Filament Polypropylene Geotextile for Coast Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Polypropylene geotextile for Coast Construction:

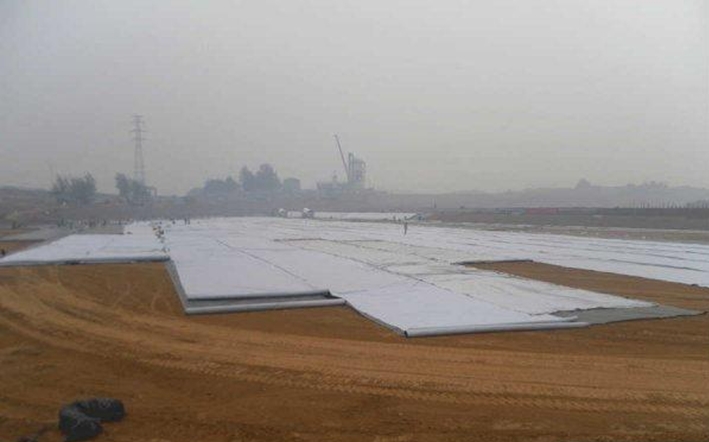

A: Subsurface drainage

B: Roadway separation

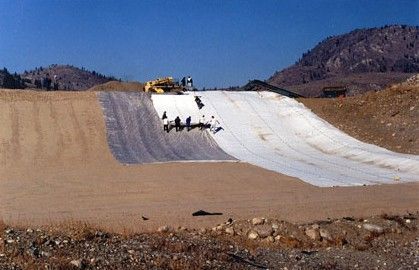

C: Hard armor underlayment

D:Asphalt overlay applications

Specification of Polypropylene geotextile for Coast Construction:

Item | Art No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

Unit weight, g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

Weight tolerance, % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness, ≥mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Break strength, ≥kN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | |

CBR burst strength, ≥kN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Tear strength, ≥kN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

Width tolerance, % | -0.5 | |||||||||||

Break elongation, % | 25-100 | |||||||||||

EOS O90, mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient, cm/s | K×(10-1-10-3)K=1.0-9.9 | |||||||||||

- Q: Geotextile above allowed to plant grass?

- Geotextile above the grass To protect the slope, then the direct use of three-dimensional vegetation network can not Well! User name is the manufacturer phone! The The

- Q: Can geotextiles be used for reinforcement in asphalt overlays?

- Yes, geotextiles can be used for reinforcement in asphalt overlays. Geotextiles act as a separator and provide reinforcement by distributing stress and preventing the mixing of different layers. They help in reducing reflective cracking and increasing the lifespan of the asphalt overlay.

- Q: What is the application of geotextile?

- Water conservancy project dam and slope protection of the filter, channel isolation, anti - seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control.

- Q: Filament, preferably concrete construction

- Tianhai new material filament geotextile case analysis of water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: How do geotextiles help with sediment retention in sediment basins?

- Geotextiles help with sediment retention in sediment basins by acting as a physical barrier that traps and holds sediment particles while allowing water to pass through. They prevent the escape of fine particles, reduce turbidity, and promote settling of sediments, thereby improving the overall effectiveness of sediment basins in sediment control and erosion prevention.

- Q: Geotextile how much money

- Specifications of different quality prices ranging from geotextiles from November last year to the current price rose too much

- Q: Geotextile construction requirements of the use of adhesive specifications

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q: What are the specifications for geotextiles in stormwater management projects?

- The specifications for geotextiles in stormwater management projects typically include factors such as the material type, weight, tensile strength, permittivity, and flow rate. The geotextiles should be made of a durable and non-biodegradable material, capable of withstanding UV exposure and chemical exposure. The weight of the geotextile is determined based on the specific project requirements and soil conditions. Tensile strength refers to the ability of the geotextile to resist tearing or stretching under load. Permittivity measures the rate at which water can flow through the geotextile, while flow rate determines the maximum water volume that can pass through the fabric per unit of time. These specifications ensure that geotextiles effectively filter and separate soil particles from stormwater, preventing clogging and maintaining the integrity of stormwater management systems.

- Q: Can geotextiles be used in retaining wall construction?

- Yes, geotextiles can be used in retaining wall construction. Geotextiles are commonly employed as a material for soil reinforcement and stabilization. They can be used in retaining walls to enhance the strength and stability of the structure by preventing soil erosion, improving drainage, and providing additional support to the soil behind the wall.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, there are several factors that need to be taken into consideration. These include the type and strength of the geotextile material, the angle of the slope, the height of the slope, the soil properties, the potential for water infiltration and drainage, the stability of the slope, and the overall aesthetic requirements. Additionally, factors such as the surrounding environment, climate, and any potential environmental impacts should also be considered during the design process.

Send your message to us

Filament Polypropylene Geotextile for Coast Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords