Type 4 Cmax Non Woven Geotextile Fabric 300g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

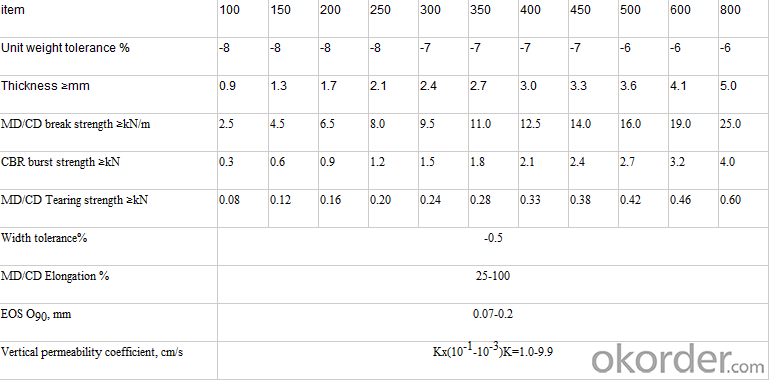

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles help with soil confinement in erosion control bags by providing a strong and permeable barrier that prevents soil particles from escaping. They act as a stabilizing agent, keeping the soil intact within the bags while still allowing water to flow through, reducing erosion and promoting vegetation growth.

- Q: What are the key considerations for geotextile installation in high wind areas?

- Some key considerations for geotextile installation in high wind areas include selecting a geotextile with a high tensile strength to withstand the force of the wind, ensuring proper anchoring and securing methods are used to prevent the geotextile from being blown away, and conducting regular inspections and maintenance to identify any damage or potential issues caused by the wind. Additionally, the design and placement of the geotextile should take into account the wind direction and intensity to minimize the risk of wind-related damage.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can significantly affect soil settlement by providing reinforcement and stabilization. These synthetic materials help distribute the loads applied to the soil, reducing settlement and preventing soil movement. They also improve drainage and filtration, allowing water to pass through the soil more easily, minimizing the potential for settlement due to water accumulation. Overall, geotextiles play a crucial role in controlling soil settlement and maintaining the stability of various structures.

- Q: What are the routine tests of geotextile geotextiles?

- The geocell is mainly the tensile strength of the tensile test lattice sheet and the peel strength of the solder joint. Geotextile according to the specific circumstances of the use of the project 1. Roadbed reinforcement, isolation is mainly tensile test tensile strength, elongation, tear strength and CBR top broken 2. Filter with the addition of these also use the vibrating screen test Equivalent pore size 3. Maintenance is mainly weight, thickness and strength

- Q: Are geotextiles suitable for use in geotextile-reinforced soil walls?

- Yes, geotextiles are suitable for use in geotextile-reinforced soil walls. Geotextiles are designed to provide reinforcement, filtration, and separation functions in various geotechnical applications, including soil walls. They help to enhance the stability and strength of the soil structure, prevent soil erosion, and improve drainage. Geotextiles also offer durability and resistance to biological degradation, making them a reliable choice for geotextile-reinforced soil walls.

- Q: How do geotextiles contribute to groundwater recharge?

- Geotextiles can contribute to groundwater recharge by acting as a filtration system, allowing water to pass through while preventing the movement of soil particles. This helps to prevent the clogging of recharge basins or infiltration trenches, ensuring a more efficient recharge of groundwater.

- Q: How do geotextiles affect groundwater flow?

- Geotextiles can either enhance or restrict groundwater flow depending on their permeability and installation method. Permeable geotextiles can allow water to infiltrate through them, facilitating groundwater recharge and promoting natural drainage. Conversely, impermeable geotextiles can prevent water from passing through, altering the natural flow of groundwater and potentially causing waterlogging or surface runoff issues. The selection and proper installation of geotextiles are crucial to ensure they positively impact groundwater flow and maintain the hydrological balance of an area.

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- The guidelines for geotextile installation in erosion control projects may vary depending on the specific project and site conditions. However, some common guidelines include conducting a thorough site assessment, properly preparing the subgrade, ensuring proper overlap and seam strength of geotextile materials, adequately anchoring the geotextile to prevent movement, and regularly inspecting and maintaining the geotextile for any damages or clogging. Additionally, following manufacturer recommendations and consulting with experienced professionals can also provide valuable insights for successful geotextile installation in erosion control projects.

- Q: What causes the geotextile aging phenomenon

- Gundam has the characteristics of the product we are all obvious, both in the highway, dams, railways and many other occasions have a very strong product features, and the performance is very outstanding, geotextile is an irreplaceable geotechnical material. Although the geotextile has unparalleled advantages, but the product is not perfect that any product has more or less problems or less, geotextile is the same, its aging problem has been with us, then in the end what causes Geotextile aging? Geotextile aging problem refers to the geotextile in the sun by the smell, temperature changes, biological erosion, chemical corrosion, moisture and other external factors, so that the geotextile strength and performance gradually weakened, loss of seepage effect. UV radiation intensity changes with the intensity of solar radiation, geotextile aging speed with the intensity of UV radiation and speed. Synthetic polymer polymer is concerned, the sun radiation is the main factor in the degradation of polymer degradation. UV radiation in the sun is the most important factor in the aging of the fabric. The ultraviolet radiation causes the polymer to produce a photooxidative decomposition reaction, especially ultraviolet light at a wavelength of 290 to 400 mPm, which has a significant decomposition effect on the polymer , Because the geotextile in the range of ultraviolet light energy is higher than the polymer chemical steamed broken the required energy, so the polymer material aging is very obvious.

Send your message to us

Type 4 Cmax Non Woven Geotextile Fabric 300g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords