Geocells for Erosion Control - Uniaxial Plastic Geogrid CE Certificate Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Uniaxial Plastic Geogrid descriptions:

It is is a smooth high density proethylene(HDPE) Geogrid manufactured with the highest quality . This product is used in applications that require excellent chemical resisitance and endurance properties.

Features of Uniaxial plastic Geogrid :

High strength , Good flexibility, anti-aging, resisting acid and Alkaline.

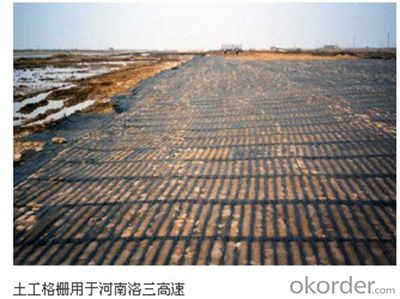

Usage of Uniaxial Plastic Geogrid :

Make reinforcement for various kinds of soil foundation enhance and improve bearing ability if the roadbed .make reinforcement for retaining wall, steep slope, dam and bridge abutment under stress status for long term thus to improve quality and prolong service life of the project .

Specification of the Uniaxial Geogrid

TGDG35 TGDG50 TGDG80 TGDG110 TGDG120

Width : <= 2.5m

Length : 50—100m

Color : black

Packaging : Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods: within 15 days after receiving the deposit

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids have specific maintenance requirements. They should be inspected regularly for any signs of damage or deterioration, such as tears, fraying, or disintegration. If any issues are found, appropriate repairs or replacements should be made promptly to ensure the geogrid's effectiveness. Additionally, geogrids should be kept clean and clear of any debris or vegetation that could impact their performance.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- For example, geotextile, geomembrane, soft water pipes, etc.. According to the direction of the water flow, the coefficient of permeability of the geotextile is measured

- Q: How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and increasing the tensile strength of the soil. They act as a barrier, distributing the load and preventing soil erosion. This reinforcement helps to prevent slope failure and ensures the long-term stability of the slope.

- Q: Who has the "highway geosynthetics geogrid" specification

- The first part of Geogrid

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, preventing erosion and minimizing settlement. They distribute loads efficiently, increasing the overall strength of the embankment and ensuring long-term stability for pipeline crossings.

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. Geogrids are designed to provide reinforcement and improve the strength and stability of soil, especially in areas with soft or weak soils. By increasing soil stiffness and redistributing loads, geogrids help to prevent soil settlement, improve bearing capacity, and enhance overall stability.

- Q: How do geogrids enhance the performance of mechanically stabilized earth walls?

- Geogrids enhance the performance of mechanically stabilized earth walls by providing reinforcement to the soil mass, increasing its overall tensile strength, and reducing lateral movement. This helps to prevent soil erosion, improve stability, and increase the load-bearing capacity of the wall, making it more resilient and durable.

- Q: How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- And the glass fiber grid, but because of the large deformation of the plastic grille and glass fiber grille is mainly suitable for the cause of the road engineering, and the emergence of a new type of steel plastic composite geogrid

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth walls for bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth walls for bridge abutments. Geogrids are commonly used to enhance the stability and load-bearing capacity of soil structures, such as retaining walls and bridge abutments. By providing tensile strength and distributing loads, geogrids help prevent soil erosion and maintain the integrity of the structure, making them an effective solution for reinforcing mechanically stabilized earth walls in bridge abutments.

- Q: Are geogrids suitable for use in ground reinforcement for residential developments?

- Yes, geogrids are suitable for use in ground reinforcement for residential developments. Geogrids provide effective soil stabilization and reinforcement, enhancing the stability and load-bearing capacity of the ground. They are durable, cost-effective, and can be easily installed, making them a practical choice for residential projects.

Send your message to us

Geocells for Erosion Control - Uniaxial Plastic Geogrid CE Certificate Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords