Geotextile Blanc Polypropylene Staple Fiber Geotextile, High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

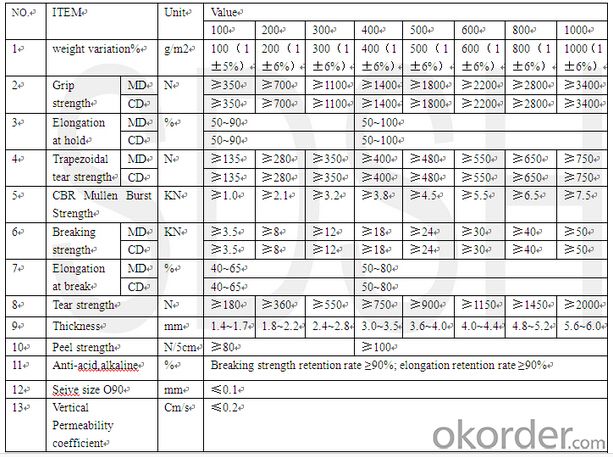

1,Brief Introduction of Polypropylene Staple Fiber Geotextile

Material:Polypropylene

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

2,Feature of Polypropylene Staple Fiber Geotextile

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

3,Package of Polypropylene Staple Fiber Geotextile

Packed in rolls or as per your request

4,Application of Polypropylene Staple Fiber Geotextile

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are often used in civil engineering projects to enhance soil stability and prevent erosion. In embankments, they can be placed between soil layers to distribute loads, improve drainage, and increase the overall strength and stability of the structure.

- Q: Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q: What are the specifications for geotextiles in landfill liner applications?

- The specifications for geotextiles in landfill liner applications typically include factors such as the material's tensile strength, puncture resistance, permeability, and ability to withstand chemical exposure. These geotextiles must meet certain standards to ensure effective containment and environmental protection in landfill projects.

- Q: Can geotextiles be used in mining reclamation projects?

- Yes, geotextiles can be used in mining reclamation projects. Geotextiles are commonly used in mining reclamation to control erosion, stabilize slopes, and promote vegetation growth. They can also help in containing and filtering pollutants from mining sites, preventing soil and water contamination.

- Q: What is the standard width of geotextile?

- Our company's production is normal 4/6 two specifications.

- Q: Can geotextiles be used for drainage?

- Yes, geotextiles can be used for drainage. They are commonly used in various drainage applications such as road construction, retaining walls, and landfills. Geotextiles help to enhance the drainage system by allowing water to pass through while preventing the loss of soil particles. They also provide filtration and separation, ensuring optimal drainage performance.

- Q: What is the length of the lap in the geotextile in the tunnel?

- General 20cm can be, I produce geotextile materials

- Q: I'm looking for the fabric that goes between gravel and the ground (for a gravel driveway).

- you can get this at wicks do it all (now focus) or any good building merchants

- Q: Geotextile use

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can indeed be used for the reinforcement of underground tunnels. Geotextiles are flexible, permeable materials that can provide support, stability, and prevent soil erosion in various civil engineering applications, including tunnel construction. They can be placed to reinforce the surrounding soil and prevent movement or collapse, enhancing the structural integrity of the tunnel. Additionally, geotextiles can also act as a drainage layer, allowing water to flow through while minimizing soil saturation, which is crucial for long-term tunnel stability.

Send your message to us

Geotextile Blanc Polypropylene Staple Fiber Geotextile, High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords