Polyvinyl Chloride Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

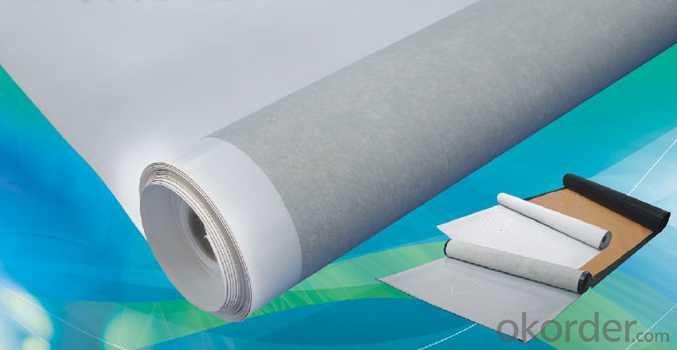

Introduction of PVC Waterproofing Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

Applicable scope

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

Cautions

1.Do not put the membrane on a pollution, water and ice ground.

2.Construcion of waterproof layer operations can't be crossed, device shall be installed on the waterproof layer, parts should be done to strengthen the basis of device and to take protective measures.

3.Do not touch the waterproof layer with thorn sharp objects after it's has been completed, don't put sundries or any additional buildings above the waterproof layer to avoid damaging it.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to handle temperature fluctuations by being flexible and resistant to thermal expansion and contraction. Temperature fluctuations can cause materials to expand and contract, which can lead to cracks, leaks, and other forms of damage. However, a waterproofing membrane is typically made from a durable and flexible material, such as PVC or EPDM, that can withstand these changes in temperature without compromising its effectiveness. When exposed to high temperatures, the membrane will expand slightly to accommodate the increased thermal energy. Conversely, when temperatures drop, the membrane will contract to maintain its integrity. This flexibility allows the membrane to adapt to the changing conditions without cracking or becoming brittle. In addition to being flexible, a waterproofing membrane is also designed to resist UV radiation from the sun. UV radiation can cause materials to deteriorate over time, leading to decreased performance and potential leaks. By incorporating UV stabilizers into the membrane's composition, it can withstand prolonged exposure to sunlight and maintain its durability even in harsh weather conditions. Furthermore, some waterproofing membranes have built-in insulation properties that help to regulate temperature fluctuations. These membranes can provide additional thermal resistance, reducing heat loss in cold weather and minimizing heat gain in hot weather. This insulation layer helps to stabilize the temperature of the underlying structure, preventing damage caused by extreme temperature changes. Overall, a waterproofing membrane is engineered to handle temperature fluctuations by being flexible, resistant to thermal expansion and contraction, and capable of withstanding UV radiation. These properties ensure that the membrane remains intact and effective in protecting the underlying structure from water damage, regardless of the surrounding temperature conditions.

- Q: Can a waterproofing membrane be used for tunnels and subway stations?

- Tunnels and subway stations can benefit greatly from the use of waterproofing membranes. These membranes are specifically designed to keep water and moisture out of structures, which makes them perfect for underground spaces like tunnels and subway stations that are prone to water infiltration. Made from high-quality materials like bitumen or synthetic polymers, these membranes have exceptional water-resistant properties. The advantages of using waterproofing membranes in tunnels and subway stations are numerous. First and foremost, they protect the structural integrity of the underground infrastructure by preventing water from seeping into the concrete or other building materials. This safeguards against corrosion and degradation, ensuring the longevity and safety of the structure. Additionally, waterproofing membranes contribute to a dry and comfortable environment within tunnels and subway stations. By preventing water accumulation, they eliminate the growth of mold, mildew, and other harmful microorganisms. They also help regulate humidity levels, which reduces the risk of condensation and water damage to equipment, electrical systems, and other components. Moreover, waterproofing membranes act as a barrier against external contaminants such as pollutants, chemicals, and gases. This is especially important in subway stations, where the concentration of pollutants from train exhaust and other sources can be higher. In conclusion, using waterproofing membranes in tunnels and subway stations is essential for ensuring the durability, safety, and comfort of these underground structures. They provide an effective solution for keeping water out, protecting the infrastructure, and maintaining a dry and healthy environment for passengers and staff.

- Q: Are waterproofing membranes resistant to chemical degradation?

- Waterproofing membranes are typically resistant to chemical degradation, providing a barrier against water and other liquids. These membranes are specifically designed with materials that have excellent chemical resistance to withstand exposure to various chemicals, including acids, alkalis, and solvents, without significant degradation or damage. This chemical resistance ensures the long-term durability and effectiveness of the waterproofing system, making it suitable for applications such as basements, roofs, and underground structures. However, it should be noted that the specific chemical resistance may vary depending on the type of waterproofing membrane and the specific chemicals it is exposed to. Therefore, careful selection of the appropriate membrane based on the intended application and the specific chemical environment is crucial. Additionally, proper installation and maintenance are essential to ensure the continued chemical resistance and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Yes, a waterproofing membrane can be used in conjunction with paint or coatings. The membrane provides a barrier against water intrusion, while the paint or coatings provide additional protection and aesthetic appeal.

- Q: Can a waterproofing membrane be used for a crawl space?

- Yes, a waterproofing membrane can be used for a crawl space. Crawl spaces are susceptible to moisture and water intrusion, which can lead to various issues such as mold growth, structural damage, and unpleasant odors. A waterproofing membrane can act as a barrier to prevent water and moisture from seeping into the crawl space. It is typically installed on the walls and floors of the crawl space, creating a watertight seal. This membrane can effectively prevent water from entering, making it an excellent solution for crawl space waterproofing. Additionally, some waterproofing membranes also have antimicrobial properties, further reducing the risk of mold and mildew growth in the crawl space.

- Q: Waterproof membrane in the escape when the full shop, empty shop, shop, shop what is the difference?

- 3, point shop paving the membrane, the membrane and the base layer with point-like bonding. Requires no less than five points per square meter of bonding. Each paste area of 100mm * 100mm. Between the point and the point should be equidistant plum-like distribution (the method can be used at the grass-roots level coating, coiling point of the membrane point coincidence).

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Indeed, nickel surfaces can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction and building ventures to safeguard surfaces against water damage and moisture infiltration. They serve as a barrier, preventing water from seeping through the surface and causing harm. Like any other metal surfaces, nickel surfaces can be vulnerable to corrosion and water-induced damage. By applying a waterproofing membrane, the nickel surface can be effectively shielded from water and moisture, thereby prolonging its lifespan and preserving its integrity. However, it is crucial to guarantee that the chosen waterproofing membrane is suitable for use on nickel surfaces. Different membranes may have distinct compatibility requirements, which is why it is advisable to consult the manufacturer or a professional for guidance on proper application and compatibility.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. Waterproofing membranes are designed to provide a barrier against moisture and water infiltration, and this includes protection against saltwater. Saltwater can be highly corrosive and can cause damage to various materials, but waterproofing membranes are typically made from materials that are resistant to the corrosive effects of salt. These membranes are often composed of materials such as reinforced PVC, modified bitumen, or EPDM rubber, which have proven to be durable and reliable in saltwater environments. Additionally, waterproofing membranes are commonly used in applications such as basements, swimming pools, and marine structures, where they are exposed to saltwater regularly. Therefore, it can be concluded that waterproofing membranes are generally resistant to salt damage and can provide effective protection against saltwater infiltration.

- Q: Does a waterproofing membrane require a topcoat or sealer?

- In order to provide extra protection and enhance its effectiveness, a topcoat or sealer is typically required for a waterproofing membrane. The membrane itself is meant to prevent water from penetrating, but applying a topcoat or sealer can further strengthen its ability to repel water and prolong its lifespan. The topcoat or sealer functions as an additional layer of defense against moisture, UV rays, and other potential causes of damage. Moreover, it can help seal any minor cracks or imperfections in the membrane, ensuring a tighter seal and reducing the risk of water infiltration. Therefore, while a waterproofing membrane can offer some level of protection independently, it is generally recommended to add a topcoat or sealer for optimal performance and longevity.

- Q: How does a waterproofing membrane handle movement or settling of the structure?

- The movement or settling of a structure can be accommodated by a waterproofing membrane in several ways. To begin with, the membrane is typically designed to be flexible and elastomeric, allowing it to stretch and move along with the structure. This flexibility prevents any cracking or tearing, ensuring that the membrane remains intact and capable of keeping water out, even when the building experiences minor shifts or settlements. Moreover, certain waterproofing membranes are equipped with built-in reinforcing materials such as polyester or fiberglass. These reinforcements provide extra strength and durability, enabling the membrane to withstand potential damage caused by movement, settling, or even structural vibrations. Furthermore, many waterproofing systems incorporate expansion joints or movement joints into the structure. These intentionally created gaps or spaces allow for natural movement. These joints are then sealed using flexible materials that are compatible with the waterproofing membrane. This ensures that the membrane can accommodate the expected movement or settling within these joints, preventing any leaks or damage to the water barrier. In conclusion, a waterproofing membrane is designed to handle movement or settling of a structure by being flexible, elastomeric, and capable of stretching without tearing. Additionally, the inclusion of reinforcements and the incorporation of expansion joints further enhance the membrane's ability to accommodate movements and maintain its effectiveness as a waterproof barrier.

Send your message to us

Polyvinyl Chloride Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords