Geotextile Fabric Reinforced High-Density Polyethylene Geomembrane for Waterproof Facing of Earth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

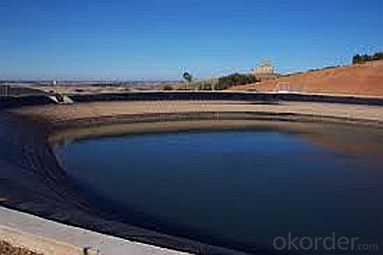

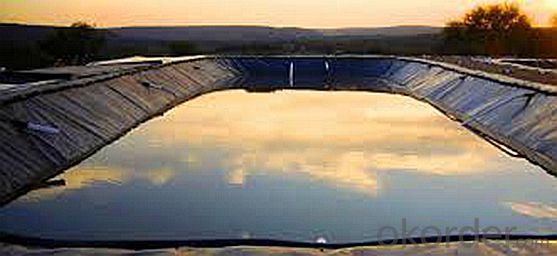

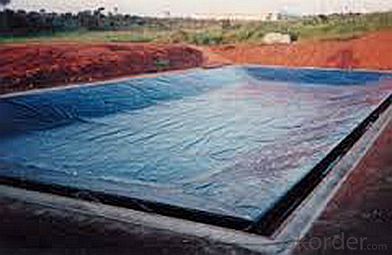

Photos:

Application

1,Environmental protection and sanitation

(landfill, ash dam for power plant,Wastewater sewage treatment plant,storage of dangerous goods , industrial waste,construction and demolition waste,toxic and harmful chemicals disposal sites,.ect.)

2,Used in seawater or freshwater breed field

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Of course, or 100 grams of Kazakhstan, the loss can be ignored manufacturers do not produce geotextile geomembrane

- Q: Can geotextile skin be connected?

- Geotextile skin can be touched. Geotextile production of raw materials is polyester fiber, polyester has been widely used in daily life. Such as clothes are also a lot of polyester material. So do not worry, geotextile is not harmful to the human body.

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of soil structures. They are effective in preventing soil erosion, enhancing drainage, and distributing loads, making them suitable for reinforcing embankments and preventing slope failures.

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles are often used as a separation and filtration layer in geogrid reinforced slopes to prevent the mixing of soil layers and ensure proper drainage, stability, and reinforcement. They help in distributing loads and reducing soil erosion, making them a valuable component in geogrid reinforced slopes.

- Q: Geotextile how to sampling

- Related methods can refer to GB-1998, can also go to our factory to purchase, to observe. My contact is the name of the registration. Free testing training! All the country's site can be shipped!

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles provide soil reinforcement in soft ground conditions by acting as a stabilizing layer. They distribute the load evenly, increasing the soil's bearing capacity and preventing excessive settlement. Additionally, geotextiles enhance soil drainage, reduce water seepage, and prevent erosion, thereby improving the overall stability and strength of the soft ground.

- Q: How do geotextiles affect soil moisture retention?

- Geotextiles can positively impact soil moisture retention by acting as a barrier that prevents excessive evaporation of water from the soil surface. They create a physical barrier that reduces water loss through evaporation, thus helping to retain moisture within the soil. Additionally, geotextiles can also facilitate water infiltration and distribution, promoting better water retention and preventing runoff. Overall, geotextiles play a crucial role in enhancing soil moisture retention and improving water management in various applications, such as agriculture, landscaping, and erosion control.

- Q: What are the advantages of using geotextiles in green roof systems?

- Geotextiles offer several advantages in green roof systems. Firstly, they act as a protective layer, preventing the roots of the vegetation from penetrating the waterproofing membrane, thereby extending its lifespan. Secondly, they help in retaining moisture, allowing the plants to access water for a longer period and reducing the need for irrigation. Additionally, geotextiles enhance drainage by facilitating the movement of excess water, preventing waterlogging and potential damage to the roof structure. Lastly, they provide stability to the growing medium, preventing erosion and promoting healthier plant growth.

- Q: Can geotextiles be used for erosion control in coastal dunes?

- Yes, geotextiles can be used for erosion control in coastal dunes. Geotextiles are permeable fabrics that can be installed to stabilize the sand and prevent erosion by trapping sediment and promoting vegetation growth. They provide an effective and sustainable solution for protecting coastal dunes from erosion caused by wind, waves, and human activities.

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Geotextile Fabric Reinforced High-Density Polyethylene Geomembrane for Waterproof Facing of Earth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords