Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

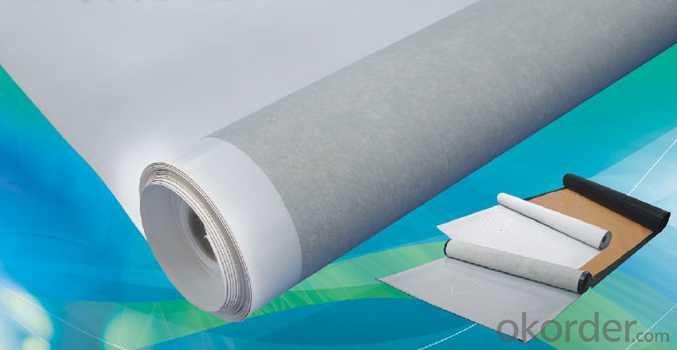

Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- The appearance of a surface can be affected by a waterproofing membrane. When it is applied to a wall or floor, the membrane acts as a barrier to prevent water or moisture from entering. This process typically involves adding a coating or layer that can change the texture or shine of the surface. Occasionally, the membrane might result in a slight color variation or darken the surface. Nevertheless, there are transparent or colorless waterproofing membranes accessible that have minimal impact on the appearance of the surface. Ultimately, the extent to which the appearance is influenced depends on the specific type of waterproofing membrane utilized and the desired aesthetic result.

- Q: Can a waterproofing membrane be used on tunnels with soundproofing systems?

- Tunnels with soundproofing systems can benefit from the use of a waterproofing membrane. It is common practice to integrate waterproofing membranes with soundproofing systems in tunnels. This is because tunnels are prone to water infiltration, which can cause structural damage and impact the performance of the soundproofing system. By applying a waterproofing membrane, the tunnel can be shielded from water intrusion, ensuring the durability and efficacy of the soundproofing system. Moreover, the waterproofing membrane aids in maintaining a dry and comfortable environment in the tunnel, which is essential for the efficient operation of the soundproofing system. Therefore, combining a waterproofing membrane with a soundproofing system is highly recommended in tunnels to provide both water protection and sound insulation.

- Q: Can a waterproofing membrane be used on iron surfaces?

- Indeed, iron surfaces can benefit from the utilization of a waterproofing membrane. Normally composed of rubber, bitumen, or polyurethane, these membranes are specifically engineered to establish a barrier against water and moisture. They possess the capacity to adhere to diverse surfaces, including iron, and offer safeguarding against water penetration. By applying a waterproofing membrane in a precise manner, one can successfully seal and waterproof iron surfaces, effectively deterring corrosion and prolonging the material's longevity. It is of utmost significance to select a waterproofing membrane that is compatible with iron and meticulously adhere to the manufacturer's guidelines regarding installation and upkeep.

- Q: Can a waterproofing membrane be used on tunnels with vehicular traffic?

- Yes, a waterproofing membrane can be used on tunnels with vehicular traffic. Waterproofing membranes are commonly employed in tunnels to prevent water infiltration and protect the structure from moisture damage. These membranes are designed to withstand heavy loads and provide a durable and reliable barrier against water penetration. However, it is crucial to choose a membrane specifically engineered for vehicular traffic tunnels to ensure it can withstand the dynamic forces and stress imposed by vehicles.

- Q: Can a waterproofing membrane be applied to concrete surfaces?

- Yes, a waterproofing membrane can be applied to concrete surfaces.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas to provide protection against water damage and ensure the longevity of the seating structure.

- Q: Can a waterproofing membrane be used on precast concrete block surfaces?

- Precast concrete block surfaces can benefit from the application of a waterproofing membrane. These membranes are commonly used to safeguard below-grade structures, like basements and foundations, from water infiltration. When constructing these structures, precast concrete blocks are frequently utilized, and the use of a waterproofing membrane can prevent water from seeping into the concrete and causing harm. The membrane acts as a barrier, prohibiting water from passing through while still allowing the concrete to breathe and release any accumulated moisture. Furthermore, waterproofing membranes can enhance the overall durability and lifespan of precast concrete blocks by shielding them from moisture-related problems such as cracking, spalling, and corrosion. It is crucial to select a waterproofing membrane that is specifically designed for below-grade applications and is compatible with concrete surfaces to ensure proper adhesion and long-term efficacy.

- Q: Can a waterproofing membrane be used for retaining walls?

- A waterproofing membrane is suitable for retaining walls as it helps to prevent water from penetrating and causing damage or structural failure. These membranes, made of materials like rubber, PVC, or bituminous compounds, are installed on the inner side of the retaining wall to create a barrier against water infiltration. In addition to protecting the wall's stability, some membranes also offer resistance to root penetration, UV protection, and flexibility to accommodate movement. However, it is crucial to consider factors such as the type of retaining wall, water pressure, and local climate conditions when selecting the right waterproofing membrane. It is advisable to consult with a professional engineer or contractor to ensure the most suitable waterproofing solution for your specific retaining wall project.

- Q: What is the PEDM waterproofing membrane material?

- Process: clean up the grassroots → brushing the primary treatment agent → additional layer of treatment → film paste surface coating → base surface coating → coil bonding, exhaust, compaction → coil joint bonding, compaction → roll Material end of the head and edge processing → do protection.

- Q: Can a waterproofing membrane be installed on curved surfaces?

- Yes, a waterproofing membrane can be installed on curved surfaces. The flexibility and stretchability of the membrane allow for easy installation and adaptation to different surface shapes, including curved surfaces.

Send your message to us

Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords