Woven Polyester Geogrids - Polypropylene Triaxial FRP PP Quaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

Four axial geogrid

stable triangular structure

Withstand loads in more directions

PP Quaxial Geogrids

Junction efficiency

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

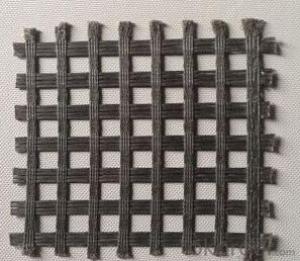

Geogrid Show:

- Q: Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are commonly used in landfill capping systems to provide reinforcement and stability to the cover materials. They help distribute loads and reduce stress on the cover system, improving its integrity and performance.

- Q: What are the installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, mechanical connection, and soil confinement. Direct placement involves laying the geogrid directly on the ground and securing it with stakes or pins. Mechanical connection involves connecting the geogrid to other materials, such as retaining walls or slopes, using connectors or anchor systems. Soil confinement involves placing the geogrid within a layer of soil to improve its stability and strength. The specific installation method used depends on the specific project requirements and conditions.

- Q: Production of geotextile manufacturers which good

- Needle punched nonwoven fabric and PE film composite geotextile:A specification film cloth, a cloth film two, maximum width of 4.2 meters is the main raw material to use acupuncture non-woven polyester staple fiber, PE film by composite, is mainly used for seepage control, applicable to rail, highway, tunnel, subway, airport project. Geotextile manufacturers can choose Wo environmental protection

- Q: How to distinguish from the appearance of plastic geogrid and fiberglass geogrid

- This is a direct look at the different products.

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving synthetic fibers together to create a strong and flexible grid structure. This type of geogrid has high tensile strength and is commonly used for soil stabilization and reinforcement. On the other hand, a non-woven geogrid is made by bonding synthetic fibers together without the use of weaving. It is typically a lower-cost option and is commonly used for filtration and separation applications. Overall, the main difference between the two is the manufacturing process and the intended use.

- Q: What is the single geogrid 60kN/m

- Unidirectional geogrid, the tensile strength is not less than 60 kn per meter

- Q: Fiberglass grille width

- Geogrid, fiberglass geogrid

- Q: What is the effect of cyclic loading on geogrid behavior?

- Cyclic loading on geogrid behavior can have detrimental effects, such as increased deformation and reduced strength over time. This repeated loading and unloading can lead to progressive damage and degradation of the geogrid, compromising its ability to provide reinforcement and stabilization. Therefore, it is important to consider the potential impact of cyclic loading when designing and implementing geogrids in construction projects.

- Q: What is geogrid, what is the role?

- To enhance the problemGlass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce reflection crack.

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- Bidirectional welding plastic top net, high strength spiral rib steel wire grid model, integrated 3D Geomat, high strength geogrid, geocell, engineering fiber, geotextile composite geomembrane, whichincludesimportedwetthinfeltproductionline engineering materials used in underground coal mine

Send your message to us

Woven Polyester Geogrids - Polypropylene Triaxial FRP PP Quaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords