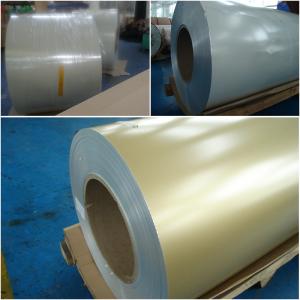

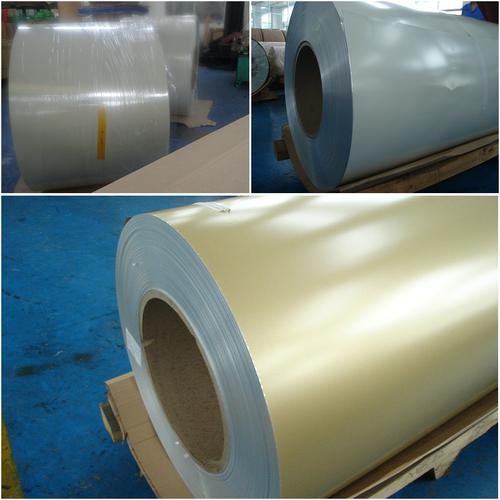

Wood Grain Aluminum Coil Stock - PE Prepainted Aluminum Alloy Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: How do aluminum coils contribute to noise isolation?

- There are multiple ways in which noise isolation can be enhanced with the help of aluminum coils. To begin with, the utilization of aluminum as a material for coils offers exceptional thermal and electrical conductivity, facilitating the dispersion of heat and electromagnetic interference. This, in turn, diminishes the likelihood of noise generated by these factors. Furthermore, noise isolation can be improved by designing aluminum coils with specific properties. By employing thicker aluminum wire, the coil's resistance can be increased, thereby reducing the transmission of electrical noise. Moreover, optimizing the shape and size of the coil can minimize vibrations and resonance, common sources of noise. In addition, the integration of aluminum coils with other noise isolating materials can yield beneficial results. For instance, combining them with acoustic foam or other sound-absorbing materials can create a barrier that prevents sound transmission. The aluminum coil serves as a structural support, while the additional materials absorb and dampen sound waves, further enhancing noise isolation. In conclusion, aluminum coils contribute to noise isolation by dispersing heat and electromagnetic interference, minimizing vibrations and resonance, and providing structural support for other noise isolating materials.

- Q: Can aluminum coils be used for thermal insulation purposes?

- No, aluminum coils cannot be used for thermal insulation purposes.

- Q: What is the typical hardness of aluminum coils?

- The typical hardness of aluminum coils can vary depending on the specific alloy and temper used, but generally falls within the range of 40-70 on the Rockwell B scale.

- Q: Is it possible to utilize steel wires in the creation of jewelry or decorative items?

- <p>Yes, you can use steel wires for making jewelry or decorations. Steel wires are durable and can be shaped into various forms, making them suitable for a range of designs. They are often used in wire wrapping techniques and can be combined with beads or other materials. However, it's important to consider the type of steel used; stainless steel is more resistant to rust and is commonly preferred for jewelry making. Additionally, steel wires may require special tools for cutting and bending, and proper safety measures should be taken during the crafting process.</p>

- Q: Can aluminum coils be welded or joined together?

- Yes, aluminum coils can be welded or joined together. Welding is a common method used to join aluminum coils, especially in industries such as automotive, aerospace, and construction. There are different welding techniques that can be employed, such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and spot welding. These methods allow for the creation of strong and durable joints between aluminum coils. Additionally, other joining methods like adhesive bonding or mechanical fastening can also be used depending on the specific application requirements. Overall, with the appropriate welding or joining technique, aluminum coils can be effectively and securely joined together.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Architectural roofing systems can indeed make use of aluminum coils. The popularity of aluminum as a roofing material stems from its many advantages. To begin with, aluminum is lightweight, making it easy to handle during installation and decreasing the burden on the building's structure. Furthermore, aluminum is highly durable and resistant to corrosion, ensuring that it will last for a long time as a roofing option. Its exceptional thermal properties are worth noting as well, as it can reflect heat and lead to reduced energy consumption. Another advantage is the ease with which aluminum coils can be molded and shaped into various profiles and designs, allowing for flexibility in architectural styles. Lastly, aluminum is an environmentally friendly choice for roofing systems, as it is both recyclable and sustainable. In conclusion, aluminum coils are a practical and suitable choice for architectural roofing systems, offering durability, versatility, and energy efficiency.

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- If you are using a frying pan on a gas stove - yes. I fold tin foil into a strongish ribbon then form the shape I want: hearts, gingerbread men, etc. Make sure the pan is fairly warm before you put the tin foil shape in remove the shape as soon as the pancake is set, but before you flip it. You can trim the little splashes before serving. HOWEVER - there are reusable shapes available at many kitchen supply stores. They are not very expensive are permanent additions to your kitchen.

- Q: What is the weight of aluminum coils?

- The weight of aluminum coils can differ based on their specific dimensions and thickness. Nevertheless, the average weight of aluminum coils can span from a few hundred pounds to several thousand pounds. It is crucial to consider that the weight of aluminum coils can also be affected by factors like the composition of the alloy and any extra coatings or treatments applied to them.

- Q: How do aluminum coils contribute to the energy efficiency of products?

- Aluminum coils play a crucial role in enhancing the energy efficiency of various products. Firstly, aluminum is known for its excellent thermal conductivity, which allows for efficient heat transfer. This characteristic enables aluminum coils to quickly and effectively transfer heat between different components within a product, such as in air conditioning systems or refrigerators. By efficiently dissipating heat, aluminum coils help these products operate more efficiently, reducing energy consumption and ultimately saving costs for consumers. Additionally, aluminum is a lightweight material, which makes it easier to incorporate into various products without adding unnecessary weight. This is particularly beneficial for industries such as automotive and aerospace, where reducing weight is essential for improving fuel efficiency. By using aluminum coils in these applications, manufacturers can achieve lighter and more energy-efficient vehicles or aircraft, resulting in reduced fuel consumption and emissions. Furthermore, aluminum coils offer excellent corrosion resistance. This is especially advantageous in products exposed to moisture or harsh environments, as it prevents rust and degradation over time. By maintaining the performance and integrity of the coils, the overall energy efficiency of the product is preserved, ensuring that it operates optimally for an extended period. In conclusion, aluminum coils contribute significantly to the energy efficiency of products through their thermal conductivity, lightweight properties, and corrosion resistance. By effectively transferring heat, reducing weight, and preventing degradation, these coils help products operate more efficiently, resulting in lower energy consumption, cost savings, and reduced environmental impact.

- Q: What are the potential applications of pre-painted aluminum coils?

- Pre-painted aluminum coils have a wide range of potential applications due to their versatility and durability. One potential application is in the construction industry, where pre-painted aluminum coils can be used for roofing and cladding. The pre-painted coating provides an attractive and protective finish, making it ideal for both residential and commercial buildings. Additionally, aluminum is lightweight, which makes it easier to install and transport. Another potential application is in the manufacturing of appliances and electronics. Pre-painted aluminum coils can be used to create outer casings for various appliances, such as refrigerators, ovens, and air conditioners. The coating provides a smooth and aesthetically pleasing finish, while the aluminum itself offers excellent heat dissipation properties. Pre-painted aluminum coils also find applications in the automotive industry. The durable coating helps protect the surface of the vehicle from scratches, UV rays, and corrosion. Additionally, aluminum is lightweight, which can contribute to fuel efficiency and improved performance. In the signage industry, pre-painted aluminum coils are commonly used for outdoor and indoor signage. The coating provides a long-lasting and vibrant finish, making it suitable for a variety of signage applications, such as billboards, store signs, and traffic signs. Furthermore, pre-painted aluminum coils can be employed in the manufacturing of furniture and fixtures. The coating adds a decorative touch to furniture pieces, while the aluminum provides strength and stability. This makes pre-painted aluminum coils suitable for items such as cabinets, shelves, and decorative panels. Overall, the potential applications of pre-painted aluminum coils are vast and diverse. Their versatility, durability, and attractive finish make them suitable for various industries, including construction, manufacturing, automotive, signage, and furniture.

Send your message to us

Wood Grain Aluminum Coil Stock - PE Prepainted Aluminum Alloy Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords