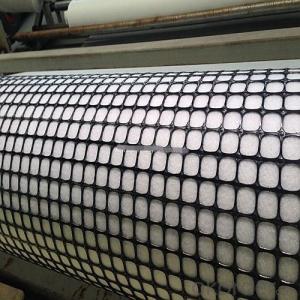

Polyester Woven Geogrids - PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

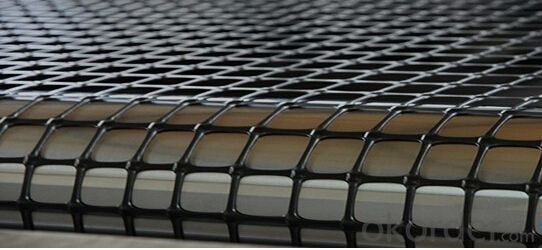

1. Introduction of PP Biaxial Geogrid

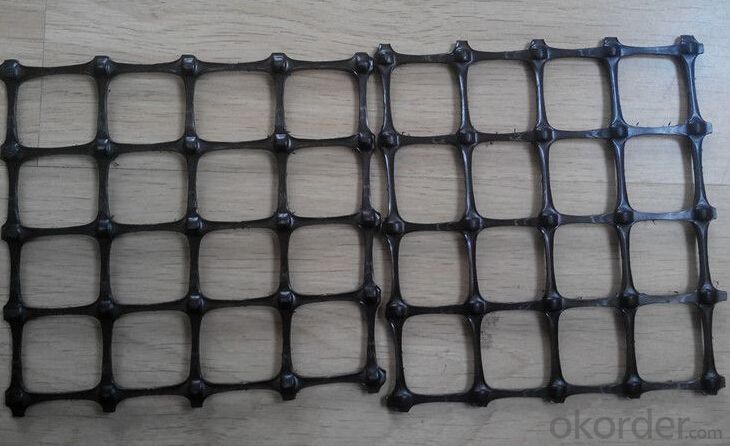

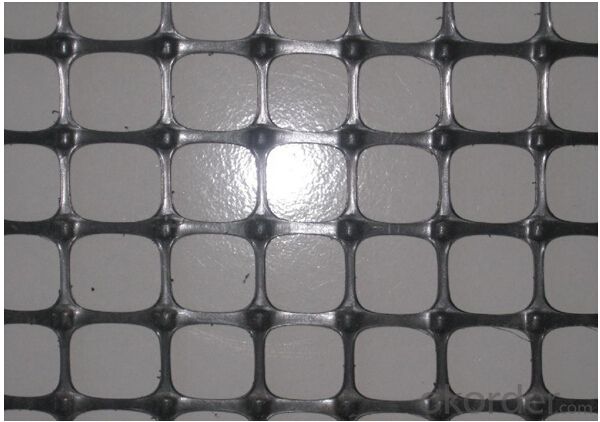

PP Biaxial Geogrid is manufactured from Polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill.

2. Features of PP Biaxial Geogrid

High tensile strength at both longitudinal and transverse direction

3. Application of PP Biaxial Geogrid

Soft foundation reinforcing for highway, railway, slope protecting projects, landfill sites.

4. Technical Data and Specification of PP Biaxial Geogrid

Property | Test Method | TGSG 15-15 | TGSG 20-20 | TGSG 30-30 | TGSG 40-40 | |

Ultimate tensile strength(1) (kN/m) | MD |

ASTM D 6637 | 15 | 20 | 30 | 40 |

CD | 15 | 20 | 30 | 40 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Tensile strength at 2 % elongation (kN/m) | MD | 5 | 7.5 | 10.5 | 14 | |

CD | 5 | 7.5 | 10.5 | 14 | ||

Tensile strength at 5 % elongation (kN/m) | MD | 7 | 14 | 21 | 28 | |

CD | 7 | 14 | 21 | 28 | ||

Minimum Carbon Black | % | ASTM D 4218 | 2 | |||

Dimensions

Roll Length(m) | 100/50 |

Roll Width(m) | 2/3.9/3.95 |

5. Loading Quantity for one 40HC.

TGS15-15, 300rolls, 59250m2

TGS20-20, 220rolls, 43450m2

TGS30-30, 144rolls, 28440m2

TGS40-40, 100rolls, 19750m2

6. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

4) Can you provide free samples?

Yes, we can supply but express fees are usually on buyer's account.

- Q: How do geogrids improve the stability of channel linings?

- Geogrids improve the stability of channel linings by enhancing soil reinforcement and preventing erosion. They act as a strong and flexible reinforcement material that helps distribute the loads and stresses applied to the channel lining. By interlocking with the surrounding soil, geogrids increase the overall tensile strength and shear resistance of the structure, preventing it from shifting or collapsing. Additionally, geogrids provide a barrier against erosion by stabilizing the soil particles and preventing them from being washed away by flowing water, thus maintaining the integrity of the channel lining.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically involve preparing the subgrade, ensuring proper anchoring and overlap of the geogrid, and compacting the fill material. Additionally, the specifications may include guidelines for the required geogrid strength, aperture size, and roll width, as well as the recommended installation techniques and equipment. It is essential to follow the manufacturer's instructions and any relevant industry standards for a successful geogrid installation.

- Q: What are the advantages of using geogrids in ground reinforcement?

- There are several advantages to using geogrids in ground reinforcement. Firstly, geogrids provide increased stability and load-bearing capacity to the soil, making them beneficial for areas with weak or unstable ground. Secondly, they help prevent soil erosion, as the geogrids act as a barrier that holds the soil in place. Additionally, geogrids can reduce construction costs by allowing for the use of locally available, less expensive fill materials. They also facilitate faster construction times, as they are easy to install and require minimal excavation. Overall, geogrids offer a cost-effective and efficient solution for ground reinforcement projects.

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Some of the design drawings, the specification seems to be unable to find, which is related to the location of longitudinal flexible drainage pipe

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- Your expression is not clear,

- Q: How do geogrids improve the performance of geosynthetic-reinforced retaining walls?

- Geogrids improve the performance of geosynthetic-reinforced retaining walls by providing tensile reinforcement to the soil, increasing its overall strength and stability. They help distribute the lateral forces exerted on the wall, preventing potential wall failure or deformations. Additionally, geogrids increase the bearing capacity of the soil, allowing for the construction of taller and steeper walls.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on factors such as the quality of the material, the environmental conditions they are exposed to, and the level of stress they experience. However, geogrids are generally designed to have a lifespan of 20 to 50 years.

- Q: What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification typically include various parameters such as tensile strength, junction strength, aperture size, creep behavior, and durability. These tests are conducted according to industry-recognized standards such as ASTM D6637, ISO 10319, and GRI-GG2. The certification process ensures that geogrids meet the required performance criteria and can be used effectively in geotechnical applications.

- Q: What is geogrid, what is the role?

- Glass fiber geogrid is a way used to enhance, reinforcement, reinforcement of excellent geosynthetic materials of soft soil subgrade. And in the treatment of asphalt pavement reflection crack applications, has become the indispensable materials. The product is made of high strength alkali free glass fiber through international advanced knitting process made of mesh substrate. Semi rigid products by surface coating processing and made with warp and weft two-way high tensile strength and low elongation, and high temperature resistance, low temperature, aging resistance, corrosion resistance and other excellent properties, is widely used in the asphalt pavement, cement concrete pavement and subgrade reinforcement and railway roadbed, dam slope protection, airport runway, sand project.

- Q: Can geogrids be used in coastal erosion control?

- Yes, geogrids can be used in coastal erosion control. Geogrids are commonly employed in coastal areas to stabilize soil and prevent erosion by reinforcing the ground and enhancing its resistance to erosion forces such as waves and currents. They provide effective erosion control measures by acting as a barrier against soil movement and preventing the loss of valuable coastal land.

Send your message to us

Polyester Woven Geogrids - PP Biaxial Geogrid for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords