Aluminum Design Sheets for Pressure Vessels - Best Price Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Pessure Vessels Aluminum Plate Description:

3series alloy also name AL-Mn alloy,since 1.0-1.5% Manganese element in this alloy.The feather of 3series alloy is anti rust. The strength of this alloy is not high(slightly higher than 1series. And 3series alloy can't be heat treatment. So the use of cold processing method to improve its mechanical properties: in the annealing state has a very high plasticity, in the semi cold work hardening is good, corrosion resistance is good,

good welding performance, can be cutting performance.

2.Main Features of Pessure Vessels Aluminum Plate:

PVC Protect Film

Waterproof paper

Good Corrosion Resistance

Good Welding Performance

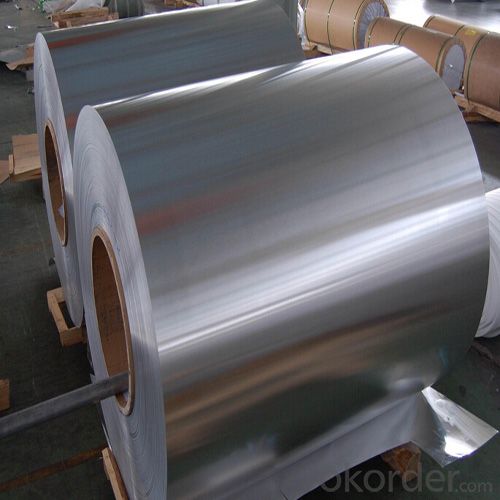

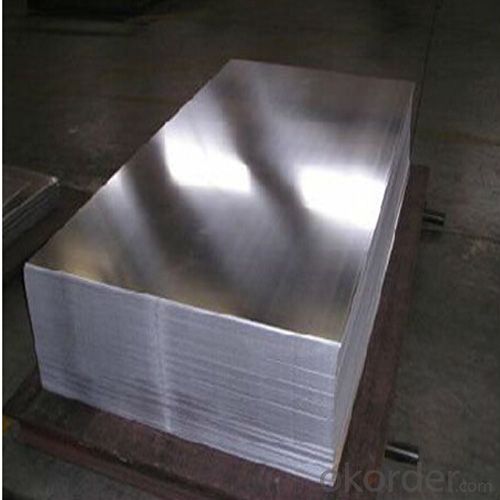

3. Pessure Vessels Aluminum Plate Images:

4. Pessure Vessels Aluminum Plate Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 2-12mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the

details. All the press machines we use is the best quality in China Yangli brand. The

press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with

customer. Our professional mechanical enginners from Austria will design the mould

according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we

can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and

cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you

offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut,

which makes the mould more accurate and precise. Important materials likestainless steel

parts we make in Austria. We also recut after heat treatment, which most of makers do not

take this process.

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q: 1mm aluminum sheet, stamping, die opening, how much is it?

- Just call the mold factory and know that it should be very, very cheap

- Q: Can the aluminum sheets be used for manufacturing electrical conductors?

- Yes, aluminum sheets can be used for manufacturing electrical conductors. Aluminum is a highly conductive metal, second only to copper in terms of electrical conductivity. It is widely used in various electrical applications, including power transmission lines, electrical cables, and wiring. Aluminum sheets can be rolled or extruded into different shapes and sizes to suit specific conductor requirements. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective compared to other conductive materials, making it a popular choice for electrical conductor manufacturing.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: Can aluminum sheets be used for structural purposes?

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and highly malleable material that can be easily fabricated into various shapes and sizes. It has excellent strength-to-weight ratio, making it suitable for structural applications where weight reduction is a priority. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction for making structural components like panels, beams, and frames. Additionally, aluminum has good corrosion resistance, which further enhances its suitability for structural purposes, especially in outdoor or marine environments. Overall, aluminum sheets offer a reliable and cost-effective solution for structural applications.

- Q: Can aluminum sheets be used for automotive heat shields?

- Yes, aluminum sheets can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and heat resistance properties. It has a high melting point and can effectively dissipate heat, making it suitable for protecting various components from excessive heat exposure. Additionally, aluminum sheets are lightweight and easy to shape, allowing for custom designs to fit specific automotive applications. Overall, aluminum sheets are a reliable and cost-effective option for automotive heat shields.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Advantages Of Aluminium

- Q: Can aluminum sheets be powder coated?

- Indeed, it is possible to powder coat aluminum sheets. Powder coating, a widely utilized technique for achieving a sturdy and appealing finish, entails the application of dry powder to surfaces, specifically aluminum, followed by heat treatment. Aluminum is a favored choice for powder coating, owing to its lightweight, corrosion-resistant, and adaptable properties. Through the powder coating process, aluminum sheets acquire a flawless, uniform, and enduring surface. Moreover, this method offers an extensive array of color choices and finds extensive utility in architectural, automotive, and industrial settings.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

Send your message to us

Aluminum Design Sheets for Pressure Vessels - Best Price Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords