducting regular inspections and maintenance to ensure the long-term performance of the geosynthetic materials. Additionally, it is important to consider the potential environmental impacts and compatibility of the geosynthetic materials with other components of the bridge structure.

- Q: How do geotextile tubes help in coastal erosion control?

- Geotextile tubes, also known as geotubes, play a crucial role in coastal erosion control by acting as barriers against wave action and providing shoreline protection. These large, sand-filled fabric tubes are placed along the coastline, absorbing and dissipating the energy of waves, thus reducing erosion. Additionally, geotextile tubes can be used to create dunes and stabilize beach profiles, preventing the loss of sediment and maintaining the natural balance of coastal ecosystems.

- Q: How do earthwork products contribute to groundwater pollution prevention?

- Earthwork products, such as geotextiles and geomembranes, play a crucial role in preventing groundwater pollution. These materials are used in various construction and engineering projects to create barriers and liners that prevent contaminants from seeping into the ground and reaching the groundwater. By effectively blocking the migration of pollutants, earthwork products help maintain the quality and integrity of groundwater sources, ensuring a safe and sustainable water supply for communities and ecosystems.

- Q: How do geosynthetic clay liners aid in environmental protection?

- Geosynthetic clay liners (GCLs) aid in environmental protection by providing a barrier that prevents the migration of pollutants and contaminants from waste containment facilities into the surrounding soil and groundwater. The clay component of GCLs has high hydraulic conductivity which allows for effective containment and minimizes the potential for seepage. Furthermore, GCLs offer exceptional resistance to chemical degradation, enhancing their ability to withstand harsh environmental conditions. Overall, GCLs play a vital role in safeguarding the environment by ensuring the long-term integrity of waste containment systems and preventing contamination of natural resources.

- Q: What are the advantages of using geotextile tubes for riverbank protection?

- There are several advantages of using geotextile tubes for riverbank protection. Firstly, geotextile tubes are highly effective in preventing erosion and stabilizing the riverbank. They provide a strong barrier against the forces of water, waves, and currents, thereby reducing the risk of bank collapse. Secondly, geotextile tubes are environmentally friendly as they are made from non-toxic materials that do not harm the ecosystem. Additionally, they can be filled with locally available materials such as sand, which makes them cost-effective compared to traditional methods. Lastly, geotextile tubes are easy to install and maintain, requiring minimal labor and resources. Overall, geotextile tubes offer a sustainable and efficient solution for riverbank protection.

- Q: Material chemistry and civil engineering that employment prospects

- At present, many schools of thermal and power engineering are thermal engine direction. Power machinery graduates to enter the major automobile manufacturers for the engine design and development work. The other is power engineering. Including thermal power plant engineering, hydroelectric power engineering, refrigeration and low temperature engineering, air conditioning engineering.

- Q: How do earthwork products help with land reclamation?

- Earthwork products, such as soil amendments, erosion control materials, and geotextiles, are essential tools in land reclamation projects. These products help with land reclamation by stabilizing the soil, improving its fertility, preventing erosion, and promoting vegetation growth. Soil amendments, like compost or organic matter, enhance the soil structure and increase its ability to retain moisture and nutrients, making it more suitable for plant growth. Erosion control materials, such as erosion control blankets or sediment fences, prevent soil erosion by reducing water runoff and protecting exposed soil surfaces. Geotextiles, on the other hand, are used to stabilize slopes, control sediment movement, and prevent soil erosion. Overall, earthwork products play a crucial role in restoring degraded land and transforming it into productive and sustainable areas for various purposes, including agriculture, infrastructure development, or wildlife conservation.

- Q: Can earthwork products be used for constructing embankments?

- Yes, earthwork products can be used for constructing embankments. Earthwork products such as soil, clay, sand, or gravel are commonly used to build embankments, which are raised structures designed to support roads, railways, or waterways. These materials are often compacted and shaped to create a stable and strong embankment that can withstand the weight and pressure of the intended use.

- Q: How do earthwork products contribute to wetland restoration?

- Earthwork products play a crucial role in wetland restoration by providing the necessary materials for building and shaping wetland features. These products, such as soil, clay, and rock, are used to create berms, levees, and other structures that help retain water and prevent erosion in wetland areas. By using earthwork products, wetland restoration projects can successfully recreate natural hydrological conditions, improve water quality, and enhance overall habitat suitability for wetland species.

- Q: What are the benefits of using geopipes in underground drainage systems?

- The use of geopipes in underground drainage systems offers several benefits. Firstly, geopipes are made from high-density polyethylene (HDPE) material, which is corrosion-resistant and durable, ensuring a longer lifespan of the drainage system. Additionally, geopipes have a smooth interior surface, allowing for better flow and preventing blockages caused by sediment buildup. They also have a lightweight and flexible design, making them easy to install and reducing labor costs. Geopipes are also resistant to chemicals and environmental factors, ensuring their effectiveness in various soil and water conditions. Overall, the use of geopipes in underground drainage systems improves the efficiency, longevity, and performance of the system.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1987 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Geonet

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 8000 M2 m²

- Supply Capability:

- 300000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches