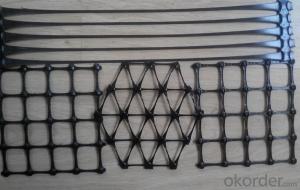

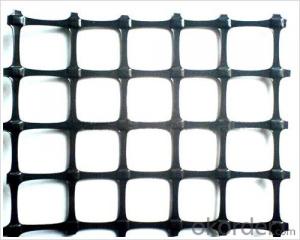

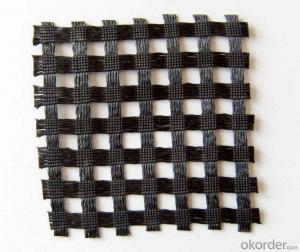

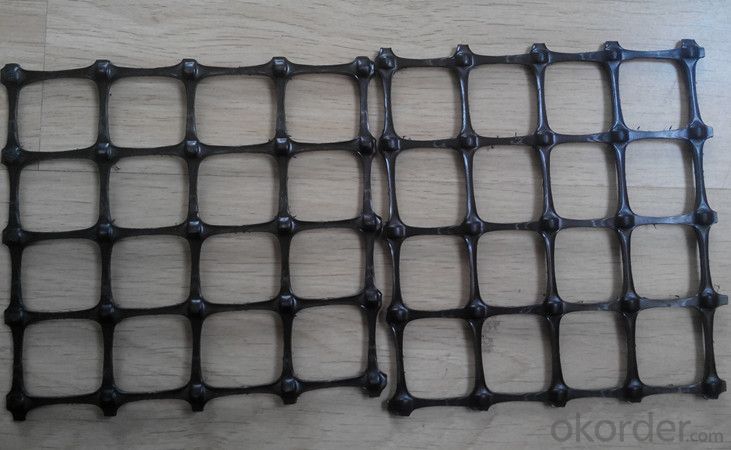

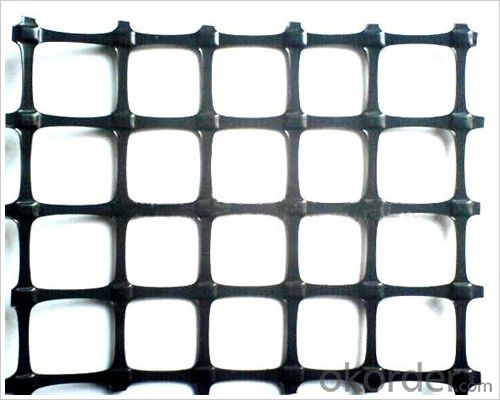

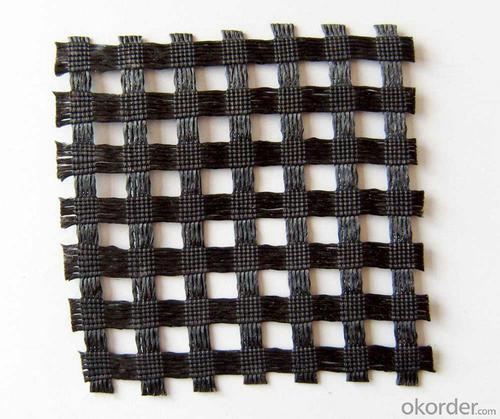

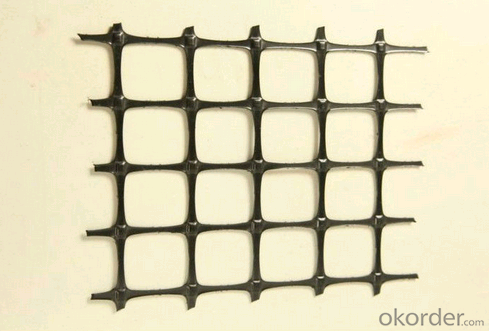

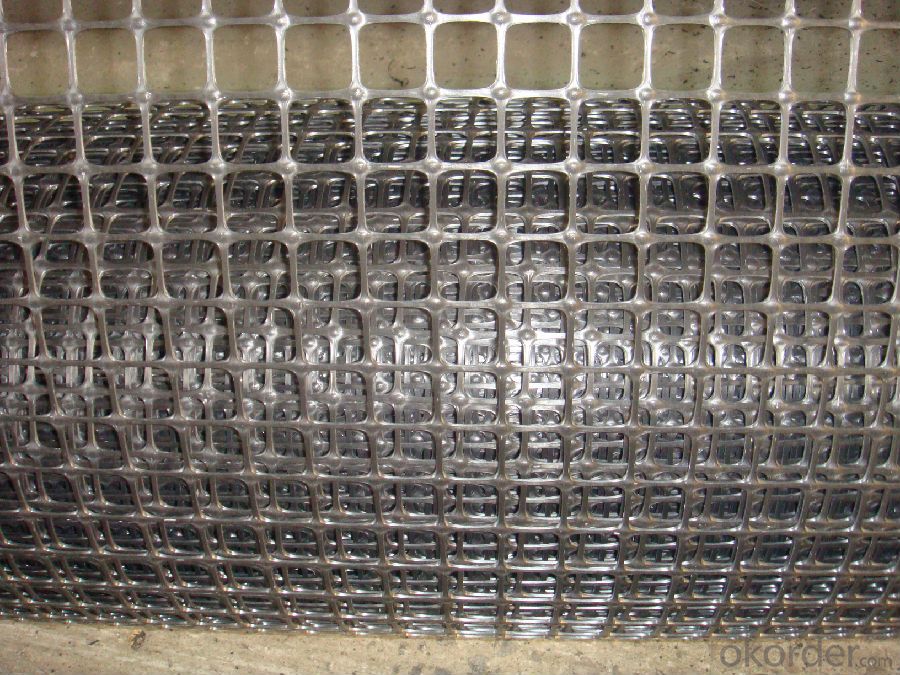

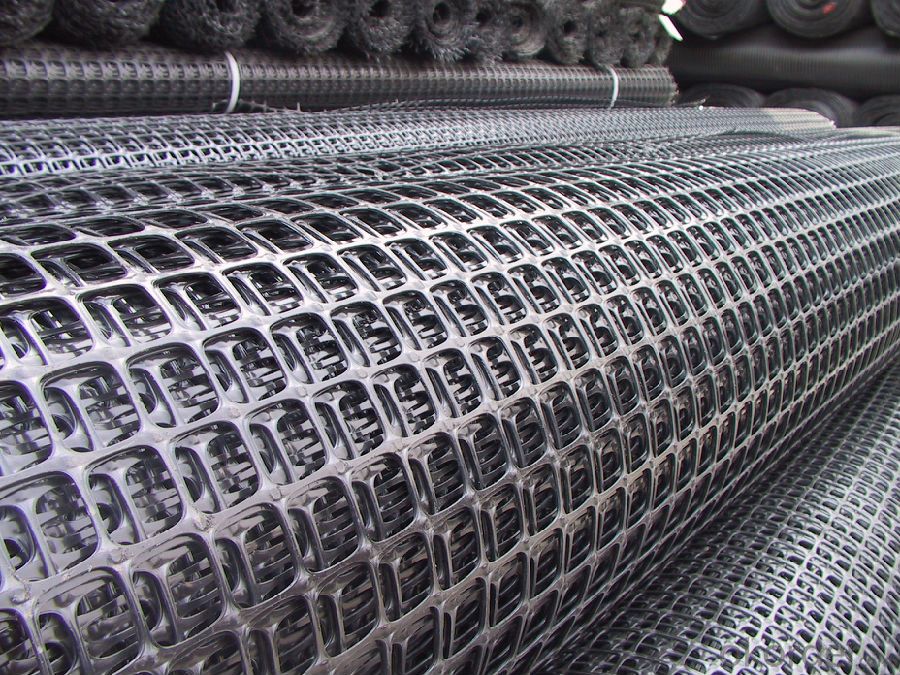

Interlock Plastic Biaxial Geogrids / Polypropylene Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing reinforcement to the soil, increasing its stability and resistance to external forces such as water flow or wind. The geogrids are typically made of high-strength materials and are placed within the soil, creating a network of interlocking structures that enhance the soil's load-bearing capacity. This prevents the soil from being easily displaced, maintaining its integrity and reducing erosion.

- Q: How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offer several advantages over other methods. They provide excellent tensile strength, allowing them to distribute loads and restrain soil movement effectively. Unlike traditional methods like soil nails or ground anchors, geogrids can be installed quickly and easily, reducing construction time and costs. Additionally, geogrids are resistant to chemical and biological degradation, making them a durable and long-lasting solution. Overall, geogrids offer superior performance, cost-effectiveness, and ease of installation compared to other soil reinforcement methods.

- Q: Can geogrids be used for slope stabilization?

- Yes, geogrids can be used for slope stabilization. Geogrids are engineered materials made from polymers that are used to reinforce and stabilize slopes. They are typically installed in a grid-like pattern and provide strength and stability to the soil, preventing erosion and reducing the risk of slope failure.

- Q: EG90R what is the geogrid material?

- One way pull plastic geogrid, also called one-way plastic geogrid

- Q: Can geogrids be used in ground improvement for industrial facilities?

- Yes, geogrids can be used in ground improvement for industrial facilities. Geogrids are commonly used in construction to stabilize and reinforce soils. They can be installed to enhance the load-bearing capacity of the ground, control settlement, prevent soil erosion, and improve the overall stability of the site. In the case of industrial facilities, where heavy machinery and equipment may be present, geogrids can provide a cost-effective and efficient solution for ground improvement, ensuring the safety and stability of the infrastructure.

- Q: What is the number of tensile elements of Geotextiles

- The tensile unit number of geotextiles: the strength of the geotextile under the action of a certain width of 1 meters. KN/m

- Q: How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the clay liner. They help distribute the loads more evenly, reduce soil movement, and prevent erosion by reinforcing the liner's tensile strength. This enhances the overall effectiveness and longevity of the erosion control system.

- Q: Is it the same thing as two way tgsg30-30 geogrid and two - way plastic geogrid

- Can be said to refer to the same thing.

- Q: How do geogrids enhance the performance of geosynthetic clay liner drainage systems?

- Geogrids enhance the performance of geosynthetic clay liner drainage systems by providing additional reinforcement and stability to the clay liner. They prevent the clay liner from being displaced or deformed under heavy loads or high water pressures, thereby improving its overall effectiveness in controlling water flow.

- Q: The dam is protection of geomembrane or gabion.

- There is a need to gabion can call ID

Send your message to us

Interlock Plastic Biaxial Geogrids / Polypropylene Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords