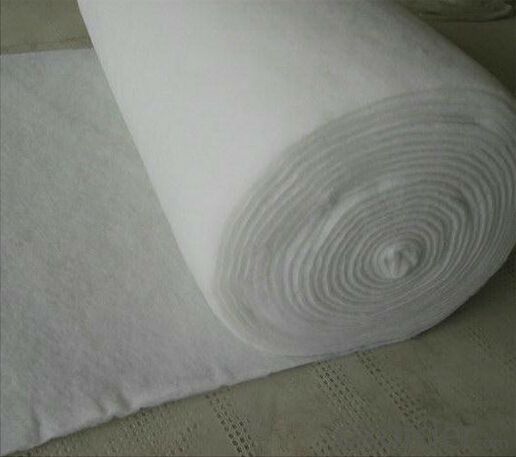

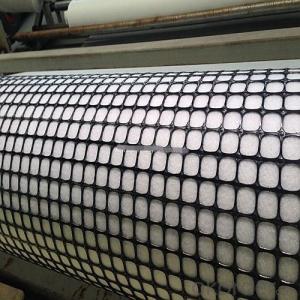

High Quality Nonwoven Geotextile Professional Interlock Biaxial Geogrids Geotextile Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first clearing and preparing the site, followed by laying a layer of geotextile fabric over the prepared area. The geogrid is then unrolled and placed on top of the fabric, ensuring proper alignment and overlap. The edges of the geogrid are secured using pins or stakes. Finally, the geogrid is covered with additional layers of soil, aggregate, or asphalt, depending on the specific project requirements.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are commonly employed to reinforce and stabilize soil structures, including mining tailings. They can help in preventing soil erosion, providing stability to the tailings dam, and improving overall tailings management.

- Q: Glass fiber mesh cloth.

- Mesh is based on alkali or alkali glass fiber yarns, the alkali resistant polymer emulsion coated glass fiber mesh cloth series products: GRC alkali resistant fiberglass mesh cloth, alkali resistant wall enhanced special mesh and stone mosaic, marble back mesh cloth

- Q: How do geogrids improve the performance of geocell-reinforced slopes for erosion control?

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both types of geosynthetics used in civil engineering, but they differ in terms of composition, function, and application. Geogrids are typically made of high-strength polymer materials, such as polyester or polypropylene, and are designed to provide reinforcement and stabilization to soil or aggregate layers. They have a grid-like structure with open apertures that allow for soil interlocking, enhancing the load-bearing capacity of the soil. Geogrids are commonly used in applications such as retaining walls, road construction, and erosion control. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of natural sodium bentonite clay sandwiched between two geotextile layers. The clay layer acts as a hydraulic barrier, providing excellent seepage control and preventing the migration of liquids or gases. GCLs are often employed in environmental containment systems, such as landfill liners or caps, and in other applications that require effective containment of fluids. In summary, while geogrids primarily focus on reinforcement and stabilization of soil, geosynthetic clay liners specialize in seepage control and containment. Their differing compositions and functions make them suitable for distinct engineering purposes.

- Q: Are geogrids effective in reducing differential settlement?

- Yes, geogrids are effective in reducing differential settlement. Geogrids provide reinforcement to the soil, increasing its strength and improving load distribution. This helps to minimize differential settlement by preventing uneven settling of the ground.

- Q: How many square meters of steel plastic geogrid inspection

- The materials of the steel and plastic geogrid need to pass the factory certificate and the inspection report of the manufacturer, and the inspection batch shall be tested by 10 thousand square meters for the base number of 1 times.

- Q: What is the use of glass fiber grille paving asphalt road

- Silicon oxide is an inorganic material, its physical and chemical properties are very stable, and has the advantages of high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep

- Q: Are geogrids suitable for use in ground reinforcement for agricultural facilities?

- Yes, geogrids are suitable for use in ground reinforcement for agricultural facilities. Geogrids provide excellent soil stabilization, erosion control, and load-bearing capacity, making them effective in preventing soil compaction, improving drainage, and supporting heavy machinery used in agricultural operations. Moreover, geogrids are resistant to weathering and have a long lifespan, making them a reliable choice for long-term use in agricultural facilities.

- Q: Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids are specifically designed to improve the stability and strength of soil and can effectively distribute loads, reduce settlement, and prevent lateral movement. They are commonly used in railway construction and maintenance projects to enhance the performance of subgrades by providing additional support and increasing load-bearing capacity.

Send your message to us

High Quality Nonwoven Geotextile Professional Interlock Biaxial Geogrids Geotextile Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords