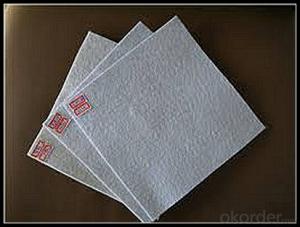

Fibra Geotextil Polypropylene Filter Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

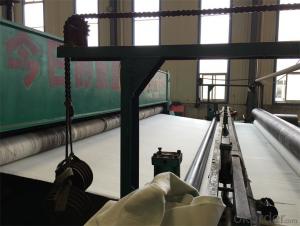

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Features

Can self-seal small cracks while forming watertight laps at the seams.

Provides a strong mechanical bond to poured concrete.

Proven effective in structures under continuous or intermittent hydrostatic pressure-up to 70m (231 ft).

Can be installed in virtually any weather condition, including freezing temperatures and damp conditions. Can be installed on green concrete without primers or adhesives.

Proven effective in both vertical and horizontal applications-i.e., backfilled and property-line walls.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the high strength to strengthen the composite geotextile

- Bujia Weaving Bugatite Rope

- Q: 300 grams of geotextile how much money a square meter

- See the requirements of the data indicators in general about 2.4 Huazhi geotextile material manufacturers

- Q: What is the latest offer for geotextile prices?

- Geotextile Product Description: Geotextile is made of polypropylene, acrylic yarn as raw material woven by the geosynthetics, widely used in water conservancy, electricity, harbors, highways, railway construction and other geotechnical engineering. Geotextiles Category: Geotextiles a wide range of ordinary geotextile refers to the permeable geotextile, also known as short wire geotextile, polyester geotextile other filament geotextile, waterproof geotextile and so on. Geotextile Price Description: There are many manufacturers of geotextiles across the country, the product offers different prices affected by the impact of raw materials and regional differences, a good product should be a penny goods. The price according to product specifications offer direct contact consultation 182 power 6686 words 2233 to find professional manufacturers to understand, product prices dynamic. Hope to help you

- Q: How are geotextiles used in slope stabilization?

- Geotextiles are commonly used in slope stabilization to reinforce and stabilize the soil, preventing erosion and landslides. They are often installed as a layer between the soil and vegetation or as a part of retaining walls. The geotextiles act as a barrier, distributing the load and improving the soil's strength, while allowing water to drain through and reducing hydrostatic pressure. This helps to maintain the stability of slopes, especially in areas prone to heavy rainfall or steep gradients.

- Q: How do geotextiles help with asphalt overlay?

- Geotextiles help with asphalt overlay by providing a stable and durable base for the new asphalt layer. They act as a barrier, preventing the mixing of the new asphalt with the existing pavement, which improves the overall strength and performance of the overlay. Additionally, geotextiles help in reducing reflective cracking and extending the lifespan of the asphalt overlay by distributing the load and reducing stresses on the pavement.

- Q: What are the advantages of using geotextiles in wetland restoration projects?

- There are several advantages of using geotextiles in wetland restoration projects. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from washing away during heavy rainfall or flooding. This helps in maintaining the wetland's structure and preventing further degradation. Secondly, geotextiles act as a barrier, preventing the migration of harmful substances such as pollutants or excess nutrients from adjacent areas into the wetland, thus protecting its ecological integrity. Additionally, geotextiles can enhance vegetation growth by retaining moisture in the soil, promoting root development, and preventing weed growth. This ultimately contributes to the overall success of wetland restoration efforts.

- Q: What are the specifications for geotextiles in civil engineering projects?

- The specifications for geotextiles in civil engineering projects typically include factors such as the material type, weight, strength, permeability, and durability. These specifications ensure that the geotextile selected is suitable for the intended application, whether it's erosion control, filtration, separation, or reinforcement. Additionally, the specifications may also cover aspects like installation requirements, testing methods, and compliance with industry standards to ensure the geotextile performs effectively and meets the project's requirements.

- Q: How are geotextiles tested for durability?

- Geotextiles are tested for durability through various methods including tensile strength testing, abrasion resistance testing, and exposure to environmental conditions such as UV radiation, temperature variations, and chemical exposure. Additionally, geotextiles may undergo puncture resistance testing and hydraulic conductivity testing to assess their long-term performance and suitability for specific applications.

- Q: What are the factors to consider when selecting geotextiles for mining applications?

- When selecting geotextiles for mining applications, several factors need to be considered. These include the strength and durability of the geotextile to withstand the harsh mining environment, the required filtration and separation properties to prevent soil erosion and maintain stability, the ability to handle high levels of water flow and drainage, and the compatibility of the geotextile with the surrounding soil and materials. Other factors may include the cost-effectiveness, ease of installation, and any specific requirements or regulations set by the mining industry.

- Q: Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. They are commonly used as a protective layer between the reservoir's base and the impermeable lining material, helping to prevent punctures and enhance the overall durability and longevity of the lining system. Additionally, geotextiles can aid in filtration and drainage within the reservoir, improving its overall performance and functionality.

Send your message to us

Fibra Geotextil Polypropylene Filter Non-Woven Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords