Monolithic Refractories for Iron and Steel Industry - Portland Cement Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portland Cement Castable for Fireplaces and Industrial Furnaces

Product Description:

Portland cement castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

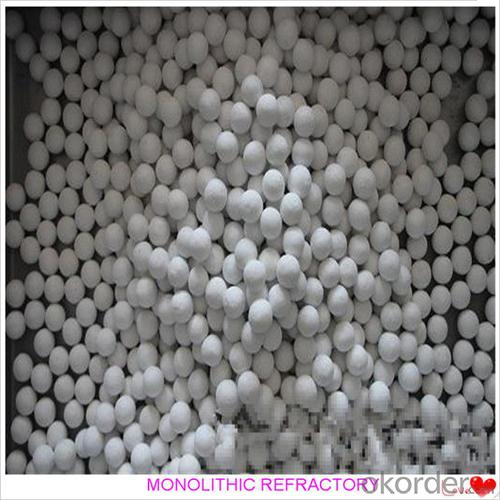

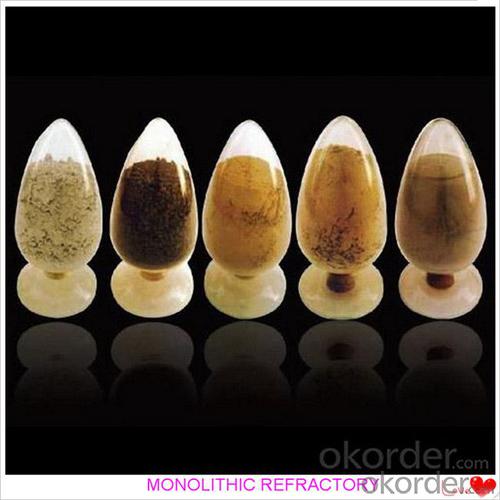

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: How do monolithic refractories enhance the performance and longevity of furnaces?

- The performance and longevity of furnaces can be greatly improved through the use of monolithic refractories. These specialized materials are designed to withstand harsh conditions, such as high temperatures, thermal shock, and chemical exposure, making them an ideal choice for lining furnaces. One major advantage of monolithic refractories is their excellent insulation properties, which minimize heat loss and maximize energy efficiency. This insulation ensures that the furnace maintains a consistent temperature, allowing for more effective and efficient heating processes. Additionally, it prevents external factors from interfering with the internal temperature, ensuring stable and controlled heating operations. Another benefit of monolithic refractories is their high resistance to thermal shock. Furnaces often experience rapid temperature changes, but these refractories can handle such fluctuations without cracking or spalling, preserving the integrity of the furnace lining. This resistance to thermal shock also enhances safety by reducing the risk of sudden failure or damage to the furnace structure. Furthermore, monolithic refractories exhibit excellent chemical resistance, making them highly durable in aggressive environments. Furnaces are frequently exposed to corrosive gases, molten metals, and chemical reactions, but these refractories can withstand these harsh conditions, protecting the furnace lining and preventing contamination of heated materials. Moreover, monolithic refractories offer easy installation and repair. Unlike traditional brick refractories that require time-consuming construction, monolithic refractories can be cast or gunned into place, allowing for quick and efficient installation. Additionally, if any damage occurs, these materials can be easily patched or repaired, minimizing downtime and ensuring uninterrupted furnace operation. In conclusion, the use of monolithic refractories greatly enhances furnace performance and longevity. Their insulation properties, resistance to thermal shock, chemical durability, and ease of installation and repair make them a valuable choice for manufacturers looking to improve furnace efficiency, maintain consistent temperatures, ensure safety, and prolong furnace lifespan.

- Q: What are the challenges in recycling monolithic refractories?

- There are several challenges in recycling monolithic refractories that make the process more complex compared to other materials. Firstly, monolithic refractories are designed to withstand high temperatures and harsh conditions, making them highly resistant to wear and tear. This durability also poses a challenge in the recycling process, as it requires specialized techniques and equipment to break down and separate the refractory material. Secondly, monolithic refractories often contain various additives and binders, such as clay, cement, and other organic compounds, which can complicate the recycling process. These additives may need to be removed or separated from the refractory material before it can be recycled effectively. Additionally, monolithic refractories can be contaminated with other materials, such as metal oxides, slag, and impurities, during their service life. These contaminants can affect the quality and properties of the recycled refractory material, requiring thorough cleaning and purification processes. Moreover, the logistics involved in collecting and transporting monolithic refractories for recycling can be challenging. Refractories are often used in large quantities in industrial settings, and their removal and transportation can be costly and time-consuming. Furthermore, finding suitable recycling facilities with the necessary equipment and expertise to handle monolithic refractories can be limited, especially in certain regions. Lastly, economic factors play a role in the challenges of recycling monolithic refractories. The cost of recycling and processing the refractories may not always be financially viable compared to using virgin materials. This can discourage companies from investing in recycling programs and contribute to the lower demand for recycled refractory materials. Overall, the challenges in recycling monolithic refractories mainly stem from their durability, complex composition, contamination, logistics, and economic considerations. However, advancements in technology and increased awareness of the environmental benefits of recycling may help overcome these challenges and promote the sustainable reuse of refractory materials.

- Q: How do monolithic refractories perform in reheating furnace applications?

- Monolithic refractories perform exceptionally well in reheating furnace applications due to their excellent thermal shock resistance, high temperature stability, and superior insulation properties. They are able to withstand the extreme temperatures and rapid temperature changes that occur during the reheating process, ensuring consistent and efficient heat distribution. Additionally, their flexible and easy-to-install nature makes them an ideal choice for lining the complex geometries of reheating furnaces, resulting in improved performance and extended service life.

- Q: What are the key properties of ramming mixes used for monolithic refractory installations?

- Ramming mixes for monolithic refractory installations must possess several key properties. Firstly, they need to have high thermal stability to withstand extreme temperatures and thermal cycling. This ensures that the mix remains intact under varying thermal conditions. Secondly, a high density is necessary to resist thermal conductivity and minimize heat loss. This helps maintain the desired temperature in the refractory lining. Thirdly, low porosity is crucial to reduce the penetration of molten metals or slag, enhancing the durability of the installation. Additionally, good mechanical strength is required to withstand stresses and loads, preventing physical damage. The mixes should also exhibit chemical resistance to protect against corrosive substances. Furthermore, they should be easy to install and work with, allowing for efficient installation. Lastly, a controlled setting time is important to allow for proper placement and consolidation. Overall, these properties contribute to the performance and longevity of the refractory lining in high-temperature applications.

- Q: How do monolithic refractories resist chemical attack from molten metals and slags?

- Monolithic refractories are designed to resist chemical attack from molten metals and slags through a combination of factors. Firstly, monolithic refractories are typically made from high-quality materials that have excellent chemical resistance properties. These materials, such as alumina, magnesia, or silica, have a stable chemical structure that can withstand the corrosive nature of molten metals and slags. Secondly, monolithic refractories are often formulated with additives or binders that enhance their resistance to chemical attack. These additives can improve the refractory's ability to form a protective layer on its surface, which acts as a barrier between the refractory material and the corrosive molten metal or slag. Additionally, monolithic refractories are often designed with a dense microstructure that limits the penetration of molten metals and slags. The dense structure minimizes the pathways through which corrosive agents can reach the refractory material, reducing the risk of chemical attack. Moreover, monolithic refractories can be installed with proper joint design and anchoring systems to prevent the infiltration of corrosive substances. This ensures that the refractory lining remains intact and effectively resists chemical attack. Overall, the combination of high-quality materials, additives, dense microstructure, and proper installation techniques contribute to the ability of monolithic refractories to resist chemical attack from molten metals and slags, thereby extending their lifespan and maintaining the integrity of the refractory lining in high-temperature applications.

- Q: How do monolithic refractories improve the performance of ladles and tundishes?

- Monolithic refractories play a crucial role in improving the performance of ladles and tundishes in various ways. Firstly, they enhance the thermal insulation properties of these vessels. Ladles and tundishes are exposed to extremely high temperatures during the steelmaking process, and monolithic refractories act as a barrier, preventing the heat from escaping and maintaining the desired temperature. This insulation helps in minimizing heat loss and reducing energy consumption. Secondly, monolithic refractories offer excellent resistance to chemical corrosion and erosion. The ladles and tundishes come into contact with molten metal and various fluxes, which can cause severe corrosion and erosion. The use of monolithic refractories protects the vessels from chemical attacks and extends their lifespan. This not only saves costs associated with frequent repairs or replacements but also ensures the integrity and safety of the vessels. Furthermore, monolithic refractories provide superior mechanical strength and structural stability. Ladles and tundishes need to withstand the weight of the molten metal and the stresses induced during pouring and handling. Monolithic refractories possess high mechanical strength, allowing them to withstand these loads and maintain their shape and integrity. This leads to a reduction in downtime and increases the productivity of the steelmaking process. Moreover, monolithic refractories offer flexibility in design and installation. They can be shaped and applied in various configurations, allowing for customization according to the specific requirements of ladles and tundishes. This flexibility ensures a better fit and improved performance of the refractories, ultimately enhancing the overall efficiency of the vessels. In summary, monolithic refractories improve the performance of ladles and tundishes by providing enhanced thermal insulation, superior resistance to chemical corrosion and erosion, increased mechanical strength, and flexibility in design and installation. These benefits contribute to the longevity, efficiency, and cost-effectiveness of ladles and tundishes in steelmaking operations.

- Q: How are monolithic refractories installed in iron and steel production processes?

- Monolithic refractories are installed in iron and steel production processes using various methods depending on the specific application and requirements. The installation process typically involves the following steps: 1. Surface Preparation: Before installing monolithic refractories, the surface where they will be applied must be properly prepared. This involves cleaning and removing any loose materials, dust, or contaminants from the substrate. 2. Mixing: Monolithic refractories consist of different materials such as aggregates, binders, and additives. These components are mixed in specific proportions to achieve the desired properties and consistency. The mixing process can be done manually or using mechanical mixers. 3. Application: There are different techniques for applying monolithic refractories, including gunning, casting, ramming, and troweling. The chosen method depends on factors such as the shape of the structure, accessibility, and required thickness. - Gunning: This method involves using a gunning machine to spray the refractory material onto the surface. It is commonly used to repair or patch existing linings or for rapid installation in areas that are difficult to access. - Casting: In casting, the refractory material is poured into molds or forms and left to set and harden. This method is suitable for creating complex shapes and large-sized components. - Ramming: Ramming involves manually or mechanically compacting the refractory material into a mold or form using a ramming tool. This technique is commonly used for lining induction furnaces, ladles, and other equipment. - Troweling: Troweling is a manual method where the refractory material is applied and smoothed using a trowel. It is often used for smaller repairs or touch-ups. 4. Curing: After the refractory material is applied, it needs to be cured to achieve its optimum strength and performance. Curing involves allowing the material to dry and harden at a controlled temperature and humidity for a specified period. This step is crucial to ensure the long-term durability and resistance of the monolithic refractory lining. Overall, the installation of monolithic refractories in iron and steel production processes requires careful preparation, proper mixing, and the appropriate application technique. It is essential to follow manufacturer guidelines and industry best practices to ensure a successful installation that meets the specific needs of the production process.

- Q: How are monolithic refractories manufactured?

- Monolithic refractories are manufactured by combining various raw materials, such as aggregates, binders, and additives, with water to create a workable mixture. This mixture is then shaped into the desired form, either by casting, gunning, or ramming. Afterwards, the shaped refractory is dried and fired at high temperatures to achieve the desired strength and thermal properties. The manufacturing process of monolithic refractories allows for flexibility in design and installation, making them suitable for a wide range of applications.

- Q: What are the typical properties of monolithic refractories used in iron and steel industry?

- Monolithic refractories used in the iron and steel industry generally possess several key properties that make them suitable for the harsh operating conditions in these industries. Firstly, monolithic refractories have excellent thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling, which is crucial in the iron and steel industry where the heating and cooling processes can be highly intense. Secondly, these refractories exhibit high refractoriness, meaning they can withstand extremely high temperatures without losing their strength or shape. This is essential in environments where temperatures can reach well above 1000 degrees Celsius. Additionally, monolithic refractories used in the iron and steel industry are known for their excellent corrosion resistance. They can resist the corrosive effects of molten metals, slags, and gases that are commonly encountered in these industrial processes. Furthermore, these refractories have good mechanical strength and abrasion resistance, allowing them to withstand the physical stresses and wear caused by handling and mechanical operations. Another important property of monolithic refractories is their ability to form strong bonds with the existing refractory lining. This ensures a secure and long-lasting installation, reducing the risk of failure and minimizing downtime for maintenance or repairs. Lastly, these refractories often have low porosity, which prevents the infiltration of molten metal or slag into the lining. This helps to maintain the integrity of the refractory structure and prolong its service life. Overall, the typical properties of monolithic refractories used in the iron and steel industry include thermal shock resistance, high refractoriness, corrosion resistance, mechanical strength, strong bonding, and low porosity. These properties collectively contribute to the efficient and reliable operation of iron and steel manufacturing processes.

- Q: How do monolithic refractories improve the durability of furnace linings?

- Monolithic refractories improve the durability of furnace linings by providing a seamless and continuous structure that eliminates joints and weak points. This eliminates the risk of thermal shock and cracking, resulting in a longer lifespan for the furnace lining. Additionally, monolithic refractories offer better resistance to chemical attack, abrasion, and thermal stress, further enhancing the durability of the furnace lining.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Portland Cement Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords