High Strength Polypropylene Geotextile Membrane Landscape Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

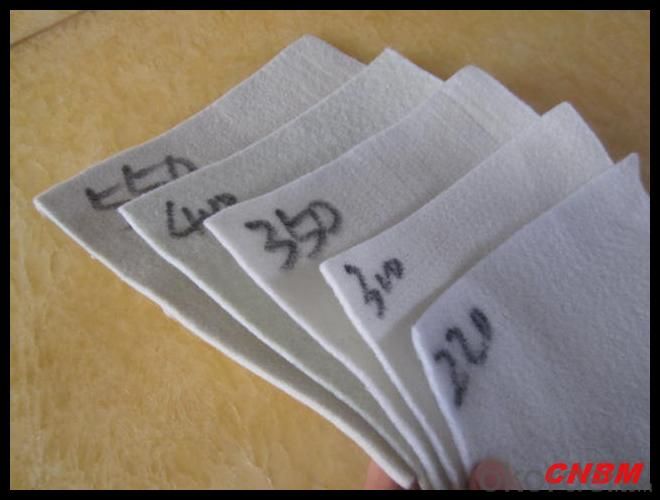

1. Polypropylene Woven Fabric Description:

Geotextile fabrics

Material:polyester fibre

Width:2-6m

Colour:white or black

Use:road ,highway,filter

Weight:100-1000g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

2. Polypropylene Woven Fabric Feature:

1. Weed suppressant and drainage control landscaping fabric

2. Spun bonded non-woven fabric – will not fray when cut

3. Easy to use

4. Environmentally friendly

5. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

6. Good alternative to Plantex® where cost is a factor

7. UV Stabilised

8. Reduces the level of watering required due to the slower rate of water evaporation

3. Polypropylene Woven Fabric Function:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

4. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Are geotextiles suitable for use in road shoulder stabilization?

- Yes, geotextiles are suitable for use in road shoulder stabilization. Geotextiles provide effective soil reinforcement and erosion control, preventing the shoulder from sinking or eroding over time. They also improve the load-bearing capacity of the shoulder, making it more durable and resistant to deformation.

- Q: Can geotextiles be used in waste containment systems?

- Yes, geotextiles can be used in waste containment systems. They are commonly employed as a barrier or liner material to prevent the escape or migration of waste materials, such as leachate, from landfills or other waste disposal sites. Geotextiles provide reinforcement, filtration, and separation properties, helping to stabilize the waste and protect the environment by reducing the risk of contamination.

- Q: Filament, preferably concrete construction

- Tianhai new material filament geotextile case analysis of water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, and weaving.

- Q: What is the use of the black network when the shop is paved?

- Black net Is a grid geotextile bar. Geotextile isolation: the use of geotextiles with different physical properties (particle size, distribution, consistency and density, etc.) of building materials (such as soil and sand, sand and gravel, soil and concrete, etc.) to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the structure of the load capacity to strengthen. 2, filament geotextile filter: When the water from the fine soil into the coarse soil layer, the use of acupuncture geotextile good permeability and water permeability, so that water through. And effectively cut off the soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 3, filament geotextile drainage: geotextile is a good water guide material, it can form a drainage channel in the soil structure, the soil structure of the excess liquid and gas excluded. 4, filament geotextile reinforcement: the use of geotextiles to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. 5, filament geotextile protection: the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external force and damage. 6, filament geotextile closure: geotextile and other materials (asphalt, plastic film) with the formation of impermeable in the soil layer. (Mainly for road resurfacing, repair, etc.).

- Q: What are the design considerations for geotextile applications?

- Some of the key design considerations for geotextile applications include the required strength, filtration properties, permeability, durability, and compatibility with the surrounding environment. Additionally, factors such as installation techniques, site conditions, and project specifications must also be taken into account during the design process.

- Q: How do geotextiles help with erosion control in coastal dunes?

- Geotextiles help with erosion control in coastal dunes by stabilizing the soil and preventing it from being washed away by wind or water.

- Q: How do geotextiles affect air quality?

- Geotextiles do not directly affect air quality as they are typically used in civil engineering applications for erosion control, filtration, and reinforcement purposes. However, the selection and installation of geotextiles can indirectly impact air quality by preventing soil erosion, which in turn reduces the release of dust particles into the air.

- Q: How do geotextiles contribute to the performance of geosynthetic tubes?

- Geotextiles play a crucial role in enhancing the performance of geosynthetic tubes by providing reinforcement, filtration, and separation functions. They help to distribute and dissipate stress and loads, preventing the tube from deformation or failure. Geotextiles also act as a filter, allowing water to pass through while preventing soil particles from clogging the tube, maintaining its hydraulic efficiency. Additionally, they separate different materials within the tube, preventing mixing and maintaining the integrity of the structure. Overall, geotextiles significantly contribute to the durability, stability, and effectiveness of geosynthetic tubes in various applications.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

Send your message to us

High Strength Polypropylene Geotextile Membrane Landscape Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords