Sac Géotextile Polypropylene Filter Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

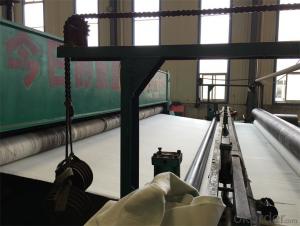

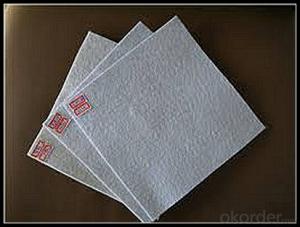

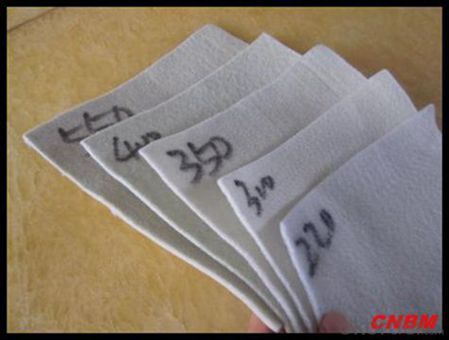

Nonwoven Geotextile 600G/M2 Geotextile Pp Non-Woven Geotextile Bags Made In China is a special kind of nonwoven geotextile because of its special manufacture method by puncturing the rolling formed layer made of randomly oriented short staple fiber. Our raw material is the top class 100% new PP(Polyproplylene) or PET(Polyester) fiber. The needle punch process involves forcibly entangling layers of loose staple fibre into three dimensional structure by sequentially punching and pulling out barbed needles through the fiber matrix, and forms a strong fabric that retains its dimensional stability, expands the serving year to all the applied project. Because of its proven track record and versatility, Needle Punched, as the most commonly used Nonwoven Geotextile, is widely used in civil and environmental engineering applications like subsurface drainage, roadway separation, railroad stabilization, erosion control, hard armor underlayment, landfill leachate collection, underground retention/detention systems, environmental protection and other projects.

Non Woven Geotextile Product Show:

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Above a geotextile one, that there is any acceptance of norms?

- Geotextile with the relevant national standard, I am specializing in the production of geotechnical materials

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile is a new type of civil artifacts material, for the construction of geotextile highway can also be Hongxiang filament geotextile, not only need to resist the complex stress under the comprehensive mechanical properties of tensile properties, etc. But also to ensure that a variety of natural factors under the influence of a long time, the overall performance does not produce significant attenuation, that is, long-term stability, high and low temperature performance, anti-aging properties. Hongxiang filament geotextile can improve the carrying capacity of the road, can improve the road in the process of using the structure of the destruction of the problem

- Q: How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by acting as a barrier that prevents erosion and soil movement. They provide reinforcement to the soil, increasing its strength and stability, while still allowing water to drain through. This prevents the loss of soil particles, helps retain moisture, and promotes healthy plant growth, ultimately reducing the risk of landslides and erosion in steep slope areas.

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- 1, geotextile cloth, high unit price. 2, plastic film poor maintenance, generally do not. 3, moisturizing cotton, grass mountain child with more.

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles contribute to erosion control on slopes by acting as a barrier that prevents soil erosion. They are typically placed on the surface of slopes to stabilize the soil and prevent the movement of sediment. The geotextiles help to reduce the velocity of water runoff, allowing it to infiltrate into the soil rather than carrying away the soil particles. Additionally, geotextiles can promote vegetation growth by providing a stable surface for plant roots to anchor, further minimizing erosion on slopes.

- Q: Can geotextiles be used in geogrid reinforced slopes?

- Yes, geotextiles can be used in geogrid reinforced slopes. Geotextiles are often used in conjunction with geogrids to enhance their performance and provide additional benefits such as filtration, separation, and erosion control. The geotextile acts as a barrier to prevent fine particles from migrating through the geogrid, while still allowing water to pass through. This combination of geotextiles and geogrids helps to improve the stability and longevity of reinforced slopes.

- Q: Can geotextiles be used in canal lining projects?

- Yes, geotextiles can be used in canal lining projects. They are often used as a lining material to enhance the stability and longevity of canals. Geotextiles help to prevent erosion, control seepage, and provide reinforcement to the canal structure.

- Q: Why the durability of filament geotextile is relatively strong

- The reason for raw materials

- Q: What are the limitations of geotextiles?

- Some limitations of geotextiles include their vulnerability to UV degradation, limited effectiveness in high flow conditions, and potential for clogging with fine particles. Additionally, geotextiles may not be suitable for certain applications where high strength or puncture resistance is required.

Send your message to us

Sac Géotextile Polypropylene Filter Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords