Polyvinyl Chloride Punch Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

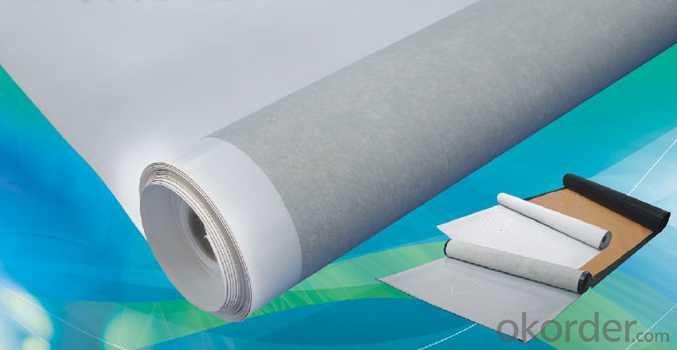

Introduction of PVC Waterproofing Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1.Excellent aging resistance. Service life of roofing material is over 30 years; service life of underground material is over 50 years.

2. High tensile strength, elongation rate is high, the heat treatment small size change.

3. Good low temperature flexibility, adapt to the environment temperature change.

4. Planting roof root resistance good permeability, can make it.

5. The perforation resistance and good resistance to impact.

6 Construction is convenient, wide width lap welding, solid object, and less reliable and pollution-free.

7. Resistance to chemical corrosion resistance, suitable for special occasions.

8. Have good plasticity, convenient edge details.

9. Convenient maintenance and low cost.

10. Light color of the surface reflection ultraviolet irradiation, coil surface west first fewer calories, low temperature.

11.Coil with good moisture diffusivity, condensate PaiShi easily, keep to the moisture, moisture easy eduction.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on concrete?

- Concrete can indeed benefit from the use of a waterproofing membrane. In fact, it is a popular technique employed to shield concrete structures from the harmful effects of water and moisture. A waterproofing membrane is a slender layer of material that is carefully placed on the concrete surface, serving as a barrier against water and moisture. This membrane can be crafted from a variety of materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. It is typically administered in either liquid or sheet form, effectively attaching itself to the surface and forming a continuous impermeable coating. This coating, in turn, prevents water from infiltrating the concrete, thereby thwarting the possibility of deterioration, cracks, and other types of damage. Waterproofing membranes are extensively employed in a wide range of concrete applications, including basements, foundations, roofs, and any other structures that are exposed to water or moisture.

- Q: Can a waterproofing membrane be used for a roof?

- Yes, a waterproofing membrane can be used for a roof. Waterproofing membranes are specifically designed to provide a barrier against water penetration, making them an ideal choice for protecting roofs from leaks and water damage. They are durable, flexible, and can be applied to various types of roofs, including flat and sloped surfaces.

- Q: Can a waterproofing membrane be used for a foundation wall damp proofing?

- Yes, a waterproofing membrane can be used for foundation wall damp proofing. Waterproofing membranes are designed to prevent the passage of water through a structure, which can help to protect the foundation wall from moisture and dampness. By applying a waterproofing membrane to the foundation wall, it can effectively damp proof the wall and prevent water infiltration.

- Q: Can a waterproofing membrane be used in planters or garden beds?

- Yes, a waterproofing membrane can be used in planters or garden beds. A waterproofing membrane is typically made of materials that are resistant to moisture and can effectively prevent water from seeping through the planter or garden bed. This can be particularly useful in situations where the planter or garden bed is made of materials that are not naturally waterproof, such as wood or concrete. By using a waterproofing membrane, you can protect the planter or garden bed from excessive water damage, which can lead to rotting, warping, or cracking. Additionally, a waterproofing membrane can also help to retain moisture within the planter or garden bed, creating a more favorable environment for plant growth. However, it is important to ensure that the waterproofing membrane used is safe for plants and does not release any harmful chemicals into the soil.

- Q: How does a waterproofing membrane perform in areas with high temperature fluctuations?

- A waterproofing membrane performs well in areas with high temperature fluctuations due to its ability to withstand expansion and contraction without compromising its integrity. The membrane's flexibility and durability allow it to adapt to the changing temperatures, preventing cracks and leaks that could lead to water damage.

- Q: Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Yes, a waterproofing membrane can be used for walkways or pedestrian bridges. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the structure and causing damage. By applying a waterproofing membrane to the surface of a walkway or pedestrian bridge, it can protect the underlying structure from water infiltration, thus increasing its durability and lifespan. This is especially important in areas prone to heavy rainfall or where the walkway or bridge is exposed to water sources such as rivers or lakes. Additionally, waterproofing membranes can also provide additional benefits such as improving slip resistance and protecting against chemicals or pollutants.

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to ensure that the manufacturer's instructions are followed regarding temperature limitations and proper installation techniques. Cold weather may affect the curing and adhesion process, so additional precautions and proper heating or insulation methods may be necessary during the application.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Basements and foundations can benefit greatly from the use of a waterproofing membrane. It is highly recommended to apply this protective layer in order to safeguard against water infiltration and moisture-related problems. Typically, the membrane is applied on the outer side of the foundation walls and basement floors, effectively creating a barrier that prevents water from permeating through the concrete. This essential measure ensures that the basement and foundation remain dry, minimizing the risk of water damage, mold growth, and structural complications. There are several types of waterproofing membranes available, including bituminous, rubberized asphalt, and liquid-applied options. This variety allows for flexibility when selecting the most suitable option according to the specific project requirements. Ultimately, installing a waterproofing membrane is a reliable means of improving the overall resilience and longevity of basements and foundations.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can reduce noise transmission.

Send your message to us

Polyvinyl Chloride Punch Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords