High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

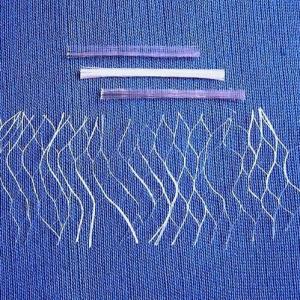

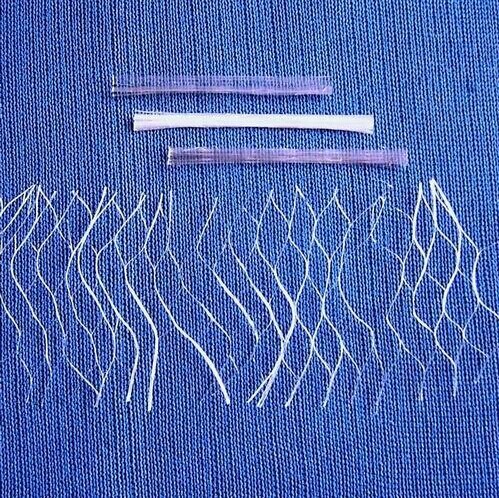

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

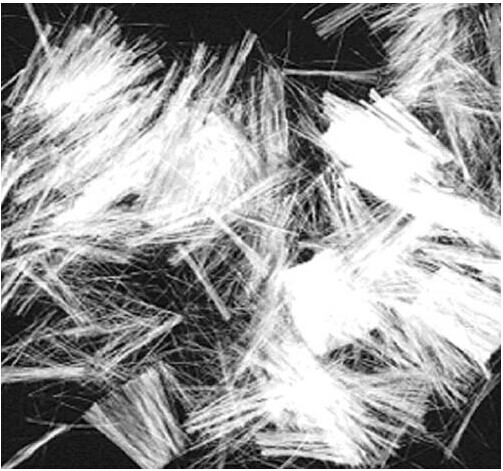

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Introduction of PP Fiber Mesh for Concrete Use

With polypropylene as its raw material..this fiber is produced by special technology. The products appear net-like structure with many fiber monofilaments connected.

When the fiber is put into the concrete ,the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing. And the fiber monofilament or net –like structure will fully stretch, thus the concrete is reinforced by great number of polypropylene fibers.

Technical Data of PP Fiber Mesh for Concrete Use

Density(g/cm3) | 0.91 | Elastic Modulas(MPs) | >3000 |

Length(mm) | 12±1,19±1 | Equivalent Diameter(um) | 100 |

Shape | Beam-like Net | Crack Elongation(%) | 15%-50% |

Acid &Alkali Resistance | Strong | Water-Absorbency | No |

Tensile Strength(MPa) | >350 | Melting Point(C) | 160-170 |

Functions of PP Fiber Mesh for Concrete Use

·increase seepage resistance

·Strengthen spurt & fatigue

·Prolong endurance

·Improve tensile,bending & folding strength

·Improve steel protection

·Improve plastic deformity

·Increase cracking resistance

·Strong acid & alkali resistance and good

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Application of PP Fiber Mesh for Concrete Use

- Q: What are the advantages of using geosynthetic clay liners in irrigation canals?

- Geosynthetic clay liners offer several advantages when used in irrigation canals. Firstly, they have excellent hydraulic conductivity, allowing for efficient water flow and distribution. Secondly, they provide a high level of resistance against seepage, preventing water loss and ensuring a consistent water supply for irrigation. Additionally, geosynthetic clay liners are durable and have a long lifespan, reducing the need for frequent replacements. They are also easy to install, saving time and labor costs. Lastly, these liners are environmentally friendly, as they are made from natural clay materials and do not release harmful chemicals into the surrounding soil or water.

- Q: What are the different surface textures available in earthwork products?

- There are several surface textures available in earthwork products, including smooth, textured, brushed, honed, and polished finishes. Each texture offers a unique aesthetic appeal and can be chosen based on personal preference and the desired look for the project.

- Q: Are earthwork products suitable for building retaining ponds?

- Yes, earthwork products are suitable for building retaining ponds. Earthwork products, such as soil, gravel, and clay, can be used to construct the embankments and linings of retaining ponds. These materials provide stability and prevent water from seeping through the pond walls. Additionally, earthwork products can be shaped and compacted to create the desired slope and capacity of the retaining pond.

- Q: Can geosynthetics be used for lining hydraulic fracking ponds?

- Yes, geosynthetics can be used for lining hydraulic fracking ponds. Geosynthetics, such as geomembranes, are often used to provide a barrier between the pond and the surrounding environment. They can effectively prevent the seepage of fluids, contaminants, and chemicals, ensuring the protection of groundwater and soil. Geosynthetics also offer durability, flexibility, and resistance to punctures, making them suitable for the demanding conditions of hydraulic fracking operations.

- Q: How are geosynthetic materials used in railway platform construction?

- Geosynthetic materials are used in railway platform construction to provide stabilization, reinforcement, and drainage solutions. They are commonly used in the subgrade and subbase layers to improve the strength and stability of the platform. Geotextiles are often used as a separator between the subgrade and ballast layer to prevent mixing and maintain proper drainage. Geogrids are used to reinforce the soil and distribute the load more effectively, reducing settlement and increasing the platform's longevity. Geocomposites can also be utilized to provide both reinforcement and drainage functions in a single product. Overall, geosynthetics play a crucial role in enhancing the performance and durability of railway platforms.

- Q: What are the different types of geotextile fabrics available?

- There are several different types of geotextile fabrics available, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Woven geotextiles are made by interlacing fibers in a pattern to create a strong and durable fabric. Non-woven geotextiles are created by bonding fibers together using heat, chemicals, or mechanical processes. Knitted geotextiles are produced by interlocking loops of yarn to form a flexible and stretchable fabric. Each type of geotextile fabric has its own unique characteristics and is used for various applications in civil engineering and construction projects.

- Q: How do concrete barriers enhance safety on construction sites?

- Concrete barriers enhance safety on construction sites in several ways. Firstly, they provide a physical barrier that prevents vehicles and pedestrians from entering restricted areas, thereby reducing the risk of accidents and injuries. Additionally, these barriers can mitigate the impact of any potential collisions, protecting workers and equipment from damage. Their sturdy construction and weight also make them resistant to strong winds, which helps maintain stability and prevents accidents caused by falling debris. Overall, concrete barriers play a crucial role in ensuring a safer working environment on construction sites.

- Q: Can earthwork products be used in agricultural applications?

- Yes, earthwork products such as soil, gravel, and mulch can be used in various agricultural applications. Soil can be used for cultivating crops, improving drainage, and creating raised beds. Gravel can be used for pathways and driveways, while mulch can help retain moisture, control weeds, and improve soil quality in gardens and landscapes.

- Q: How do earthwork products contribute to slope stabilization and erosion control on highways?

- Earthwork products, such as geotextiles, geogrids, and erosion control blankets, play a vital role in slope stabilization and erosion control on highways. These products are designed to enhance the stability of slopes and prevent erosion by providing a barrier against soil movement and water flow. Geotextiles offer reinforcement and filtration properties, improving soil strength and allowing water to drain, reducing the risk of landslides and erosion. Geogrids provide additional strength to soil structures, increasing their stability and resistance to slope failure. Erosion control blankets protect exposed surfaces from erosion caused by rainfall and wind, promoting vegetation growth and reducing sediment runoff. Overall, these earthwork products are essential in ensuring the safety and longevity of highways by effectively managing slope stability and preventing erosion.

- Q: How do earthwork products contribute to soil moisture retention?

- Earthwork products, such as contour ploughing, terracing, and mulching, play a crucial role in retaining soil moisture. Contour ploughing helps to slow down water runoff and allows water to infiltrate the soil, thus increasing soil moisture levels. Terracing prevents soil erosion by creating flat areas on slopes, which helps retain water in the soil. Mulching, on the other hand, acts as a protective layer over the soil, reducing evaporation and allowing the soil to retain moisture for longer periods. Overall, these earthwork techniques contribute to improved soil moisture retention, which is essential for plant growth and ecosystem health.

Send your message to us

High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches