Polyester Filament Woven Geotextile PET Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

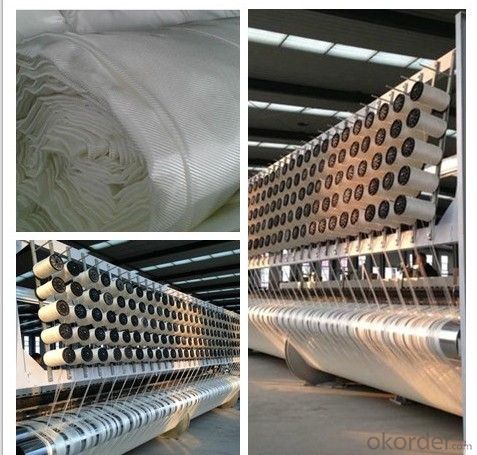

Polyester Woven Geotextile

Polyester Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Polyester Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Polyester Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Polyester Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

Polyester Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are generally designed to be resistant to punctures and tears. They are made from strong materials that provide durability and can withstand external forces, making them an effective solution for various applications requiring such resistance.

- Q: Are geotextiles used in landfill construction?

- Yes, geotextiles are commonly used in landfill construction. They serve several purposes such as preventing soil erosion, stabilizing slopes, and facilitating drainage. Geotextiles also help to separate different layers of soil and prevent the mixing of waste materials with the surrounding soils.

- Q: What are the key considerations for geotextile installation in corrosive environments?

- The key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper installation techniques to minimize exposure to corrosive elements, and regular inspection and maintenance to monitor for any signs of corrosion or damage. Additionally, it is important to consider the long-term performance and durability of the geotextile in the specific corrosive environment to ensure its effectiveness and longevity.

- Q: 15 km highway how much geotextile

- Depends on how wide your road, come to the square, you know about how much. Manufacturers produce geotextiles

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include pore size, permeability, thickness, and the nature of the soil being filtered.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been proven to provide effective soil stabilization, erosion control, and reinforcement in areas prone to seismic activity. They can help mitigate soil liquefaction, slope instability, and ground settlement issues, making them a suitable choice for construction projects in seismic zones.

- Q: What are the different geotextile specifications and standards?

- There are several geotextile specifications and standards that are commonly used in the industry. Some of the main ones include ASTM D6388, ASTM D4355, and ASTM D4491. These standards cover various aspects of geotextiles such as material properties, test methods, and installation requirements. Additionally, there are also specific specifications and standards set by various government agencies and organizations for geotextiles used in specific applications, such as road construction or erosion control. Overall, these specifications and standards help ensure the quality and performance of geotextiles in different applications.

- Q: Can geotextiles be used in green roof drainage systems?

- Yes, geotextiles can be used in green roof drainage systems. Geotextiles are commonly used as a filtration layer to separate the drainage material from the growing medium in green roofs. They help to retain moisture, prevent clogging, and enhance the overall performance of the drainage system.

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

Send your message to us

Polyester Filament Woven Geotextile PET Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords