PLC Control Non-negative Pressure Water Supply Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PLC Control Non-negative Pressure Water Supply Equipment

1.Structure of PLC Control Non-negative Pressure Water Supply Equipment Description

PLC Control Non-negative Pressure Water Supply Equipment is a high efficient water facility has characters of easy installation,saving space, water pool is not required.The pump energy efficient, using I mm converter speed control valve control over a large number of energy saving, the elimination of the high level of secondary pollution of water tanks,water tank eliminates the need to wash the cost and trouble,Water Pump achieve soft-start, start on the grid to reduce the impact of pumps to extend life.

2.Main Features of the PLC Control Non-negative Pressure Water Supply Equipment

Water Supply: Urban water supply, boiler or condensate system, water filtering and distribution, water to water district, in charge of pressurized, high-rise building pressurization.

Industrial boosting: process water system, cleaning system, high pressure washing system, fire system.

Industrial liquid conveying: cooling and air conditioning systems, boiler feed and condensate systems, machine matching, acid and alkali.

Water Treatment: Industrial circulating system and processing system, environmental protection water treatment and infiltration analysis system, Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, swimming pool

Irrigation: Agriculture irrigation and dewatering, sprinkler irrigation, drip irrigation.

3.PLC Control Non-negative Pressure Water Supply Equipment images

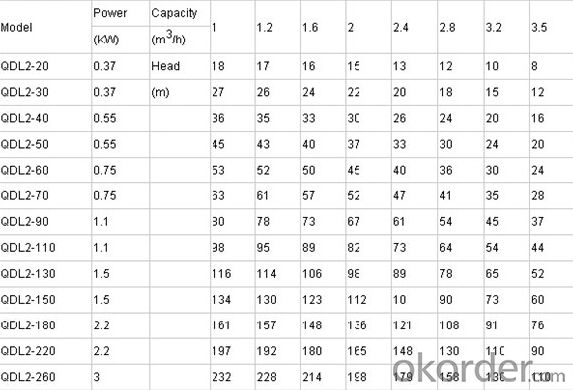

4.PLC Control Non-negative Pressure Water Supply Equipment Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: What is the difference between swashplate pump and crankshaft pump?

- Piston pump: valve plate, valve plate, piston, piston ring, crankshaft, connecting rod and so on, all belong to its spare parts.Piston pump working principle: by the piston in the pump cylinder for reciprocating movement to suction and remove liquid.

- Q: What is the name of the day pump and ground pump? Specific introduction

- Day pumpDay pump is called "day pump", the main reason is that it can deliver concrete to a certain height, make up for other concrete pump transportation shortage. Compared with other concrete pumps, the pump has its own boom, and the concrete can be transported without the use of artificial cloth. It is very convenient for use. At present, China's longest boom pump is 101 meters, which means that 101 meters under the floor can be completed with the help of day pump concrete delivery. In addition, the pump is equipped with a chassis, so compared with the ground pump, it can walk independently, moving very convenient, you can quickly move from one site to another location.

- Q: What's the pump? Where can I use it?

- Working principleIt transfers mechanical energy or other external energy of the prime mover to the liquid, increasing the energy of the liquid. Before the pump starts, the pump shell is filled with the liquid to be transported; after starting, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate. Under the influence of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, and leaves the outer edge of the impeller at high speed to enter the volute pump shell. In the spiral case, the liquid slows down due to the gradual enlargement of the flow passage, and the part of kinetic energy is converted to static pressure, and finally flows into the exhaust pipe at higher pressure and is sent to the required place. When the liquid flows from the center of the impeller to the outer edge, a vacuum is formed at the center of the impeller. As the pressure at the upper level of the tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller. Visible, as long as the impeller continues to rotate, the liquid will continue to be inhaled and discharged.

- Q: The distance from the pump button to the ground

- A button is arranged on the surface of the fire hydrant button, and when the fire hydrant is started, the press button can be pressed directly, and the red starting indicator light of the fire hydrant button is on

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- When the pump is working, the liquid at the inlet of the impeller, due to a certain vacuum pressure will produce steam, the vaporization of the bubble in liquid particles under the impact of movement, the impeller and other metal surface erosion, thereby damaging the impeller and other metal

- Q: What kind of motor does the hydraulic pump need?

- Hydraulic pump is a power component of hydraulic system. It is driven by an engine or an electric motor. It draws oil from the hydraulic tank to form a component of the pressure oil which is sent to the actuating element. Hydraulic pump according to the structure is divided into gear pumps, piston pumps, vane pumps and screw pumps.

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Important equipment for deep well water extraction. When in use, the whole unit dives into the water. The extraction of groundwater to the surface is water, mine rescue, industrial cooling, irrigation, water lifting, ship ballast, also can be used in fountain landscape, hot water submersible pump for hot spring bath, but also can be applied to the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects. The utility model is mainly used for farmland irrigation and water for human and livestock in mountain areas, and can also be used for central air conditioning cooling, heat pump units, cold pump units, cities, factories, railways, mines and site drainage. General flow can reach (10m3~650m3) per hour, head up to 1500 meters.

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 3. master the operating rules of the pump operation, and make sure the pump position is reasonably determined. Do a good job of site investigation, find out, pay attention to.4. master the working principle and basic technical parameters of the delivery pump. Obey the command of production dispatcher to ensure the completion of production tasks.5., according to the number of tanker at the scene, determine the pumping speed, in order to ensure the continuity of pouring.6. normal pumping, the discharge rate should be uniform, to prevent uneven discharge, resulting in pressure pipe gas plug, and thus lead to pipe or pipe explosion accident.

- Q: Working principle and structure of external gear pump

- When the meshing teeth on one side of the suction chamber are gradually separated, the volume of the suction chamber is increased, and the pressure is lowered, and the liquid in the suction pipe is sucked into the pump; the suction liquid is divided into two parts to be pushed into the discharge chamber by the gear in the alveolus. When the liquid enters the exhaust chamber, the liquid is squeezed and discharged from the exhaust chamber into the discharge pipe because the teeth of the two gears are continuously engaged. The driving gear and the driven gear keep rotating, and the pump can continuously inhale and discharge the liquid. The pump body is equipped with a safety valve, when the discharge pressure exceeds the required pressure, the delivery liquid can automatically open the safety valve, so that the high-pressure liquid returns to the suction pipe.

- Q: How can I buy a pump?

- 2, must meet the characteristics of the media requirementsFor the delivery of flammable, explosive, toxic or valuable medium pump, requiring reliable sealing shaft or the use of non leakage pump, such as magnetic drive pumps (without shaft seal, using isolated magnetic indirect drive).For the transmission of corrosive medium pumps, convection components are required to use corrosion-resistant materials, such as fluorine plastic corrosion resistant pump.For conveying pumps containing solid particles, wear resistance materials shall be adopted in convection parts, and clean liquid shall be used for shaft seal when necessary.

Send your message to us

PLC Control Non-negative Pressure Water Supply Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords