5086 Aluminum Coil Polyester Oil Painted for Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

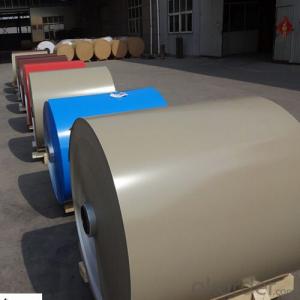

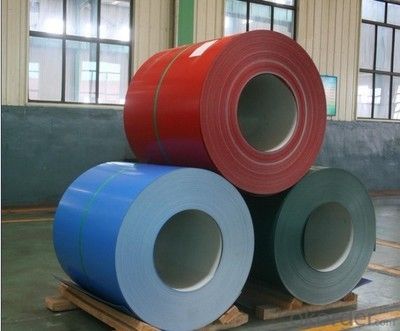

Structure of Aluminium Polyester Oil Painted for Glass Wall Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Polyester Oil Painted for Glass Wall:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Polyester Oil Painted for Glass Wall:

Aluminium Polyester Oil Painted for Glass Wall Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different protective coatings available for aluminum coils?

- There are several different protective coatings available for aluminum coils. Some common options include: 1. Polyester Coating: This is a versatile coating that provides excellent weather resistance and color retention. It is commonly used in outdoor applications where the aluminum coils may be exposed to harsh weather conditions. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings are known for their exceptional durability and resistance to fading, chalking, and chemical exposure. They are often used in architectural applications where a long-lasting and high-performance finish is required. 3. Epoxy Coating: Epoxy coatings offer excellent adhesion and corrosion resistance. They are frequently used in industrial settings, such as in the manufacturing of appliances or automotive parts. 4. Acrylic Coating: Acrylic coatings provide good weatherability and UV resistance. They are commonly used in interior applications or in environments with mild outdoor exposure. 5. Polyurethane Coating: Polyurethane coatings offer a high level of impact resistance and flexibility. They are often used in applications where the aluminum coils may be subject to physical stress or deformation. 6. Ceramic Coating: Ceramic coatings provide superior heat resistance and thermal stability. They are commonly used in automotive applications or in environments with high-temperature exposure. Overall, the choice of protective coating for aluminum coils depends on the specific application requirements, such as weather resistance, durability, or chemical resistance. It is important to consider the environmental conditions and performance expectations when selecting the appropriate coating for aluminum coils.

- Q: Can aluminum coils be used in aerospace applications?

- Yes, aluminum coils can be used in aerospace applications. Aluminum is a widely used material in the aerospace industry due to its lightweight and high strength-to-weight ratio. Aluminum coils are often used in the construction of aircraft structures, such as fuselages, wings, and landing gear, as well as in heat transfer and cooling systems. Their excellent corrosion resistance and high thermal conductivity make them suitable for various aerospace applications. Additionally, aluminum coils can be easily formed and fabricated, allowing for complex shapes and designs required in aerospace components.

- Q: What is the difference between aluminum coils and aluminum sheets?

- Aluminum coils and aluminum sheets are both made from the same material, which is aluminum. However, there are some key differences between the two. One major difference is their form and shape. Aluminum coils are typically long, continuous pieces of aluminum that are wound into a coil shape. They are often used in industries such as construction, automotive, and HVAC for applications such as roofing, insulation, and air conditioning systems. On the other hand, aluminum sheets are flat pieces of aluminum that come in various sizes and thicknesses. They are commonly used in industries like aerospace, transportation, and packaging for applications such as aircraft parts, automotive body panels, and food packaging. Another difference is their manufacturing process. Aluminum coils are produced by a process called continuous casting, where molten aluminum is continuously poured into a mold and then cooled and solidified into a coil shape. This process allows for the production of long, continuous coils. Aluminum sheets, on the other hand, are typically produced through a rolling process. The aluminum is passed through a series of rollers that progressively reduce its thickness until the desired sheet thickness is achieved. This process allows for the production of flat sheets with specific thicknesses. Furthermore, the uses and applications of aluminum coils and sheets also differ. Due to their coil shape, aluminum coils are commonly used in applications that require long continuous lengths, such as roofing or HVAC systems. Aluminum sheets, with their flat shape, are often used in applications where a flat surface is needed, such as in the manufacturing of panels or components. In summary, the main difference between aluminum coils and aluminum sheets lies in their form, manufacturing process, and applications. Coils are long, continuous pieces of aluminum produced through continuous casting, while sheets are flat pieces produced through rolling. The choice between coils and sheets depends on the specific requirements of the application.

- Q: This question asks for methods to check the quality of aluminum coils.

- <p>To inspect aluminum coils for quality, follow these steps: Visually inspect for any surface defects like scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Check the hardness and tensile strength using appropriate testing equipment. Examine the coil's flatness and straightness to avoid issues in further processing. Assess the surface roughness and cleanliness, as these can affect the coil's performance. Conduct a chemical composition analysis to confirm the alloy type and purity. Perform a magnetic particle inspection or ultrasonic testing to detect any internal defects. Finally, ensure the coil meets the required mechanical properties and specifications as per industry standards.</p>

- Q: What house hold materials contain 100% pure aluminum. or where can i buy it. im making thermite, which ive made before so don't say, its dangerous don't do it, but do i need 100% pure aluminum or will some aluminum alloy with like 90% aluminum work?????

- Aluminum foil is your best bet. According the the Reynold's wrap web site, their foil is 98.5% aluminum.

- Q: Are there any limitations to the minimum coil length of aluminum coils?

- Yes, there are limitations to the minimum coil length of aluminum coils. The minimum coil length is determined by various factors such as the manufacturing process, equipment capabilities, and the intended use of the coils. One limitation is the size and capacity of the manufacturing equipment. Most coil production lines have a minimum length requirement to ensure efficient operation and to prevent damage to the coils during the manufacturing process. If the coil is too short, it may not be properly processed or handled by the equipment, leading to production issues or product defects. Another limitation is the intended use of the coils. Certain applications may require a minimum coil length to meet specific requirements or to ensure optimal performance. For example, in industries such as construction or automotive, coils are often used to make components or structures that have specific length requirements. In such cases, the minimum coil length is determined by the specifications of the end product. Additionally, handling and transportation considerations also play a role in determining the minimum coil length. Coils that are too short may be more difficult to handle, transport, or store, making them less practical or cost-effective. In summary, the minimum coil length of aluminum coils is subject to limitations imposed by manufacturing equipment capabilities, intended use, and practicality in terms of handling and transportation. These limitations ensure efficient production processes, adherence to product specifications, and practicality in the overall supply chain.

- Q: I bought a house that is older with aluminum windows, and the last owner did not seem to clean them for quite some time. The aluminum frames are a silvery milky white color and my neighbors that have the same windows look like chrome. I have brushed these windows with scrub brushes and green scouring pads even aluminum wheel cleaner, now my frame is a clean milky grey color, it just isnt polished like my neighbor has it, his is like chrome. I have tried silver polishes and this doesn't remove the grey film either - i need something stronger. Can anyone help???

- Fistly give them a good clean, next get some marine polish-I've seen it at Halfords, and buff your window frames to a glossy shine.

- Q: Can aluminum coils be used in electrical cables?

- Electrical cables can indeed incorporate aluminum coils. Aluminum is widely utilized as a material for electrical conductors due to its exceptional electrical conductivity and comparatively lower cost when compared to copper. Its usage is particularly prominent in power transmission and distribution cables that necessitate long-distance transmission. Overhead power lines and underground cables often employ aluminum coils. However, it is crucial to acknowledge that aluminum possesses a lower tensile strength than copper, requiring careful design and manufacturing of the cables to ensure sufficient mechanical strength. Furthermore, achieving the same electrical performance with aluminum conductors necessitates larger cross-sectional areas compared to copper, potentially resulting in slightly larger cable sizes.

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- You should use the eddy current displacement sensor KD2306 if the object is aluminum,

- Q: What is the role of aluminum coils in the construction of aircraft?

- The significance and versatility of aluminum coils in aircraft construction cannot be overstated. Aluminum, with its exceptional properties like lightweightness, durability, and resistance to corrosion, is the preferred material for manufacturing aircraft. In particular, aluminum coils find extensive use in various aircraft components such as the fuselage, wings, and structural elements. One of the primary functions of aluminum coils is to impart structural strength while keeping the aircraft lightweight. By incorporating aluminum coils, aircraft manufacturers can effectively reduce the overall weight of the aircraft, leading to improved fuel efficiency and increased payload capacity. This holds immense importance in aviation, where even the slightest reduction in weight can have a substantial impact on performance and operational costs. Furthermore, aluminum coils play a pivotal role in enhancing the aerodynamic design of the aircraft. These coils are employed to shape the wings and other aerodynamic surfaces, enabling superior airflow and decreased drag. The flexibility of aluminum coils empowers engineers to create intricate, curved shapes that optimize the aircraft's aerodynamic performance, resulting in enhanced maneuverability and reduced fuel consumption. Another critical aspect of aluminum coils in aircraft construction is their ability to resist corrosion. Aluminum naturally forms a protective oxide layer when exposed to air, rendering it highly resistant to corrosion. This property proves indispensable in ensuring the aircraft's longevity and structural integrity, especially when subjected to harsh environmental conditions like high altitudes or coastal regions. Moreover, aluminum coils find application in the manufacturing of heat exchangers, crucial components of the aircraft's cooling and ventilation systems. These coils efficiently transfer heat either to or from the air, depending on the requirements of the system, enabling effective temperature control within the aircraft's cabin and engine compartments. In conclusion, the role of aluminum coils in aircraft construction is indispensible. They provide structural strength, contribute to aerodynamic efficiency, offer corrosion resistance, and facilitate efficient heat exchange. The utilization of aluminum coils enables the development of high-performance, reliable, and fuel-efficient aircraft that are essential for modern aviation.

Send your message to us

5086 Aluminum Coil Polyester Oil Painted for Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords