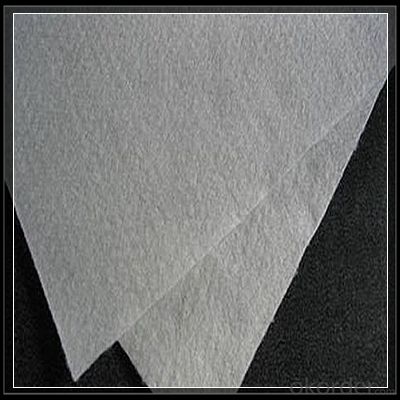

Geotextil Grk Polypropylene (PP) Geotextiles Industrial Nonwoven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Polypropylene (PP) Geotextiles

Polypropylene (PP) Geotextiles is a 100% polypropylene staple fibers needle formed, and its irregular weave mesh random to form a high strength fabric and the size of a balanced and stable. Polypropylene fiber manufactured according to special formula to resist ultraviolet rays. Encountered in the soil of ordinary non-active chemicals. Such fibers do not corrode or mildew, biologically non-degradable and resistant to insect or rodent damage. Polypropylene pH values 2-13 within the framework of the stability of。In addition, it lists the physical fit for the next performance parameters.

1: UV 500 hours after reservation 70% of

2: Tensile Strength / (KN / M) ≥ 7.5

3: elongation ≥ /% 45

4: Weight :120-140G per square meter

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in underground construction applications?

- Yes, geotextiles can be used in underground construction applications. Geotextiles are commonly used in underground construction for various purposes such as soil stabilization, drainage, filtration, and erosion control. They help to improve the overall performance and longevity of underground structures by providing reinforcement and preventing the migration of fine particles.

- Q: How do geotextiles affect construction site safety?

- Geotextiles play a crucial role in enhancing construction site safety by providing erosion control, stabilizing soil, and improving drainage. These materials prevent soil erosion, thereby reducing the risk of landslides and slope failures. Geotextiles also reinforce soil and act as a barrier against contaminants, ensuring the stability of infrastructure and preventing environmental hazards. Furthermore, they facilitate proper water drainage, preventing water buildup and reducing the risk of accidents or damage to structures. Overall, geotextiles significantly contribute to construction site safety by mitigating risks associated with soil erosion, stability, and water management.

- Q: How do geotextiles help with erosion control on slopes?

- Geotextiles provide erosion control on slopes by acting as a barrier that prevents soil erosion caused by wind and water. These textiles are permeable, allowing water to pass through while trapping soil particles, thereby stabilizing the slope and preventing erosion. Additionally, geotextiles enhance vegetation growth by retaining moisture and providing a protective layer, further reducing erosion on slopes.

- Q: GB / T-2008 has this standard on staple geotextile? What is the exact name? Know what to say thank you!

- There is the national standard, full name "staple acupuncture non-woven geotextile"

- Q: How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by providing a permeable layer that allows water and air to penetrate the soil, preventing it from becoming compacted. This allows for better drainage and aeration, promoting healthy root growth and reducing the risk of soil compaction.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoidal tear test. These methods involve applying a force to the geotextile specimen and measuring the resulting tensile strength or resistance to tearing.

- Q: Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. They are commonly used to provide stability and prevent soil erosion behind the retaining wall. The geotextiles act as a barrier, separating the soil layers and allowing water drainage while providing additional strength and stability to the structure.

- Q: Can geotextiles be used in coastal protection systems?

- Yes, geotextiles can be used in coastal protection systems. They are commonly used for erosion control, shoreline stabilization, and beach nourishment projects. Geotextiles help to prevent soil erosion, filter sediment, and promote vegetation growth, making them an effective solution for coastal protection.

- Q: How do geotextiles help with soil erosion control?

- Geotextiles help with soil erosion control by providing a physical barrier that stabilizes the soil and prevents erosion. They are specifically designed to allow water to pass through while retaining soil particles, which helps to reduce the velocity of water flow and minimize erosion. Additionally, geotextiles can increase soil strength and stability, improve vegetation establishment, and enhance overall erosion resistance in various applications such as road construction, embankments, and slope stabilization.

- Q: How are geotextiles affected by biological factors?

- Geotextiles can be affected by biological factors such as microbial degradation, plant growth, and colonization by organisms. These factors can deteriorate the material, leading to reduced strength, increased permeability, and potential failure of geotextiles in various applications.

Send your message to us

Geotextil Grk Polypropylene (PP) Geotextiles Industrial Nonwoven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords