Velocity Slope Plastic PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Plastic PP Biaxial Geogrid Description:

Plastic PP Biaxial Geogrid Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Main Features of Plastic PP Biaxial Geogrid :

Plastic PP Biaxial Geogrid is Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

To lay the geogrid in the backfill soil can increase the shearing strength and the whole character in middle terms, reduce the mid-term filling quantity, make the soft base more convenient, lower the construction cost.

When used in the dam design, it can be as the muscle structure to improve the bearing distortion performance of the dam to avoid breaking.

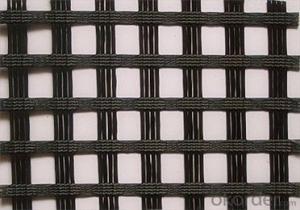

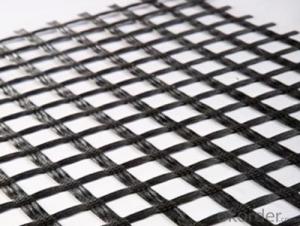

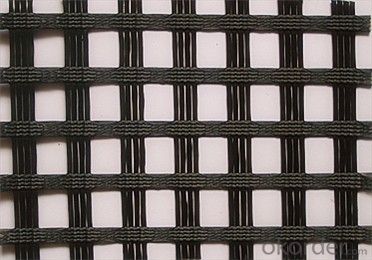

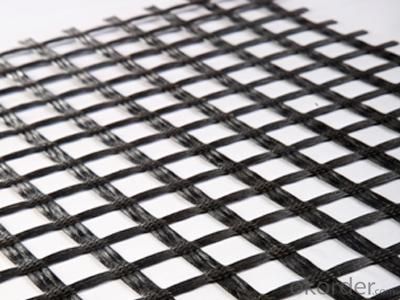

Plastic PP Biaxial Geogrid Images

Plastic PP Biaxial Geogrid Specification:

Item | Art. No. | PLB010201 | PLB010202 | PLB010203 | PLB010204 | PLB010205 |

Specs | TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | |

Unit weight,g/m2 | 370±50 | 450±50 | 550±50 | 700±50 | 1100±50 | |

Width,m | 1.0+0.2/-0 or 2.0+0.2/-0 | |||||

Tensile strength,kN/m≥ | 25 | 35 | 50 | 80 | 110 | |

Elongation,%≤ | 12 | |||||

Tensile strength at 2% strain,kN/m≥ | 6 | 9 | 10 | 23 | 30 | |

Tensile strength at 5% strain,kN/m≥ | 12 | 18 | 25 | 44 | 60 | |

Roll length,m | 50+0.25/-0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing reinforcement and stabilization to the base layer of the pavement. They distribute the load more evenly, preventing localized stress and deformation. This helps to maintain the integrity and structural stability of the pavement, reducing the potential for rutting, cracking, and other forms of distress.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- The factors that affect the performance of geogrids under cyclic loading include the type and quality of the geogrid material, the design and installation of the geogrid, the magnitude and frequency of the cyclic loading, the soil properties and conditions, and the duration of the cyclic loading.

- Q: Can geogrids be used in reinforcement of stormwater management systems?

- Yes, geogrids can be used in the reinforcement of stormwater management systems. Geogrids are commonly used to reinforce retaining walls, slopes, and soil structures, and they can also provide reinforcement and stability to stormwater management systems such as detention ponds, infiltration basins, and bio-retention cells. By installing geogrids, the system can better withstand the forces exerted by stormwater runoff, preventing soil erosion and maintaining the overall integrity of the structure.

- Q: Peel force mainly in the size of raw materials

- The tensile strength of the welded joints!

- Q: Are geogrids resistant to biological fouling?

- Yes, geogrids are typically resistant to biological fouling.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by enhancing the stability and resistance to seismic forces. The geogrids act as a reinforcement material, increasing the tensile strength and preventing soil movement during seismic events. They help distribute the seismic forces more evenly, reducing the potential for slope failure and improving overall slope stability.

- Q: What is the market price of the geotechnical grid in 2017

- (1) the first accurate release of subgrade slope line, in order to ensure the roadbed width of each side of the widened 0.5m, soil drying good leveling by 25T after vibroll pressure two times, then 50T shock pressure of four times, how much is the uneven supply market price? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong local earthwork grid with artificial coordination.

- Q: Can geogrids be used in retaining walls for highway sound barriers?

- Yes, geogrids can be used in retaining walls for highway sound barriers. Geogrids are commonly used in retaining walls to reinforce the soil and provide stability. They can enhance the structural integrity of the retaining wall and help it withstand the lateral pressure exerted by the soil. Additionally, geogrids can also improve the overall performance of sound barriers by reducing noise transmission through the wall.

- Q: What are the factors that affect the design of geogrid installations?

- There are several factors that can influence the design of geogrid installations. Firstly, the type and condition of the soil plays a crucial role as it determines the required strength and stability of the geogrid. The load that the geogrid will be subjected to is another important factor, as it dictates the necessary tensile strength and stiffness of the geogrid. Additionally, the slope and geometry of the project site need to be considered to ensure proper installation and performance of the geogrid. The climate and environmental conditions, such as temperature and moisture, can also impact the design, as they can affect the durability and long-term performance of the geogrid. Finally, the availability and cost of materials, as well as any relevant regulations or design standards, should be taken into account during the design process.

- Q: How much is the overlap length of Geogrid

- GB / T 17689-2008 geosynthetics Plastic Geogrid

Send your message to us

Velocity Slope Plastic PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords