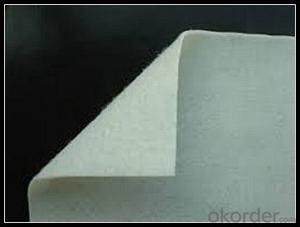

Stabilization Geotextile Fabric - Polypropylene Nonwoven Industrial Geotextile for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextile

Geotextile is a non-woven geosynthetic material, manufactured by needle-punch method. Having wonderful physical and mechanical qualities (high tensile strength, mechanical damage resistance, acid and aggressive biological environment resistance) geotextile is widely used in civil and road construction, oil-gas area, for domestic needs, melioration and landscape architecture.

Polyester fabrics is not water soluble and that is why environmental friendly.

Applications

Filtration

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining

provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

gabion structures

landfill sites.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

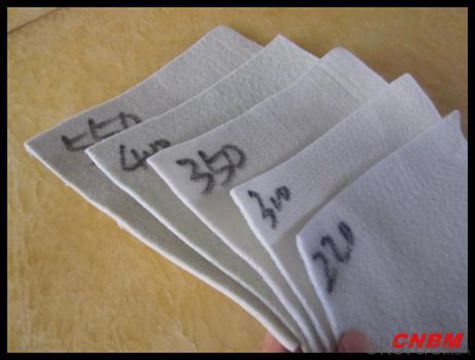

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by providing additional stability and strength to the soil. They are placed between the soil layers to prevent erosion, and their high tensile strength helps distribute the load evenly, reducing the pressure on the retaining wall. Additionally, geotextiles promote efficient drainage, preventing water buildup behind the wall, which can further weaken the soil. Overall, geotextiles act as a barrier that enhances the overall performance and longevity of retaining walls.

- Q: 5KN or 50KN

- I answered someone else on this question 1. multiply the 1.5th of the expected value of the geotextile sample by the size of the geometric cloth. 2. If you do not know the expected value, it should have a standard tensile strength range, with the tensile strength multiplied by the cross-sectional area of geotextile (thick by the width) to find the force value. 3. If you do not know, it is recommended to choose 50KN or 100KN equipment. Of course, if you need to test the geotextile was cut into a width that is particularly small, then you can use a small amount of force, but it is recommended if you choose from 5KN and 50KN election 50KN good.

- Q: How do geotextiles affect soil temperature?

- Geotextiles can have varying effects on soil temperature depending on their characteristics and application. They can act as a barrier, reducing heat transfer between the soil and the surrounding environment, leading to lower soil temperatures. However, they can also act as an insulator, trapping heat and raising soil temperatures. The specific impact on soil temperature will depend on factors such as the material composition, thickness, color, and placement of the geotextile.

- Q: What are the applications of geotextiles in road construction?

- Geotextiles have several applications in road construction, including separation, filtration, and reinforcement. They are commonly used to separate the subgrade from the base material, preventing mixing and maintaining the integrity of the road structure. Geotextiles also act as a filtration layer, allowing water to drain while preventing the migration of fine particles. Additionally, they provide reinforcement and stabilization to the road, improving its strength and durability. Overall, geotextiles play a crucial role in enhancing the performance and longevity of roads.

- Q: Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. They act as a physical barrier that inhibits weed growth by blocking sunlight and preventing weed seeds from germinating. Additionally, geotextiles allow for water and air permeability, ensuring proper drainage while still suppressing weed growth.

- Q: Is it possible to isolate permeated geotextiles and impervious geotextiles?

- Geotextile is permeable, and water, but the soil, from the filter effect, impermeable geotextile is geomembrane composite geotextile composite products, is impermeable and waterproof, I am specializing in the production of geotechnical materials,

- Q: How do geotextiles help with groundwater protection?

- Geotextiles function as a barrier or filter that helps protect groundwater by preventing the infiltration of contaminants into the underground water sources. They aid in separating different layers of soil and preventing the mixing of pollutants with the groundwater, thereby safeguarding the quality and purity of water resources.

- Q: How do geotextiles help in reinforcing soil?

- Geotextiles help in reinforcing soil by providing stability and strength to the soil structure. They act as a barrier, preventing soil erosion and enhancing the load-bearing capacity of the soil. Geotextiles distribute the applied loads evenly, reducing the stress and strain on the soil. Additionally, they allow water to drain freely, preventing water accumulation and maintaining the soil's integrity. Overall, geotextiles play a crucial role in reinforcing soil, improving its overall performance and longevity.

- Q: How are geotextiles used in civil engineering projects?

- Geotextiles are commonly used in civil engineering projects for various purposes such as soil stabilization, erosion control, drainage management, and filtration. These synthetic fabrics are placed in the soil to reinforce it, prevent erosion, filter water, separate different layers of soil, and improve the overall performance and longevity of the project. They are versatile, cost-effective, and environmentally friendly solutions that help enhance the stability and functionality of civil engineering structures like roads, embankments, retaining walls, and landfills.

- Q: How do geotextiles help in reducing the impact of heavy rainfall on soil?

- Geotextiles help in reducing the impact of heavy rainfall on soil by acting as a barrier that prevents soil erosion. They are placed on the soil surface or within the soil profile to stabilize it and improve its drainage capacity. Geotextiles allow water to pass through while retaining soil particles, preventing them from being washed away by the force of rainfall. This helps in maintaining soil structure, reducing erosion, and minimizing the loss of valuable topsoil.

Send your message to us

Stabilization Geotextile Fabric - Polypropylene Nonwoven Industrial Geotextile for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords